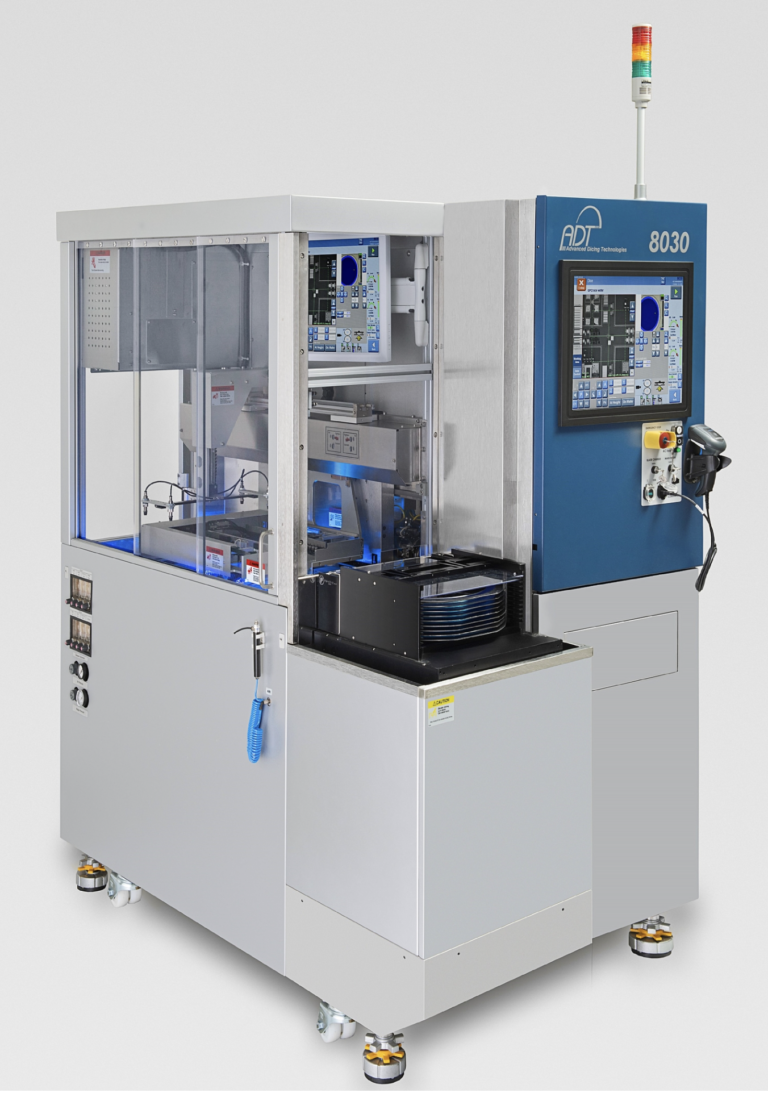

Ease of Use

The 8030 operates with the ADT intuitive New graphic User Interface (NUI), and includes two touch-screens: a 19” monitor for the main screen and a 17” monitor maintenance screen.

The maintenance screen assists with performing system setup procedures, blade change and some basic maintenance operations.

Leading Applications:

- Silicon wafers for Memory and Logic products

- MEMS (micro-electromechanical system)

- CMOS Image Sensors (CIS)

- Packaging (FOPLP, FOWLP, QFN, BGA)

Features and Benefits

- Bridge type frame

- Flexibility – Supports Hub and Hubless blades up to 3” O.D.

- Dual microscopes, fixed non-contact sensors and two dress stations

- Spindles of 1.8 KW or 2.2 KW high power (for challenging applications)

- Superior vision system with continuous zoom magnification

- Intuitive operation interface using a large 19” touch screen monitor

Other Key Features

- Highest dicing process speeds – Lowest cost

- Support up to 12” × 12” square products

- Industrial PC based on Win 10 OS

- Air bearing feed axis (X)

- Fast & Simple blade change with a spindle shaft lock mechanism

- Fast automatic alignment and cut positioning for increased throughput

- Automatic Kerf inspection and quality analysis for maximum precision

- Process data logging and statistical analysis

- SECS / GEM platform ready

- Load port ready for factory automation

- All electronic on top of the cut chamber