ELECTRONICS INSPECTION

|

|

|

|---|

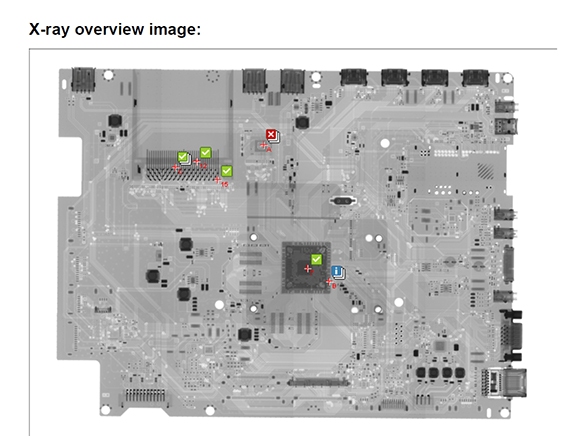

Typical inspection tasks include:

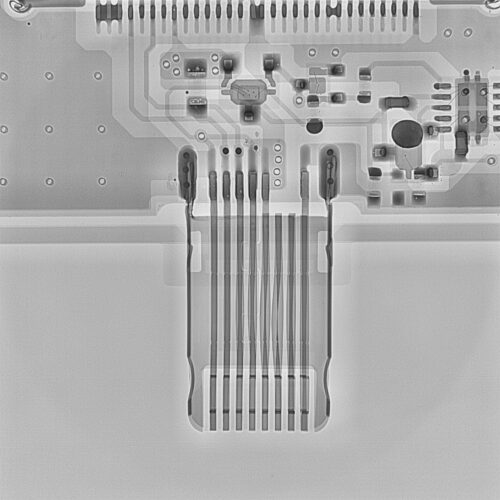

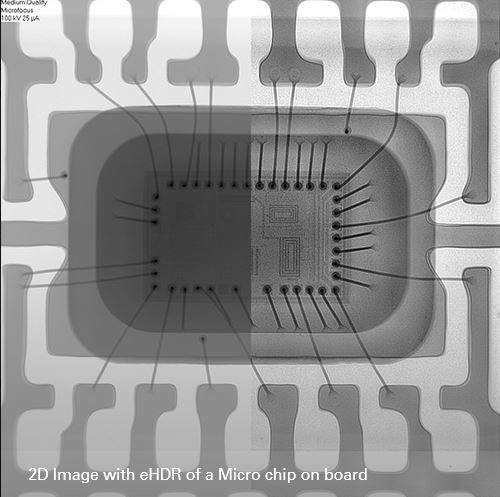

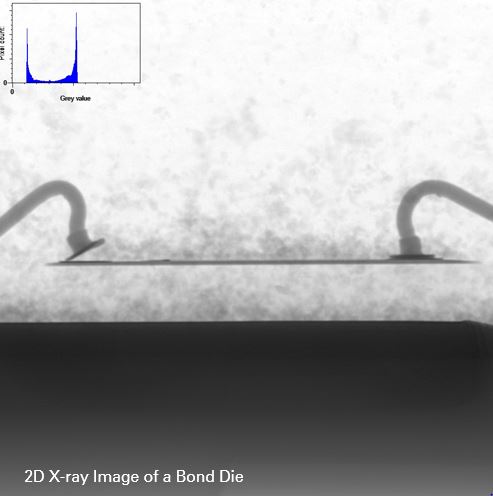

• Testing of bond wires and bonding areas

• Cavity analysis conductive and non-conductive chip bonding compounds

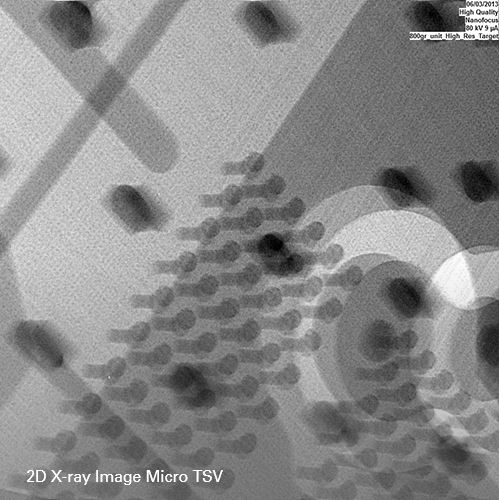

• Testing of 3D integrated circuits (IC) solder joints (micro bumps, copper pillars, Through-Silicon Vias (TSV))

• Analysis of discrete components such as capacitors and coils

It is important to find cracks, open solder joints or voids via X-ray inspection. Additionally the measurement of pore sizes and their distribution is critical. Many of these inspections are performed automatically by the YXLON inspection systems for an improvement in the production process.

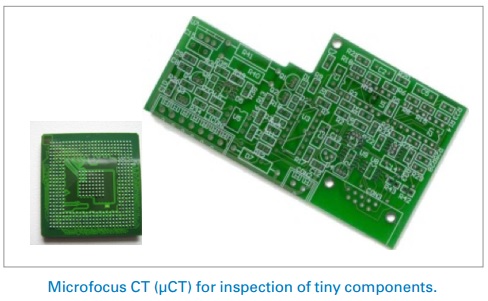

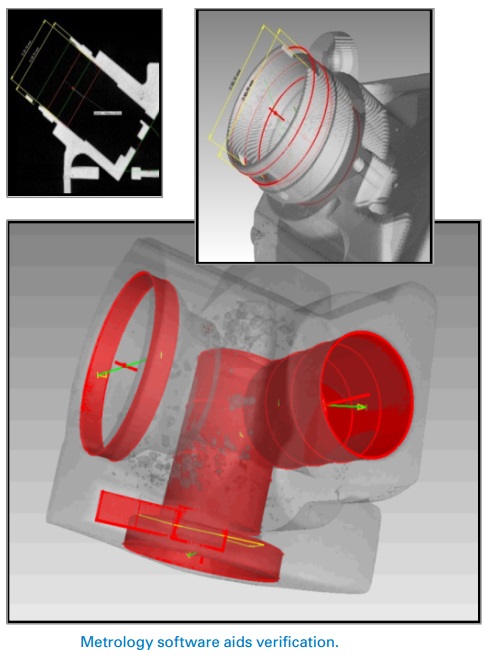

The YXLON CT systems provide the highest resolution 3D non-destructive failure analysis of semiconductor devices.

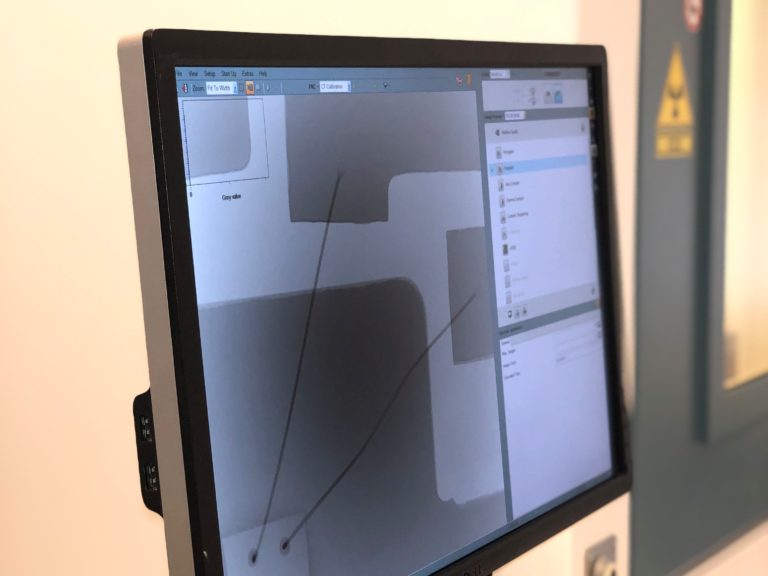

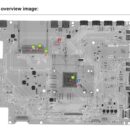

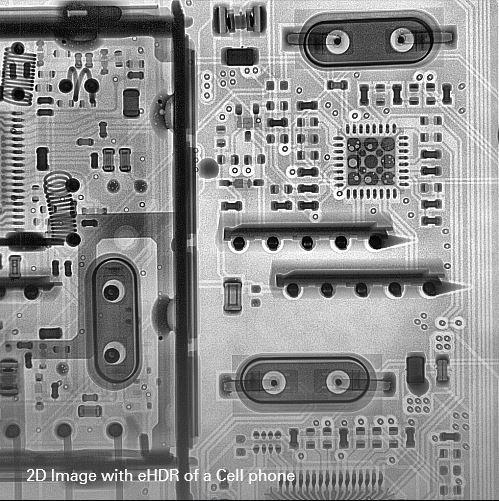

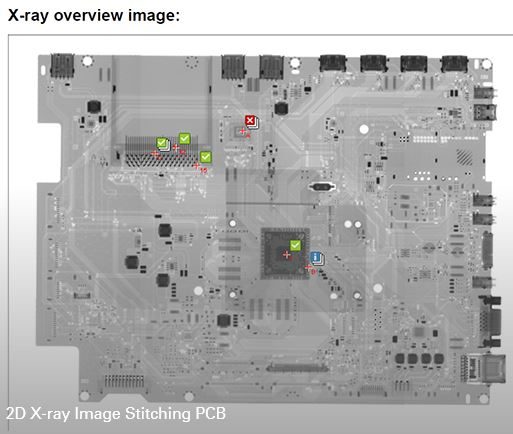

YXLON X-ray inspection technology is used in the production of multilayer printed circuit boards to measure the position offset and minimal residual ring width. High quality X-ray images in oblique view allow for the detailed observations.

• Visualization of individual layers

• Detection of defects

• Detection of failures

As an example, X-ray imaging can detect etching or layout errors, shorts caused by faulty interconnects and poor metallization of contact holes.

|

|

|

|---|

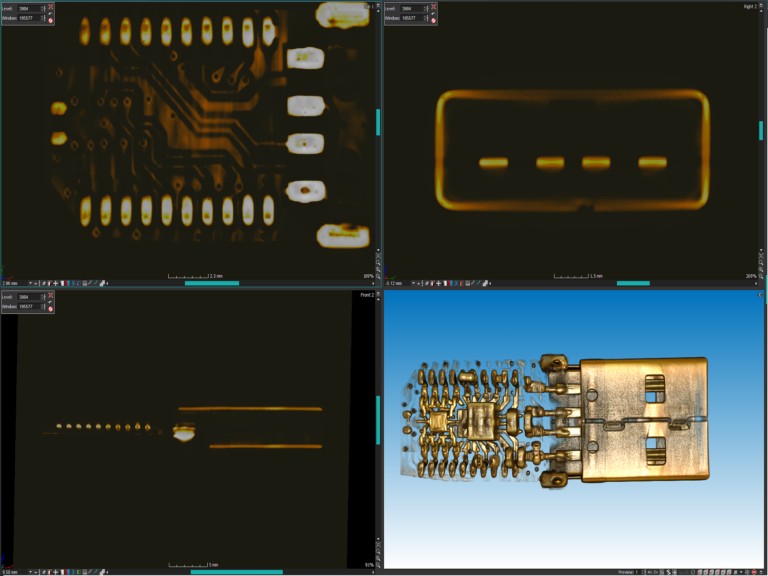

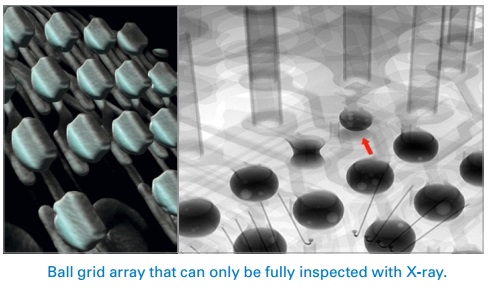

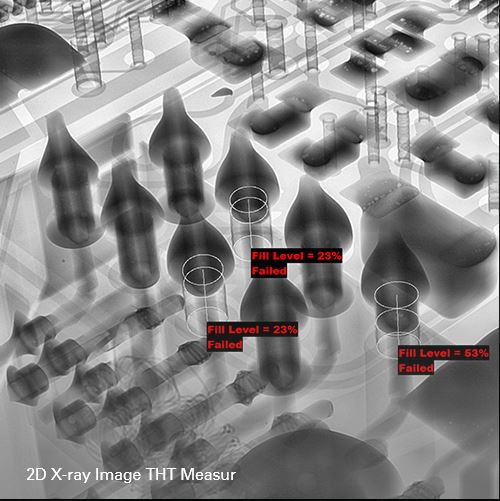

High-resolution YXLON X-ray imaging is widely used in failure analysis and production quality testing of electronic components, such as solder joint inspection. X-ray images help identify material defects and quality characteristics that influence the shape of the solder joint.

• Missing solder fillings

• Missing solder connections

• Solder voids

• Solder bridges

• Mistakes due to lack of wetting

The semi-automatic testing software on YXLON X-ray systems allows for quick and easy ‘teach-in’ programming, as well as the highest fault coverage and repeatability.

|

|

|

|---|

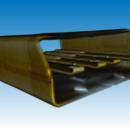

In components for power electronics (i.e. Insulated-Gate Bipolar Transistor (IGBT)) heat is passed over the solder joints to thick copper heat sinks. To achieve optimum heat transfer, the solder joints must be as free of voids as possible.

Although these hybrid components are often found within X-ray absorbing housings of tungsten and copper, which absorb X-rays to a high degree, high-contrast microfocus YXLON X-ray systems and detectors can be successful in solder joint inspection.

This is essential for the automatic calculation of absolute and percentage void size.

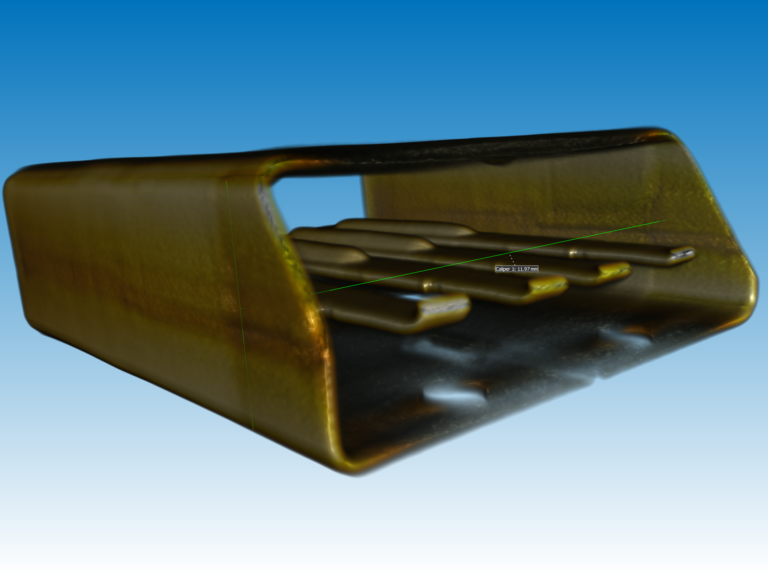

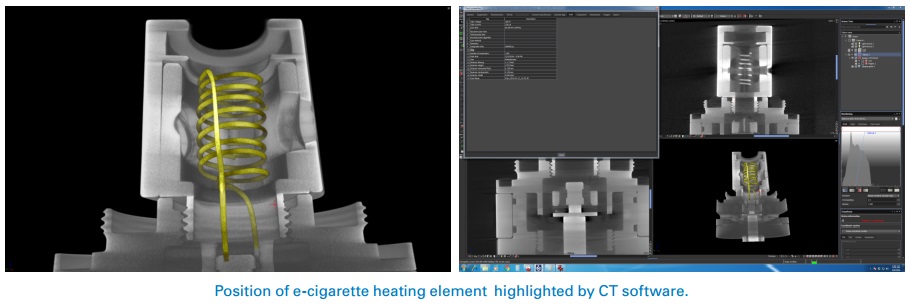

When testing sensors and electronic components, high-resolution YXLON X-ray techniques are used to inspect and to evaluate:

• Contacts

• Joints

• Packages

• Insulators

• Assembly