Standard and customized tools and consumables

Manual or semi-automatic die assembly processes always require a specific tooling set. The selection of a suitable tool is a matter of experience and knowhow.

For customized tools, you have to specify the chip dimensions X, Y and thickness, the quantity of bumps, the chip presentation and the bonding process. If the chip has solder balls we need the number and distribution on the chip and how the chip is presented.

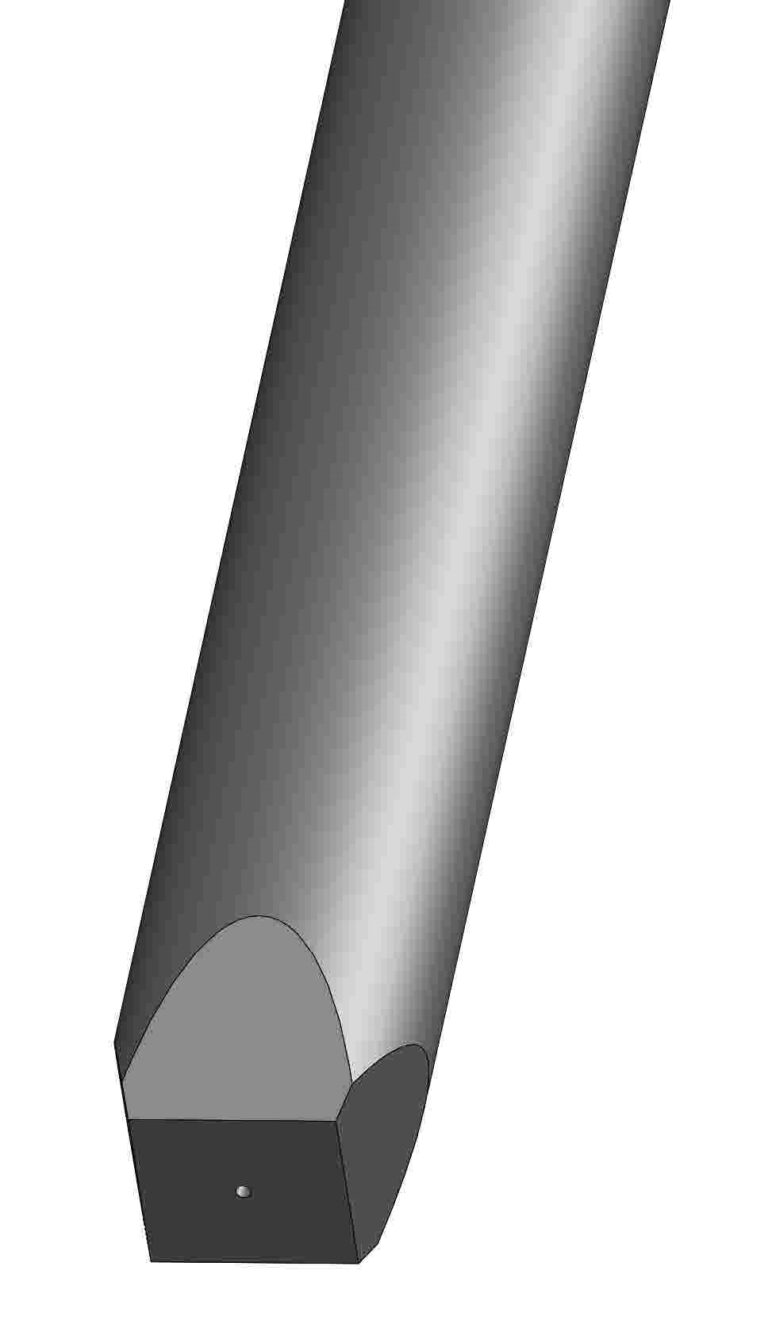

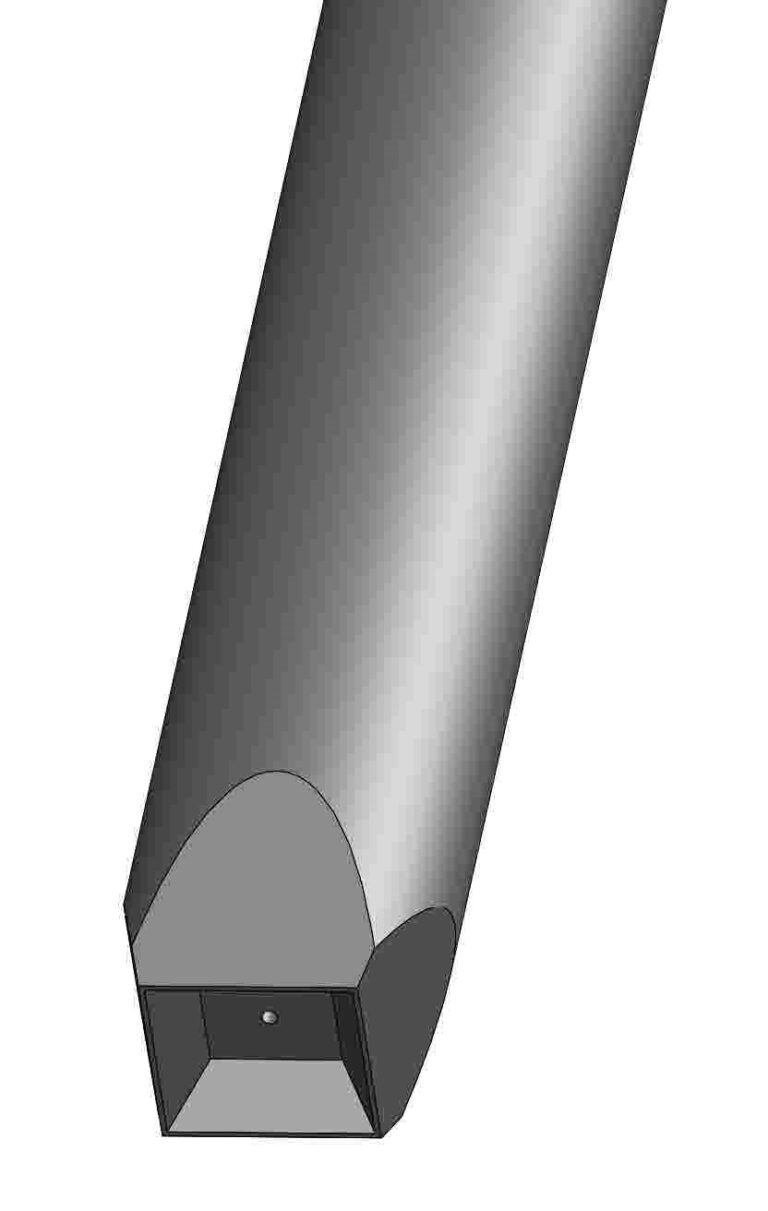

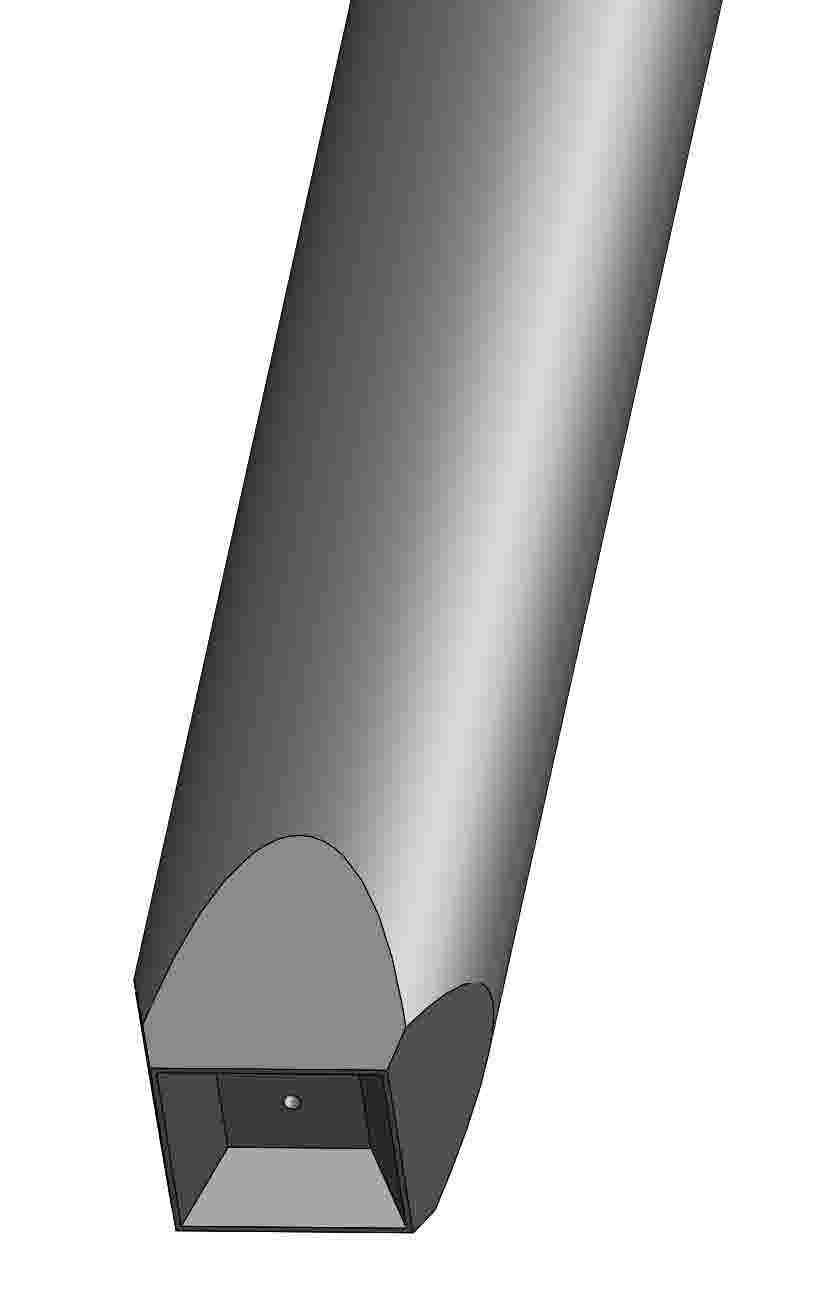

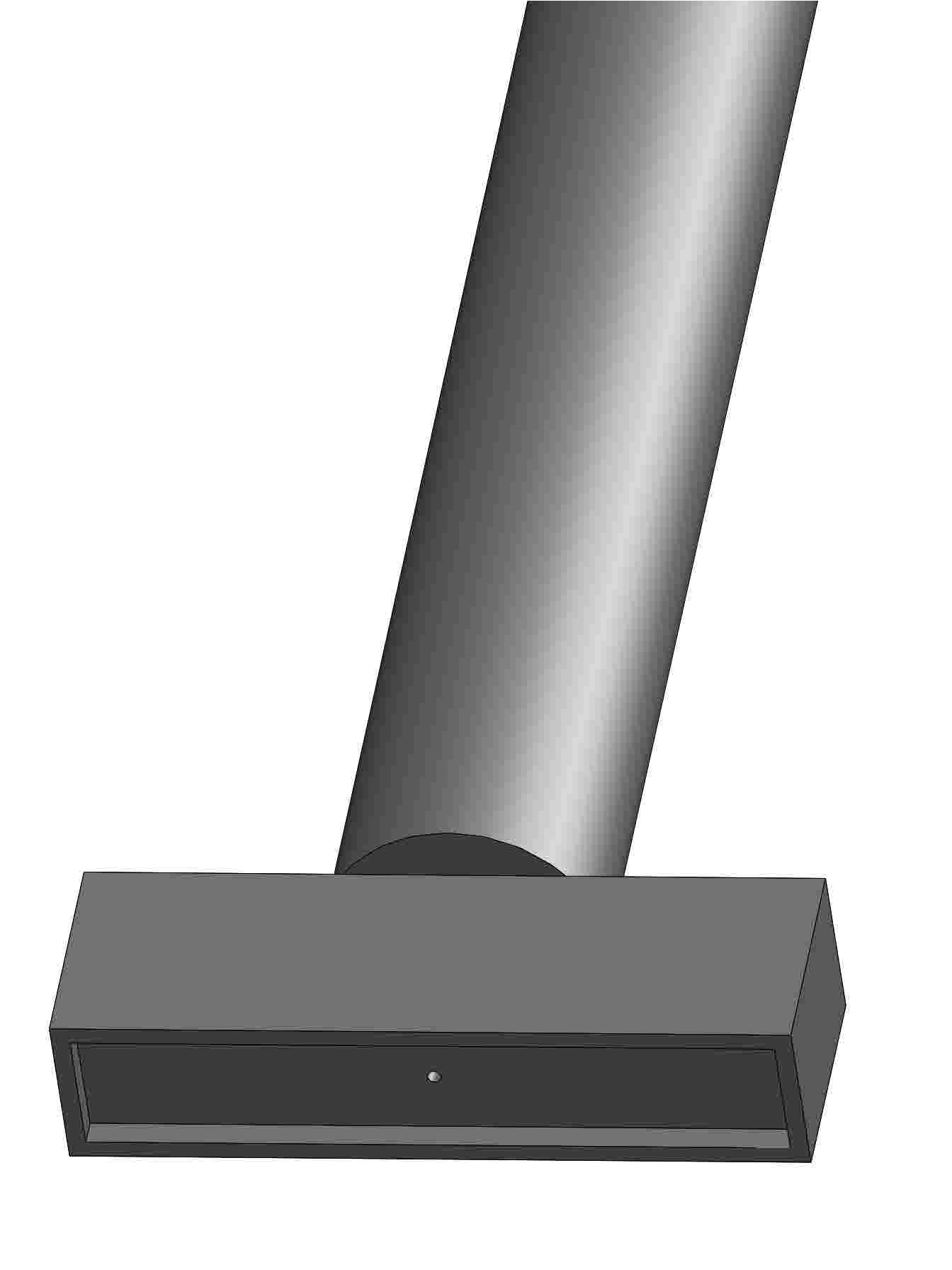

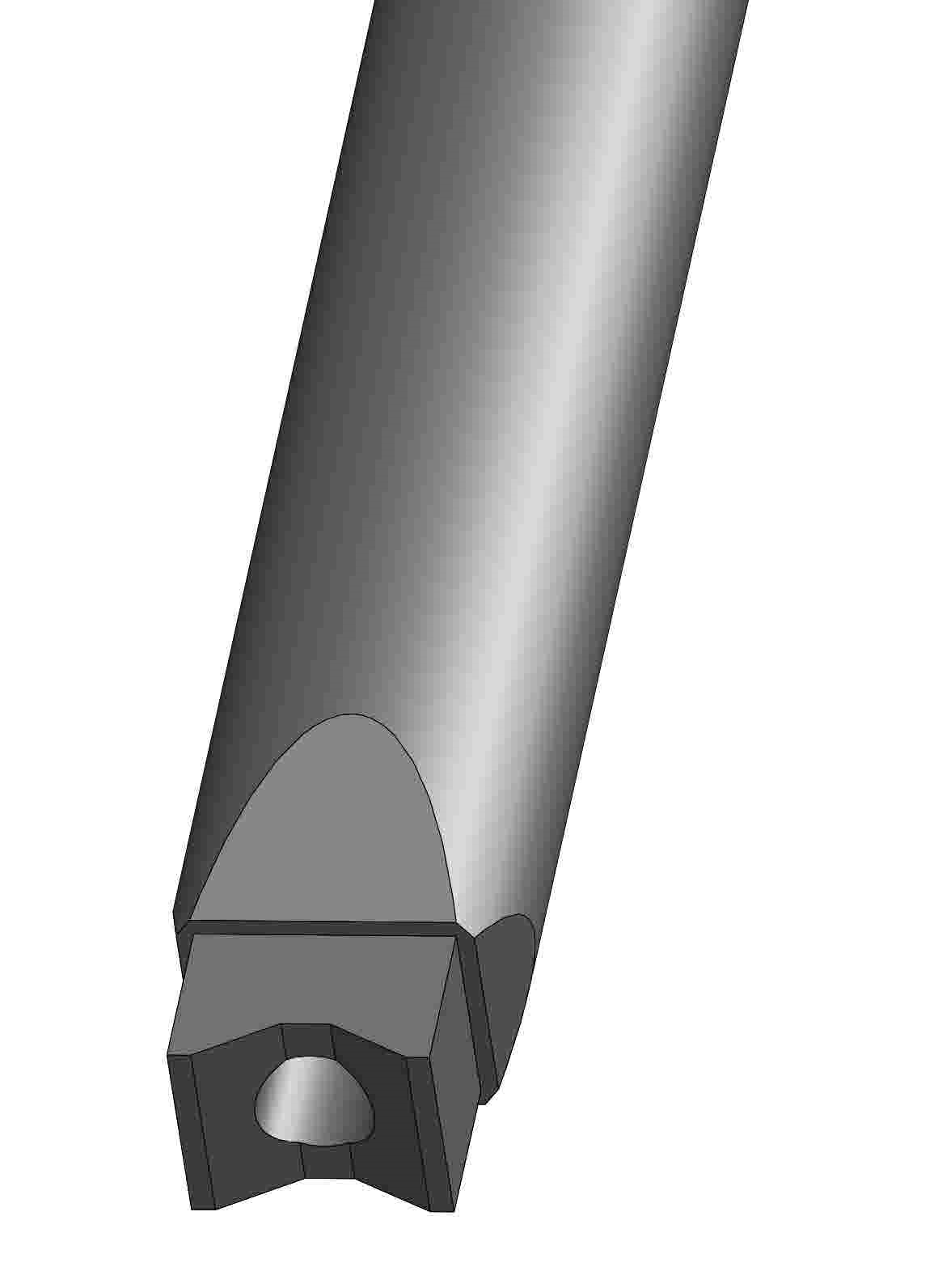

Tresky Standard Shanks:

For manual or semi-automatic machines – (T-3x0x, T-490x) Ø 3.000 mm / L: 25 mm

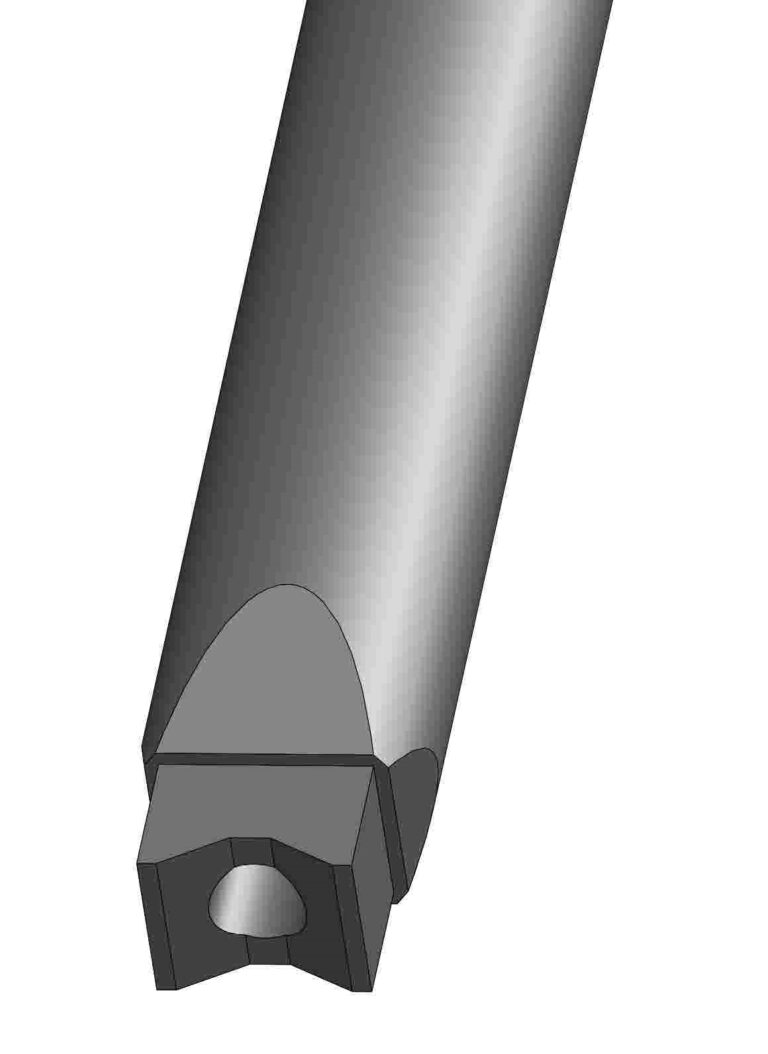

Special:

For ultrasonic spindle – Ø 3.175 mm / L: 30 mm

| Name: | Materials: | Properties: | Work temp. |

|---|---|---|---|

| HM | hard metal (tungsten carbide) | a long life thermal conduction | max. 500°C |

| SK | duroplastmaterial (vespel® polyimide) | for sensitive surfaces | max. 250°C |

| G | silicone | an alternative to other harder rubber materials | max. 200°C |

Other materials on request.

Part No. – Tools

| Outer diam. in mm | Vespel® tip | Tungsten carbide | Silcone tip | |||

|---|---|---|---|---|---|---|

| Ø 0.200 | 40.0513 | SK 0.2 | 30.1516 | HM 0.2 | ||

| Ø 0.250 | 40.0524 | SK 0.25 | 30.1506 | HM 0.25 | ||

| Ø 0.300 | 40.0500 | SK 0.3 | 30.1507 | HM 0.3 | ||

| Ø 0.400 | 40.0501 | SK 0.4 | 30.1521 | HM 0.4 | ||

| Ø 0.600 | 40.0502 | SK 0.6 | 30.1508 | HM 0.6 | ||

| Ø 0.800 | 40.0503 | SK 0.8 | 30.1509 | HM 0.8 | ||

| Ø 1.000 | 40.0504 | SK 1.0 | 30.1510 | HM 1.0 | 40.4011 | G 1.0 |

| Ø 1.200 | 40.0505 | SK 1.2 | 30.4585 | HM 1.2 | ||

| Ø 1.600 | 40.0506 | SK 1.6 | 30.4586 | HM 1.6 | ||

| Ø 2.000 | 40.0507 | SK 2.0 | 30.4587 | HM 2.0 | 40.4012 | G 2.0 |

| Ø 3.000 | 40.0508 | SK 3.0 | 30.4588 | HM 3.0 | 40.4013 | G 3.0 |

| Ø 4.000 | 40.0509 | SK 4.0 | 30.5101 | HM 4.0 | 40.4014 | G 4.0 |

| Ø 6.000 | 40.0554 | SK 6.0 | 30.5102 | HM 6.0 | ||