Akrometrix Studio is an advanced set of integrated software modules that work together to run all Akrometrix equipment. The Studio software suite takes users from profile creation, through warpage measurement, temperature profiling, analysis of warpage data, and reporting seamlessly. Studio software users will have nearly the same experience in working with different Akrometrix measurement technologies and different Akrometrix measurement tools.

The Studio Suite is broken up into a series of programs that work together

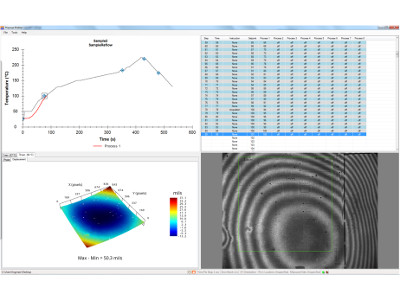

- Create thermal profiles graphically; ‘click’ to add temperature points and actions

- Assign ramp rates, soak times and cool down periods using numerical settings

- Set machine control action points by clicking on profile segments

- Measurement points (capturing phase images)

- Blower on/off points

- Exhaust on/off points

- Work from a live system view to setup multiple test parameters

- Run multiple phase image and 3D measurement results windows concurrently

- View displacement graphs and data when data is acquired

- Work with multiple regions of interest

- DIC, DFP, CRE6, and CM modules integrate seamlessly into the same workflow

- Includes Part Tracking feature and option for Real Time Analysis (RTA) software

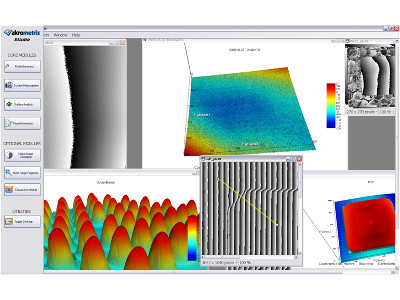

- Analyse and compare 2D and 3D data sets

- View up to 2 million displacement data points on each graph

- Control multiple graphs on-screen at once

- Mask areas and burn masks permanently into phase images

- Calculate one displacement data set relative to another

- Export data for further analysis into computational applications such as ANSYS and MATLAB

- Draw 2D chord lines across phase images at any angle

- Zoom, rotate, crop and export 3D displacement graphs in multiple format

Batch Processing

- apply masks, filters, chords, rotation and other operations to hundreds of phase data sets, provide multiple output and export options for graphical and analytical analyses, and export data for use in Interface Analysis

Surface-mount components warp during the reflow process, and the area where they attach also changes shape during assembly. This interface between components is where solder, paste, and gaps created due to thermal expansion combine to create 100% good products, or defects such as Head-in-Pillow, Shorts, and Opens. Fully understanding that critical interface between surfaces is more important than ever.

While standard Akrometrix software allowed the analysis of an individual surface, such as a PCB or BGA, Interface Analysis is new software that enables 3D, 2D, and statistical review of a complete interface. Users can now visualize and quantify exactly how two surfaces will mate together. By combining this feature with the ability to measure surfaces at each temperature point during reflow, solder joint formation or failure can be predicted much more easily.

Interface Analysis works with data supplied by any of the 250+ TherMoiré systems in use throughout the worldwide Electronics supply chain today. Introducing unique features such as Pass/Warning/Fail maps, and various gap and surface gauge information, Interface Analysis lets users see what is happening between two dynamic surfaces through the reflow process. Applications include SMT Assembly Planning and Troubleshooting, Failure Analysis, Supplier Qualification and Comparison, Ongoing SPC, Package Design, and FEA Modelling Validation.

Two Important application areas are Package-on-Package Design and Assembly and Package-to-PCB Design and Assembly

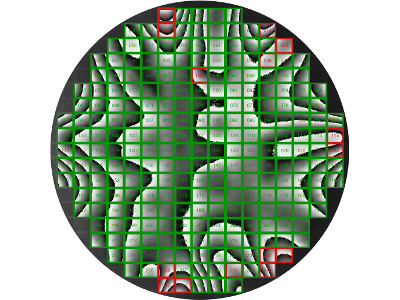

Real Time Analysis (RTA) takes user input warning and failure gauge limits and gives immediate feedback on the region or regions that fall within desires performance. It is based on an easy to use recipe approach for up front processing and RTA is designed to scale to high volume applications, taking the analysis steps out of warpage measurements and going straight to decisions. It scales to hundreds of regions measured in only 2 seconds, gives tabular and visual output to users immediately after measurement.

Part Tracking technology is a software application included in Akrometrix Surface Measurement that increases system throughput while reducing user to user and system to system measurement variation. It automatically locates, crops, and rotates measured samples. Part Tracking uses edge recognition technology to locate a part in space and automatically crop/rotate the sample for processing of the found surface area. It increases system throughput by reducing setup time, improves run to run repeatability, and improves system to system and user to user reproducibility. It has all the Shadow Moire tools as standard.