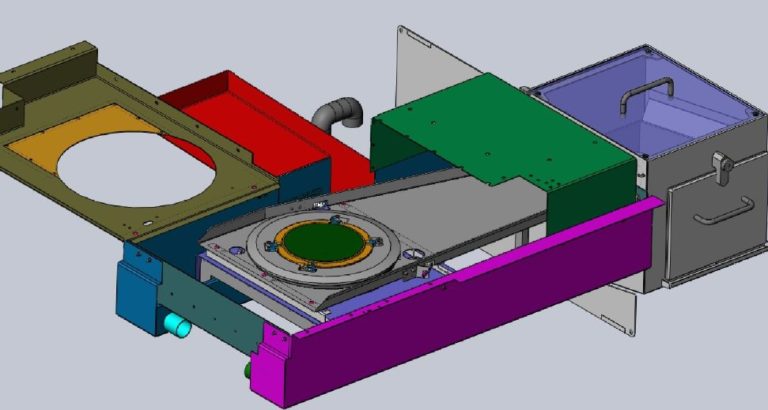

The 7120 / 7130 Series Dicing Systems offer a wide range of advanced automation and process monitoring options to meet the requirements of your most challenging dicing applications:

- Ceramic Substrates & Capacitors

- Glass

- Automotive Sensors

- PZT

- Glass on Silicon

- LED & LED on PCB Packages

- Package Singulation (BGA & QFN)

- Opto-electronic Components

- SAW Filters

- Sensors & MEMS

- LTCC

- IC Wafers

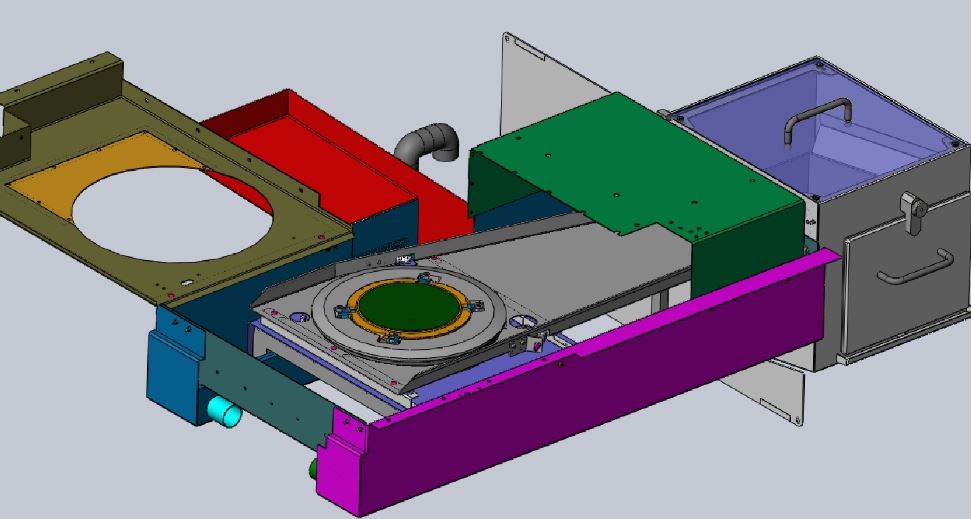

7120 / 7130 Series Features & Options:

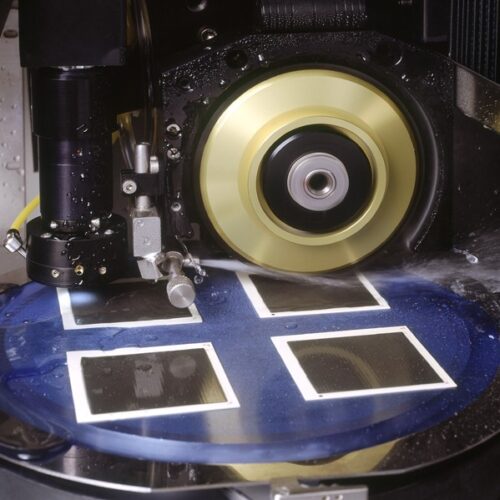

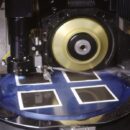

- Extra Large Area Dicing (7100 XLA)

- Large Area

- Tilting Spindle

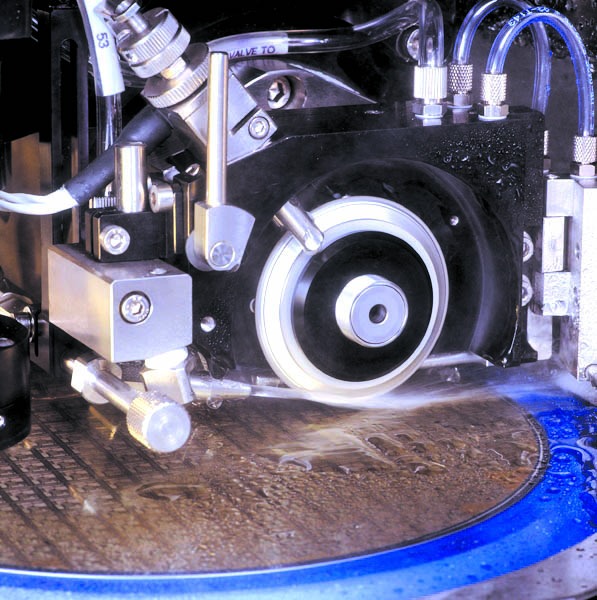

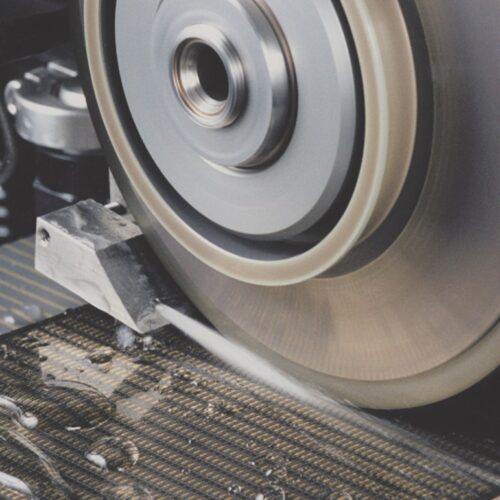

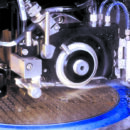

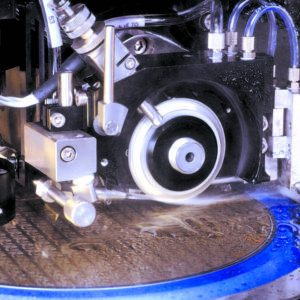

- Dressing Station for diamonds exposure and clogging prevention

7120 / 7130 Series Advantages

- 2” and 4” spindle dicing systems

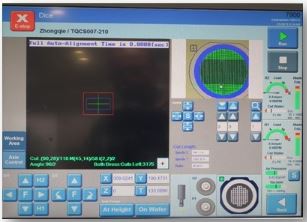

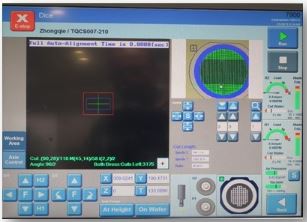

- A full range of automatic vision capabilities

- Advanced hardware platform for high reliability and low maintenance

- Heavy Duty, cast-iron base structure for superior precision and accuracy

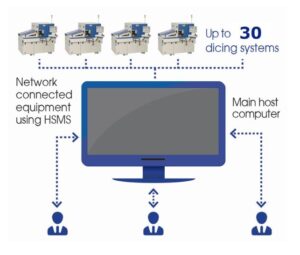

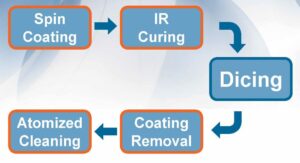

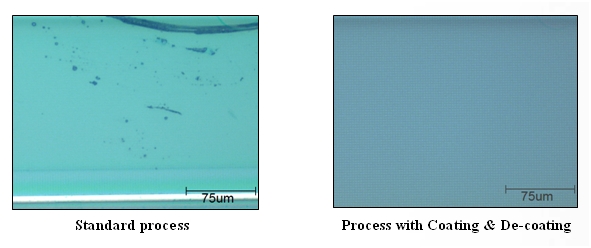

- Increased yield, throughput and process control

- Unique multi-panel processing capabilities

- Special blade wear forecast algorithm

- User-friendly software platform