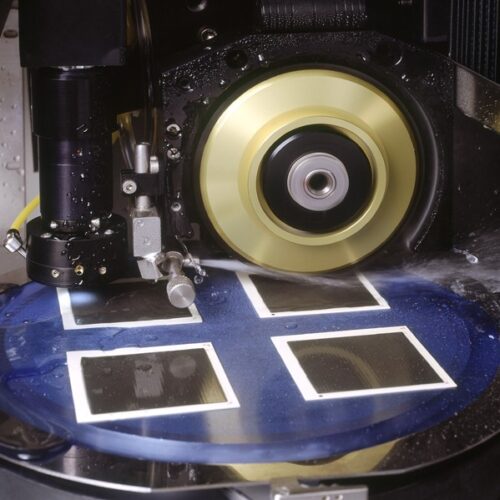

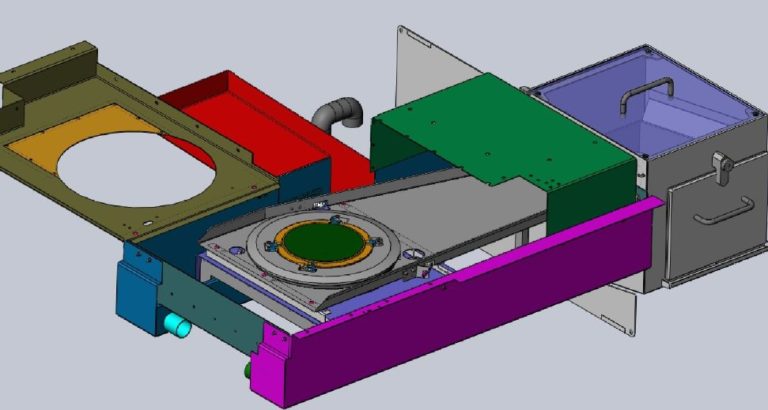

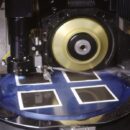

As part of the growing market of the LED segment and the ongoing demand to lower the cost of production per unit (CoO), ADT has responded with a dual spindle system model 7900 Duo that double the productivity while maintaining the same current production floor space.

The 7900 Duo system provides a perfect solution for applications that require a long cut cycle time such as image sensors and saw devices.

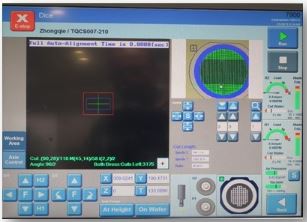

Further to the automatic vision and easy New User Interface (NUI), ADT is offering a unique feature for processing and programming of broken wafers.

7900 Series Advantages:

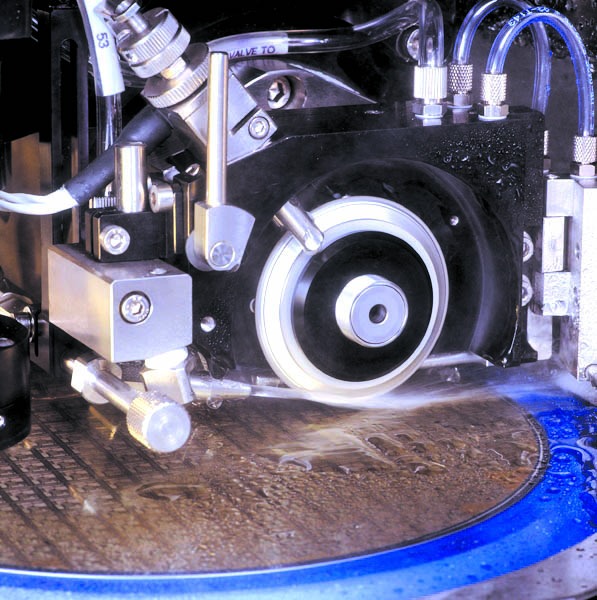

- Two facing spindles enable simultaneous dicing

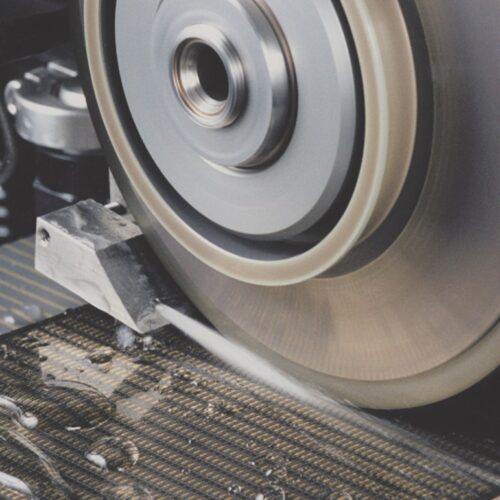

- Low vibration platform

- Fast automatic alignment and cut positioning increase throughput

- Small footprint reduces cost of ownership

- Automatic Kerf inspection increase yield

- Automatic Y offset correction ensures maximum precision

- Tape surface detection ensures consistent cut quality

- Touch screen user interface

Other key Features of Importance

- Highest Dicing Process Speeds – Lowest costs

- Air bearing feed axis (X)

- Fast automatic alignment and cut positioning for increased throughput

- Automatic Kerf inspection and quality analysis for maximum precision

- Process data logging and statistical analysis

- Fest & Simple Blade change

- SECS GEM platform ready

- Full access to any area of the system for easy maintenance access

- Small foot print