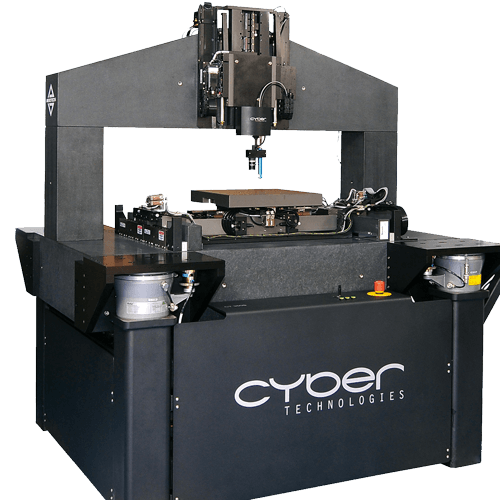

The CT 350S is a non‑contact profilometer with a 350 mm x‑, y‑scanning stage and a closed loop 200 mm z‑axis. All 3 axis use air bearings and magnetic linear motors.

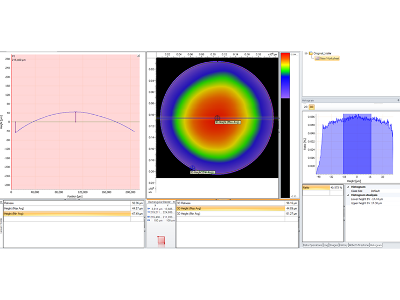

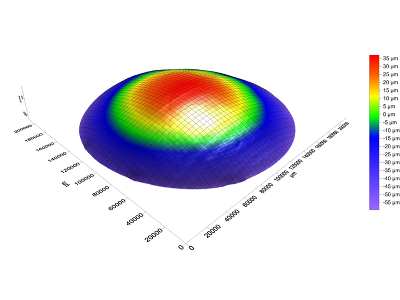

The system is based on a massive granite construction with a vibration isolated floor stand. The x‑y motion system offers exceptional performance with an error of less than 100 nm. During the scanning process the z‑axis can follow the shape of the part. The height reading is a combination of the calibrated z encoder signal and the sensor height. This allows the system to achieve a very high resolution over the entire z‑axis range of 200 mm.

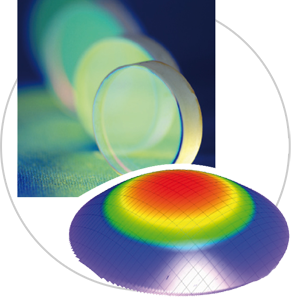

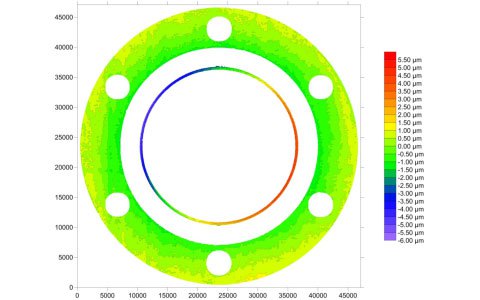

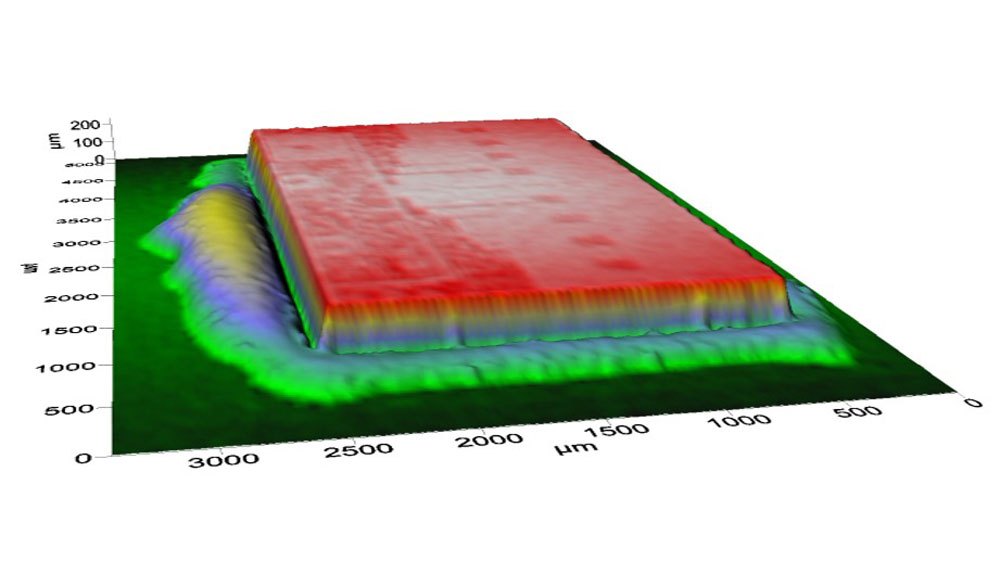

The CT 350S was originally designed and is ideal for measuring precision optics. However, contour measurements, step height, roughness and other 2D and 3D analyses are excellent examples of further applications. The sensors are available with a resolution down to 3 nm.