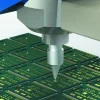

Desktop application robot with PC controlled vision software

- Position correction can be performed with vision in a variety of conditions, including previously undetectable components

- Link with dispenser Synchro SpeedTM function. Line width can be kept stable regardless of robot speed

- High quality dispensing can be performed automatically without complicated settings

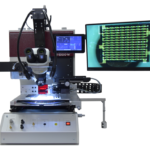

- Full 3D alignment

- Also available with clean room option

Equipped with high-precision full function correcting!

- By 3D alignment function, it is correspondence for XYθ revision to inclination of work and Z revision that we put together to undulate. It is most suitable for adhesive process of smartphone.

- Carry out production cycles from work import to export automatically and watch, and, also, is automatic in production information; is logging for database. Traceability correspondence by production log.

- Even if shape changes by misses, the new development edge detection function deployment, alignment object recognize alignment exactly.

- We display the application preview function deployment, application image.

- Labor saving, person by simple setup-saving.

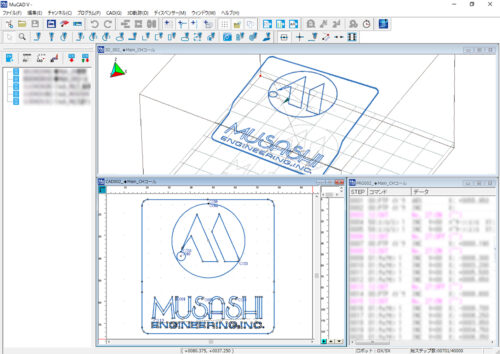

- Figure edites application program on PC by application pattern editing software MuCADV.