In close partnership between Accelonix and one of the leading microelectronics assembly companies in the Netherlands we are able to offer local dicing services.

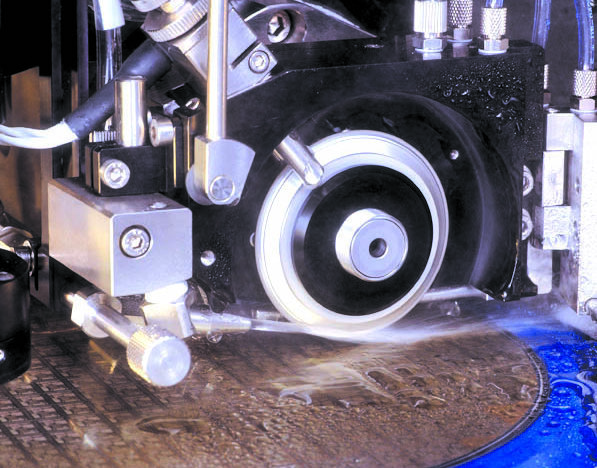

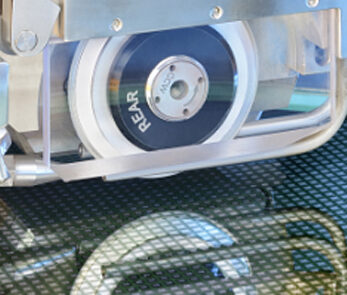

Located in a fully equipped ISO class 8 cleanroom, our experienced dicing engineers use ADT 7200 Series Full Automatic Dicing Saws.

Capabilities:

- Wafer / substrate mounting on Dicing Tape

- Full Automatic Dicing System

- Wafers and substrates up to 8″ inch in diameter

- Full automatic pattern recognitions for the most accurate cutting map generate.

- High accurate axes for the highest cut quality to deliver industry standard quality

- Atomizing Cleaning Technology

- UV-Station for Dicing tape release.

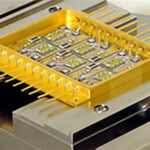

Leading applications:

- PCB

- QFN

- BGA Panels

- Silicon Wafers

- SAW Filters

- LED Packages

- Ceramic substrates

- Thin Film Devices

- Glass Wafers, IR Filters

- PZT transducers

- Many more..