As part of the growing market and the ongoing demand to lower the cost of production per unit (CoO), ADT has responded with a single spindle system model 7910 Uno.

The 7910 Uno system provides a perfect solution for standard silicon wafers up to 8” and for low cost discrete devices.

Further to the automatic vision and easy Graphic User Interface (GUI), ADT is offering a machine at small foot print for saving cost on the production floor.

7910 Series Advantages:

- Up to 8” wafer

- Fast automatic alignment and cut positioning increase throughput

- Automatic Kerf inspection increase yield

- Automatic Y offset correction ensures maximum precision

- Single low vibration spindle enable superb cut quality

- Friendly and intuitive GUI

- Touch screen user interface

- Easy to load and unload

- Easy to maintain

- Small footprint reduces cost of ownership

- Price

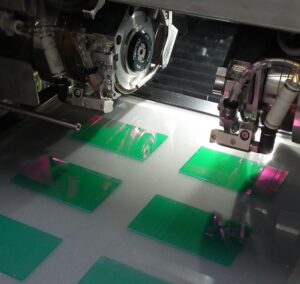

As part of the growing market of the LED segment and the on going demand to lower the cost of production per unit (CoO), ADT has responded with a dual spindle system model 7900 Duo that double the productivity while maintaining the same current production floor space.

The 7900 Duo system provides a perfect solution for applications that require a long cut cycle time such as image sensors and saw devices.

Further to the automatic vision and easy Graphic User Interface (GUI), ADT is offering a unique feature for processing and programming of broken wafers.

7900 Series Advantages:

- Two facing spindles enable simultaneous dicing

- Low vibration platform

- Fast automatic alignment and cut positioning increase throughput

- Small footprint reduces cost of ownership

- Automatic Kerf inspection increase yield

- Automatic Y offset correction ensures maximum precision

- Tape surface detection ensures consistent cut quality

- Touch screen user interface

System Specifications

- Work piece size: 6″ x 6″ or 8″ x 8″

- Blade size: 2″- 3″

- Spindle: Two facing spindle, 60 krpm, 2.5 kW and rated torque of 0.25 Nm

Y1/Y2 Axis

- Drive: Ball bearing lead screw with stepper motor

- Control: linear encoder

- Resolution: 0.2 µm

- Cumulative accuracy: 1.5 µm

- Indexing accuracy: 2.0 µm

- Cutting range: 160mm (6″ x 6″) / 200mm (8″x8″)

X Axis

- Drive: Ball bearing lead screw

- Air bearing slide

- Feed rate: up to 600 mm/sec

- Cutting range: 410mm

Z1/ Z2 Axis

- Drive: Ball bearing lead screw

- Resolution: 0.2 µm

- Accuracy: 2.0 µm

- Repeatability: 1.0 µm

- Stroke: up to 25mm

Ø Axis

- Drive: closed-loop, direct-drive

- Accuracy: 4 arc-sec

- Repeatability: 4 arc-sec

- Stroke: 350 deg.

Vision System

- Digital camera, Fire wire link

- High bright LED illumination (vertical & oblique)

Utilities

- Electrical: 200-240 VAC 50/60 Hz, Single phase

- Air consumption: 260 L/min @ 5.5 bar

- Cutting water (per spindle): 3 L/min

- Spindle water (per spindle): 1.1 l/min

Dimensions (WxDxH):

- 875 x 975 x 1450 mm

- Weight: 900 kg

Features

- Automatic alignment

- Automatic Kerf inspection

- Automatic Y offset correction

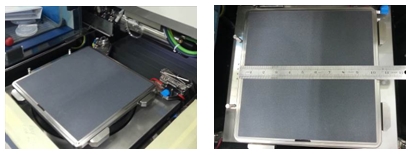

7900 Duo LA (LArge Area)

ADT can provide the 7900 Duo dicing machine with large area cutting capabilities of up to 8” X 10” or 10” X 10”.

The 7900 Duo LA supports multi panels for high throughput.