The new AP+ marks the latest generation of automated die sorter from Royce Instruments, designed to address the needs of engineers seeking a user-friendly flexible tool capable of handling the most varied and complex sorting requirements.

A Highly Flexible System Capable of Quickly Changing Between Different Inputs and Outputs

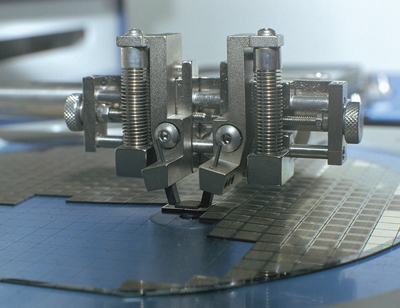

Choose from wafer on tape, waffle pack, Gel-Pak®, JEDEC tray or your own custom tray with or without a wafer map. 180 degree die inversion, optical inspection and a wide variety of output fixtures including placement to tape and reel are available. Full input to output die level traceability is maintained for all combinations of input and output fixtures

Addressing Today’s Challenging Die Sort Applications

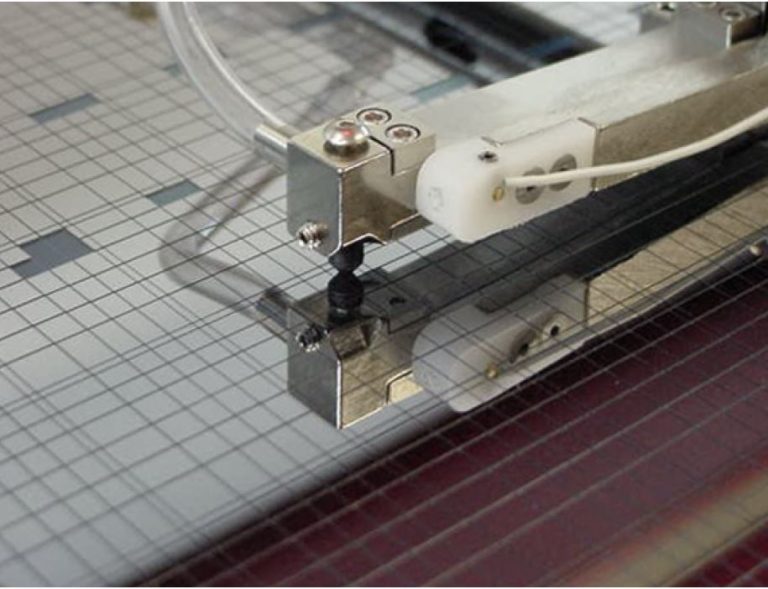

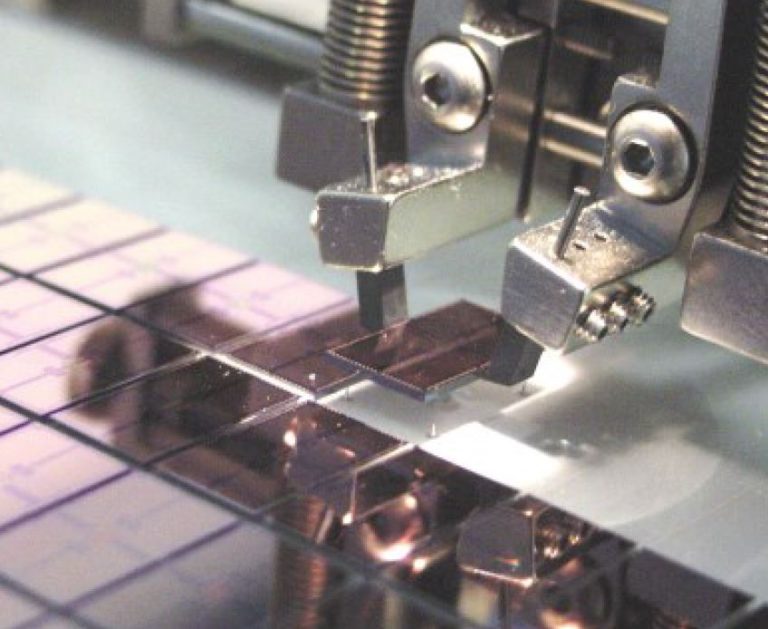

Quick change tooling allows a wide variety of processes to be handled on a single system. The non-surface contact edge grippers allow MEMs and optical devices with sensitive surfaces to be handled without touching or applying vacuum to the top of the device, while customizable eject heads and pick-up tools allow die as thin as 50 micron thick GaAs with air bridges and vias to be successfully processed. Integrated wafer mapping software allows wafers with multiple die sizes (multi-project/Pizza mask wafers) to be easily processed. With the wafer map file support option, customers can load their map file directly into the AP+, or the built-in map creator can be used to create a map for untested wafers.

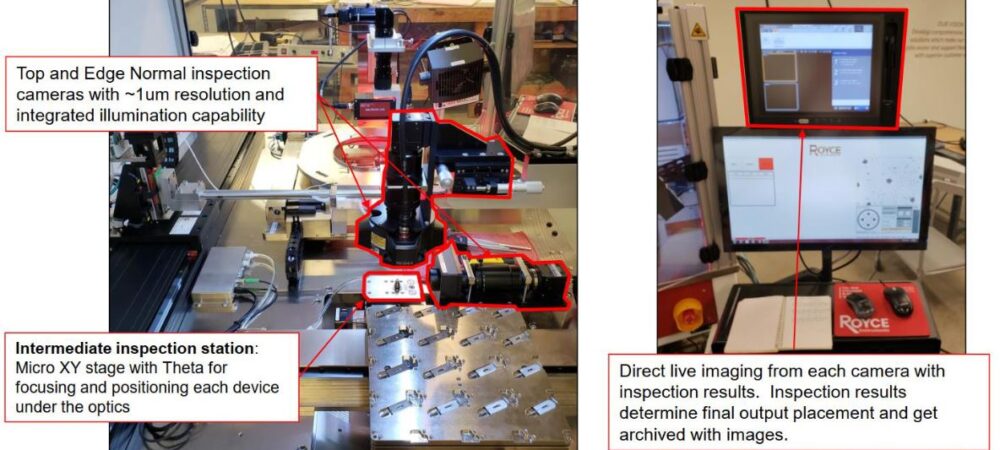

Automatic Inspection