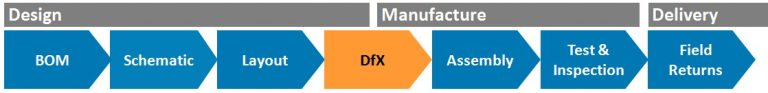

In order to deliver Defect Free Products, Accelonix is promoting a new concept of Design to Delivery flows, by applying the principles of Industry 4.0 as introduced by Aster Technologies: Enhanced Manufacturing Services 4.0 (EMS 4.0).

EMS 4.0 should be part of any electronics organization’s Continuous Improvement Program, to decrease product development time, production cost and manufacturing cycle-time, while increasing product quality, reliability and ultimately the customer satisfaction.

EMS 4.0 is articulated on two principles:

- Qualify the customer defect universe using traceability and repair loops (big data analysis). This universe includes not only manufacturing defects, but also design, and functional defects.

- Simulate the manufacturing flow from schematic or layout file in order to identify the possible consequences of inadequate testability and test coverage on a new design.

Traditional Workflow:

Longer, more expensive and obsolete.

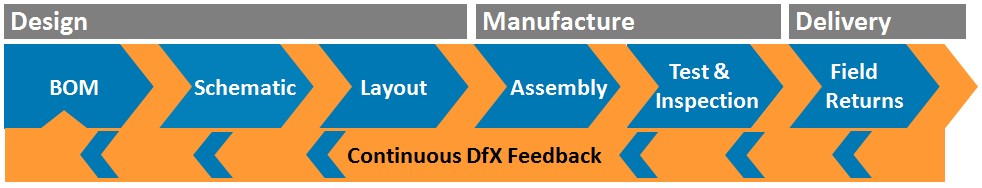

EMS 4.0 Workflow:

Improved decision-making, faster time-to-market, cheaper and better quality.

Lean design, Test and Manufacturing deliver Defect-Free products at lower cost!

ASTER has designed a complete digital software suite including TestWay and QUAD: TestWay flow for Design to Delivery and QUAD traceability for continuous DfX feedback.

Take a look at the Aster software toolsuite for EMS 4.0: