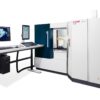

The FF35 CT is a compact, high-resolution computed tomography system ideally suited for inspection of your small to medium sized items such as:

- Electronic components like SMD

- Semiconductor packaging

- Probes of new materials (e. g. metal, plastics, CFRP)

- Microsystems, MEMS, MOEMS

- Medical devices like hollow needle

- Small metal parts i.e. injection molds

- Electronic devices

- Small castings

A key advantage of the powerful FF35 CT is the optional dual-tube-configuration (nano-focus transmission tube and high power micro focus tube), which makes the FF35 CT extremely versatile. Each tube can be adjusted independently at a touch of a button.

Intuitive system control is accomplished via two touchscreens displaying easy to understand graphics. Intelligent functionality supports the user: As an example, ‘IntelliGuard’ avoids collision with X-ray tube and detector by automatically determining the outer-shape of the inspection item during a 360° rotation.

CT trajectories such as ‘HeliExtend’ (helical CT scan and reconstruction method) provide consistently good image quality from top to bottom, and capture elongated specimens with a high magnification scan.

The ability to select your own center of scan rotation using ‘virtual axis rotation’ (FlexCenter) offers considerable comfort and saves time. The inspected item need not be repositioned if regions of interest fall outside the physical center of rotation of interest.

A system health monitor gives you information on various parameters. Results are consolidated and displayed in a ‘traffic light’ representation. Additionally, you can access this health-state of the system and the progress of the CT (and reconstruction) from your office through our remote monitoring software.