Large and small electronics manufacturers continuously need to reduce cost and improve quality. To meet these demands, Goepel electronic has launched two new Automatic Optical Inspection systems. The 3D XE series of AOI platforms combine low investment with full 3D inspection functionality.

The series consists of the stand-alone system Basic line · 3D XE and the inline system Advanced line · 3D XE.

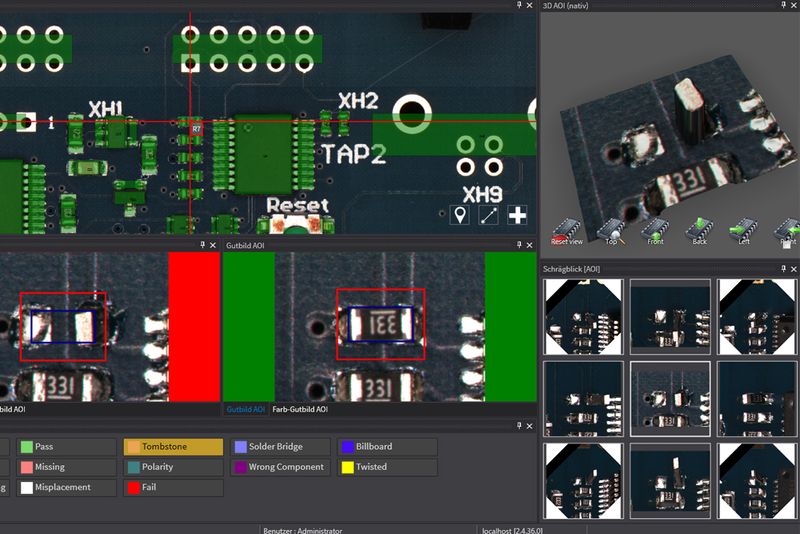

3D XE series AOI machines are controlled using the latest Pilot AOI software and MagicClick for AI-based, fully automatic creation and optimization of inspection programs.

This functionality enables the user to inspect new assemblies within a few minutes and without any component library, especially important for manufacturing service providers with a high mix of products. This makes 3D AOI very cost-effective even for the smallest board quantities and saves up to 80 % time for program creation and optimization.

For smaller production volumes, the offline 3D AOI system with manual loading is an great solution. The inline system provides flexible industry 4.0 communication interfaces, such as Hermes or Pulse, to allow total production line integration.

In addition, both AOI systems can be used as full 3D solder paste inspection systems (SPI). Thus, configuration as an inspection island offers a highly efficient and flexible production environment – especially for the Advanced line · 3D XE – for smaller companies with discrete production processes.

Goepel electronic‘s 3D AOI systems, developed and manufactured in Germany, feature innovative hardware and software components with a very user-friendly operating concept.

They provide a cost-effective investment and are highly efficient in production operation.

This opens the door for smaller electronic manufacturers to use the latest fully-fledged 3D-AOI technology and replace the outdated 2D systems.

Contact us now to review your inspection needs and get an offer for your personalized solution.