Precision

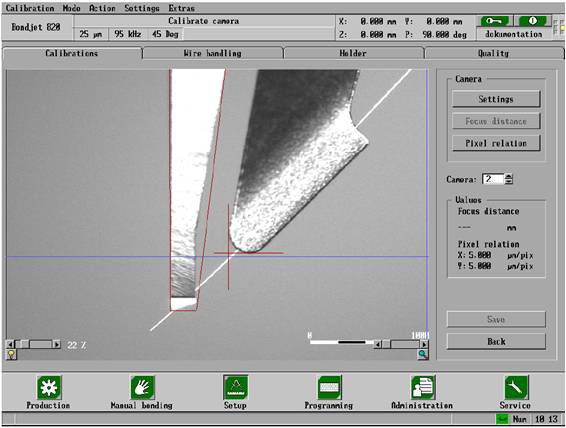

- High precision touchdown detection without time delay

- Precise bondforce control (static and dynamic)

Flexibility

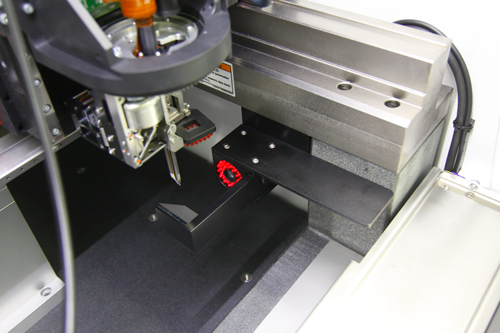

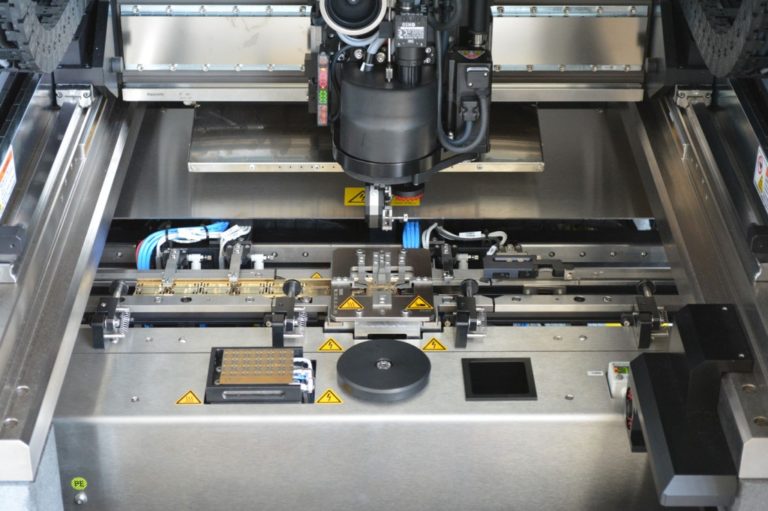

- Largest working area: 305 mm x 410 mm (12″ x 16″)

- Can serve two or more smaller bonding stations for efficient handling of smaller products or substrates,

- elimination indexing time and maximization of throughput (with indexers as well as manual loading)

- Universal software interface for indexer control

- Enables intelligent automation of extra large products

Speed

- Up to 7 wires per second, application-dependent,

- e.g. with parameters25 µm wire, 1 mm loop length, metallized wafer, 127 ms per bond;

- 2 mm loop length, 134 ms per bond

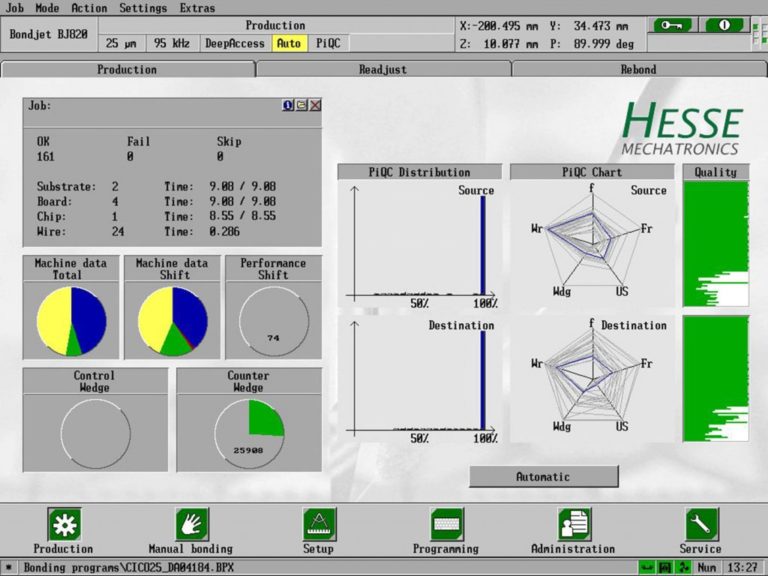

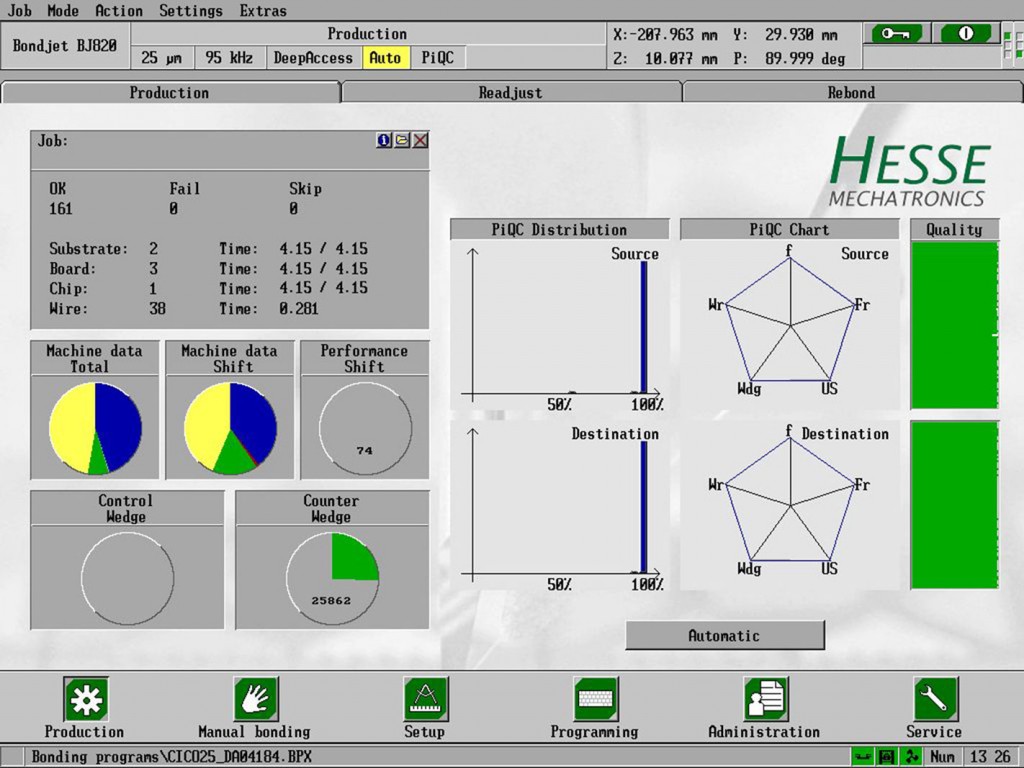

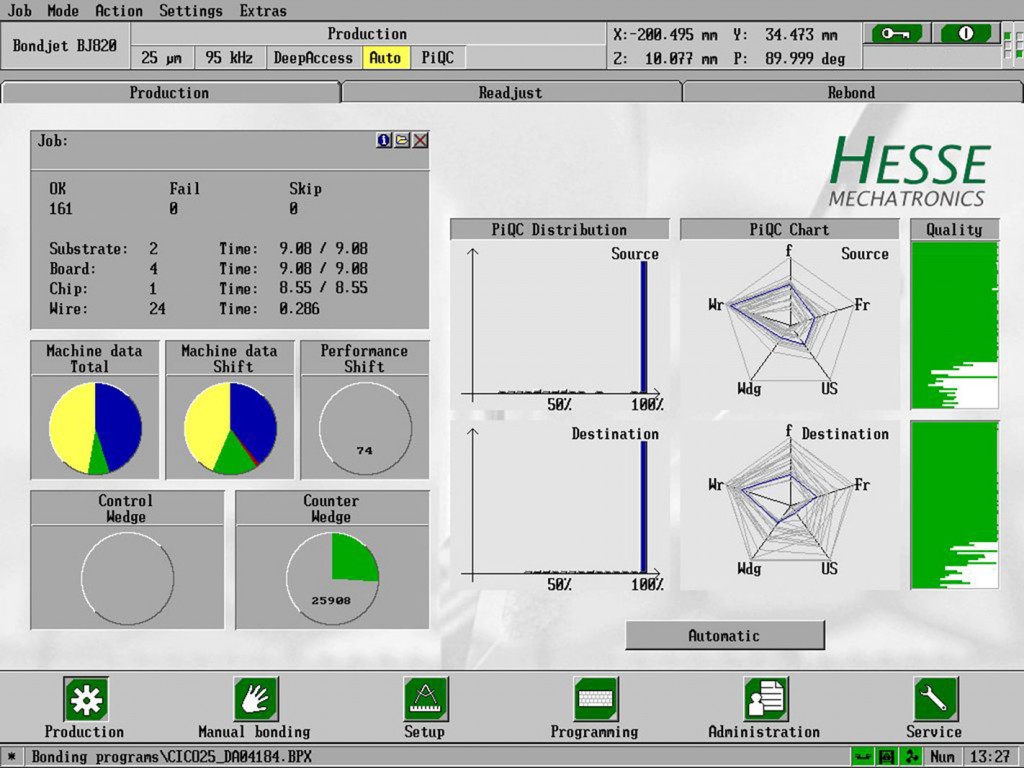

Quality

- Continuous real time monitoring of wire deformation, transducer current, frequency and impedance within programmable control limits

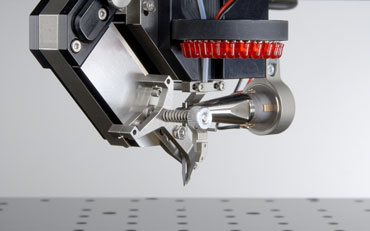

- Piezo bondhead with low maintenance

- Easy connectivity to Hesse Mechatronics` workbench with modules such as process data and backup system PBS200, PiQC, processdatadrain, Secs/Gem or to standard/custom MES (Manufacturing execution systems)

- Process integrated Quality Control (PiQC), detection of other parameters by additional sensors (e.g. friction) for 100% quality monitoring in real time (patented)

- E-Box: patented solution for optimized tool change and programmable alignment marks for wedge and wire clamp

Process Advantages

- Loop length: 70 µm up to 20 mm (2.8 mil – 800 mil), depending on wire diameter

- Various loop form functionsConstant wire length

- Constant loop height

- Individual loop shapes

- Fine Pitch 40 µm inline, 25 µm staggered/dual line (depending on wire and loop)