The Cheetah EVO range was created to achieve a simple goal: the very best image in the shortest time, in each of the electronics market sector

With a modular platform, each system can be customized for any application such as SMT, semiconductor, or laboratory. Users always get the best solution for their specific and demanding application.

Get the right system for your application.

Applications

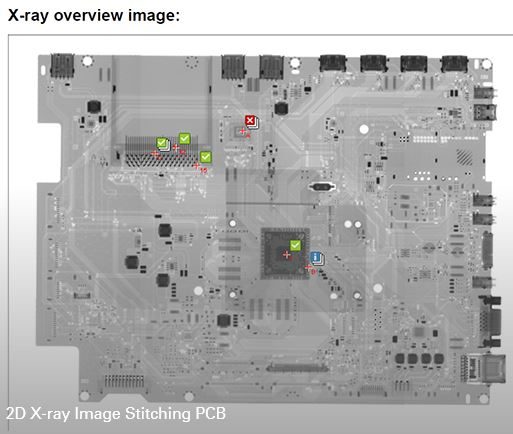

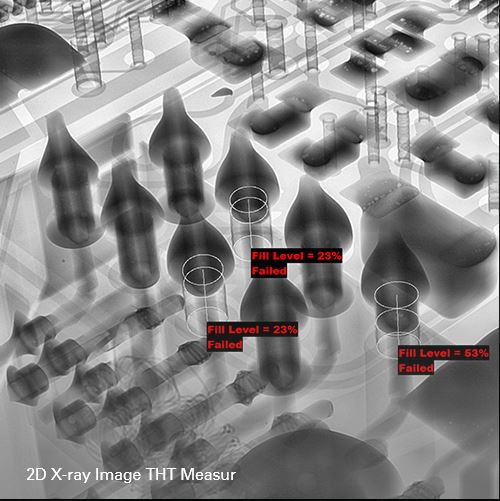

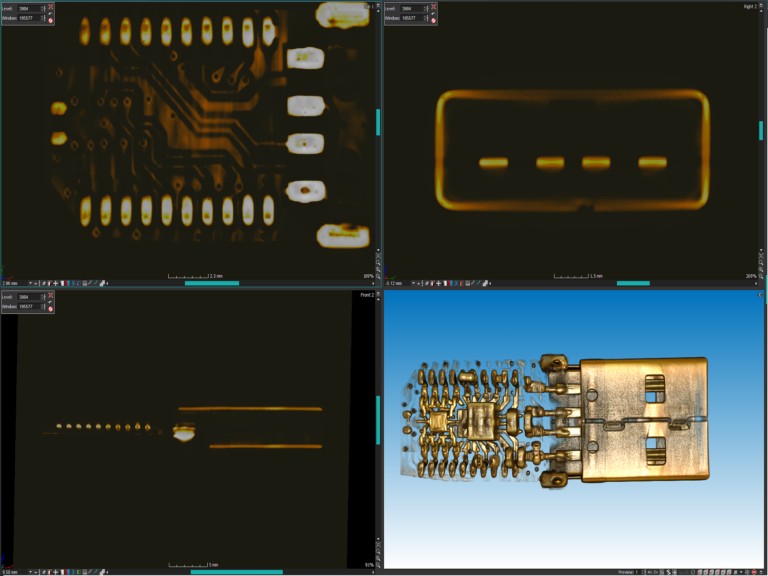

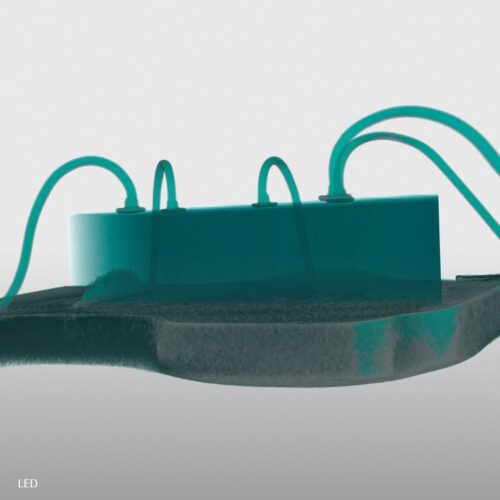

- SMT and PTH assemblies

- PCBs

- IGBTs

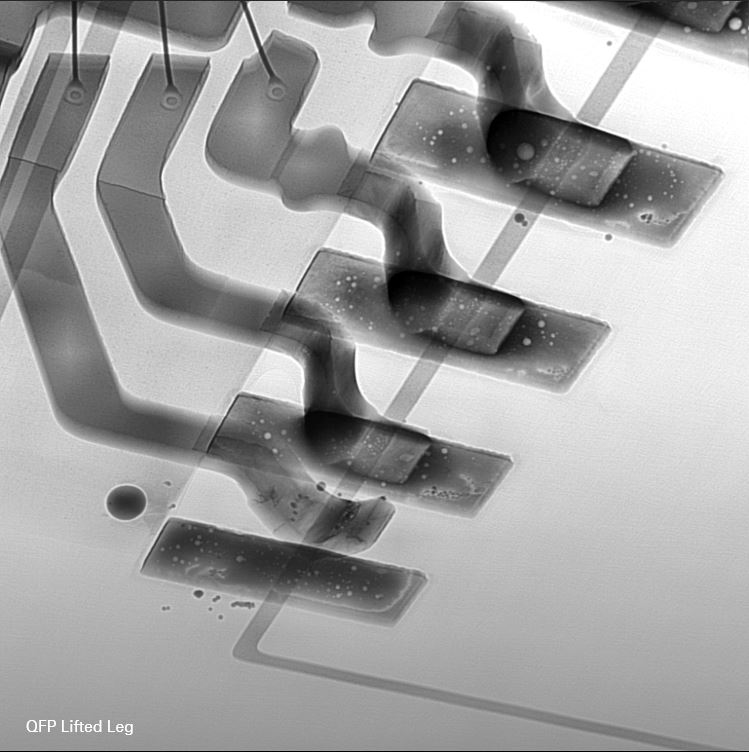

Benefits for SMT

- Accurate, fast, and repeatable inspection – manually and automatically

- High power, high resolution inspection of very small features

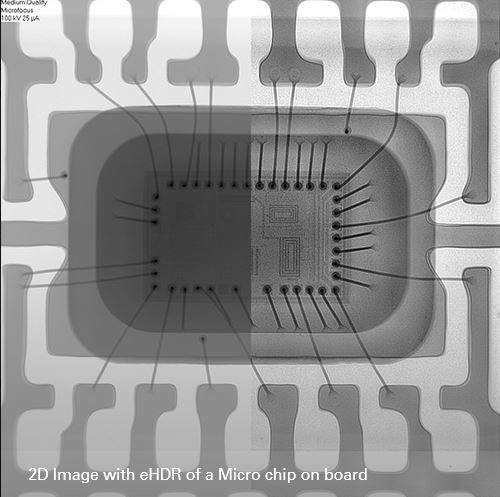

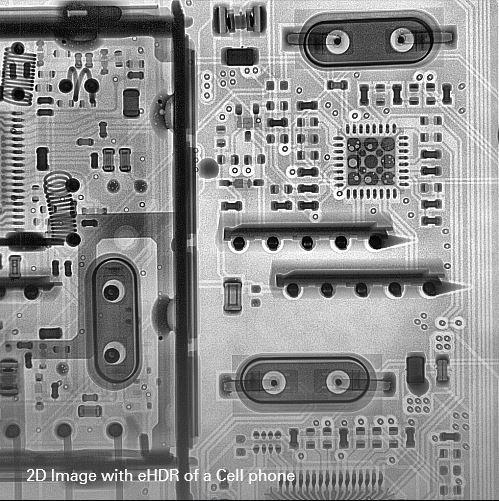

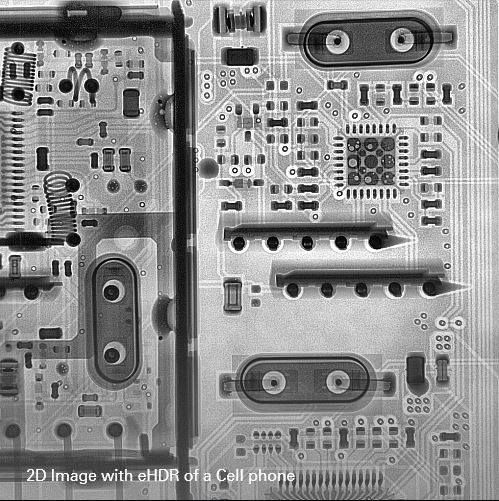

- Easy to use, dynamic image enhancing filters, e.g. eHDR

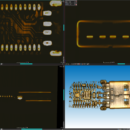

Software

- eHDR-Inspect

- Improved, user friendly FGUI

- Multi Area Void Calculation

- Extended BGA Inspection

- Extended ADR

System Highlights

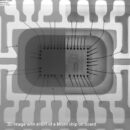

Cheetah EVO SMT harnesses the combined power of several COMET YXLON innovations – FeinFocus X-ray tube technology, High Power Target technology, a finely calibrated, long-life flat-panel detector, and a manipulator with cushioned bearings. The variety of sample tables ensures that it can generate 2D and 3D images in extremely high resolution.

In addition to imaging excellence, you can look forward to simple, user-friendly controls and COMET YXLON FGUI – FeinFocus Graphical User Interface – software, not to mention the myriad benefits of comprehensive automation. One-click solutions make manual inspections effortless, while Easy Teach-In makes it simple to program the automated procedures that guide the operator swiftly through inspections – and deliver repeatable and reliable results.

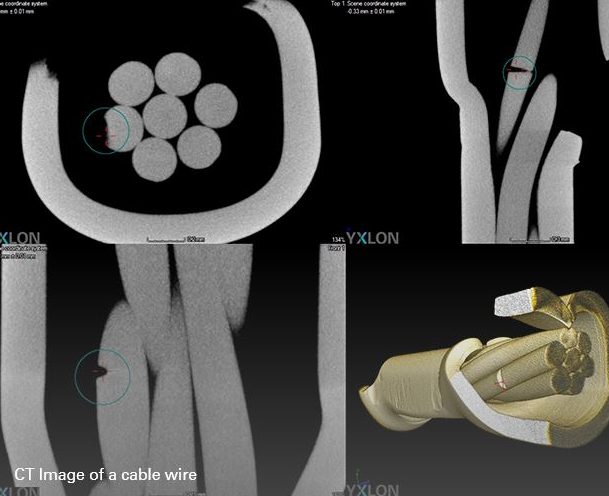

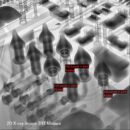

Cheetah EVO SMT can be upgraded for CT with the optional microCT module. This enables CT for industrial quality assurance, with in-depth 3D examination of inspection items via virtual cross sections and layers. With its user-friendly COMET YXLON QuickScan® module, it delivers 3D images and virtual slices within a minute.

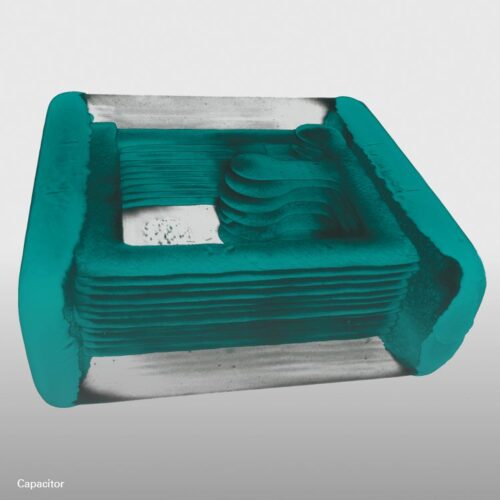

Applications

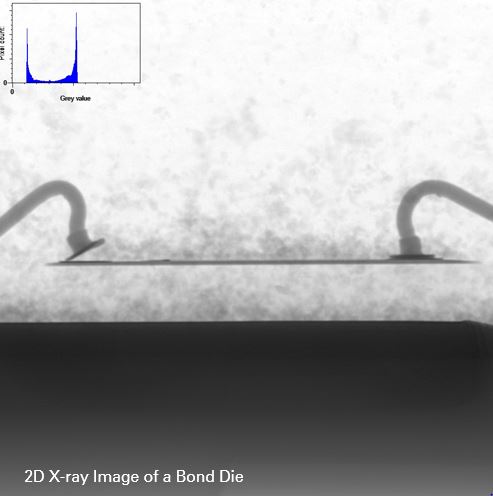

- Wafer inspection

- 3D integrated circuit joints

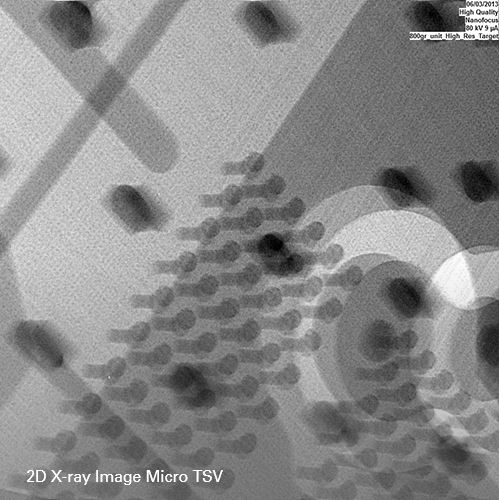

- Microbumps

- Sensors

- MEMS and MOEMS

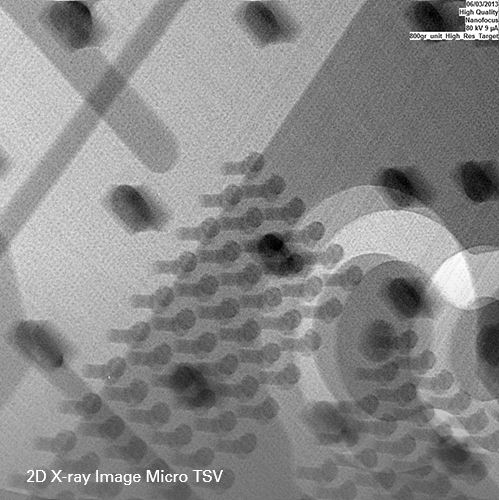

- TSVs

Benefits for Semiconductors

- Accurate, repeatable void compilations, including multi area voiding

- Excellent resolution at low power and low kV

- Fast, automated, easy routines

- Very fast live (on the fly) inspections

Software

- eHDR-Inspect

- User friendly FGUI

- Multi Area Void Calculation

- Extended BGA Inspection

- Extended ADR

System Highlights

Cheetah EVO Semi harnesses the combined power of several COMET YXLON innovations – FeinFocus X-ray tube technology, High Power Target technology, a finely calibrated, long-life flat-panel detector, and a manipulator with cushioned bearings. The variety of sample tables ensures that it can generate 2D and 3D images in extremely high resolution.

In addition to imaging excellence, you can look forward to simple, user-friendly controls and COMET YXLON FGUI – FeinFocus Graphical User Interface – software, not to mention the myriad benefits of comprehensive automation. One-click solutions make manual inspections effortless, while Easy Teach-In makes it simple to program the automated procedures that guide the operator swiftly through inspections – and deliver repeatable and reliable results.

Cheetah EVO Semi can be upgraded for CT with the optional microCT module. This enables CT for industrial quality assurance, with in-depth 3D examination of inspection items via virtual cross sections and layers. With its user-friendly COMET YXLON QuickScan® module, it delivers 3D images and virtual slices within a minute.

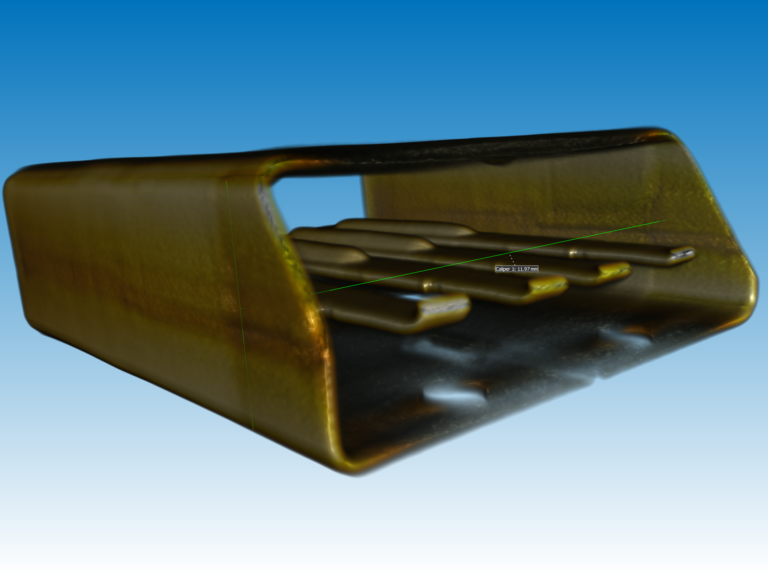

Applications

- Batteries

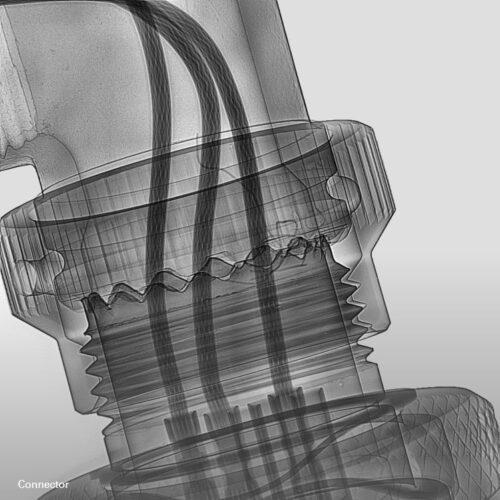

- Connectors

- Various hard-to-see electronic components

- Medical material

- Military and space electronics

Benefits for Laboratory

- Ultimate quality resolution for failure analysis applications

- High-performance CT inspection for all demanding applications

- Highest industry CT reconstructions with VGStudio and Siemens Software

Software

- eHDR-Inspect

- Improved, user friendly FGUI

- CT reconstruction VGStudio and Siemens Software

System Highlights

Cheetah EVO Plus harnesses the combined power of several YXLON innovations – FeinFocus X-ray tube technology, High Power Target technology, a finely calibrated, long-life flat-panel detector, and a manipulator with cushioned bearings. The variety of sample tables ensures that it can generate 2D and 3D images in extremely high resolution.

In addition to imaging excellence, you can look forward to simple, user-friendly controls and YXLON FGUI – FeinFocus Graphical User Interface – software, not to mention the myriad benefits of comprehensive automation. One-click solutions make manual inspections effortless, while Easy Teach-In makes it simple to program the automated procedures that guide the operator swiftly through inspections – and deliver repeatable and reliable results.

Cheetah EVO Plus comes standard with CT and a microCT module. This enables CT for industrial quality assurance, with in-depth 3D examination of inspection items via virtual cross sections and layers. With its user-friendly YXLON QuickScan® module, it delivers 3D images and virtual slices within a minute.