Replacing critical devices in e.g. medical imaging, process automation, robotic manufacturing, etc. can be very costly. Therefore repairing the equipment is often the preferred solution and defect printed circuit boards assemblies (PCBAs) are more often repaired rather than replaced.

All electronics are bound to fail, sooner or later. In contrast to production faults, these field faults are most likely problems caused by physical damage from stress in the outside world. Damage from being dropped, voltage surges (lightning!), excessive heat and user abuse are common issues. But in some cases it can be a failed component that has degraded over time, such as an electrolytic capacitor.

So when looking for damaged components it is good practice to start with components that have a higher fatality rate such as these electrolytic capacitors. From there, work your way down from the most complex parts (ICs and semiconductors) to simpler parts (resistors and capacitors). The more complex the PCB, the more time is required to find the faults. At this step in the troubleshooting process an instrument that can help you to quickly detect this damage is essential!

Since more than 40 years, Huntron has been developing a range of test instrumentation specifically designed for component level troubleshooting on PCBAs in rework, repair, and remanufacturing. The Huntron Trackers utilizes the power-off testing methodology of Tracker Signature Analysis.

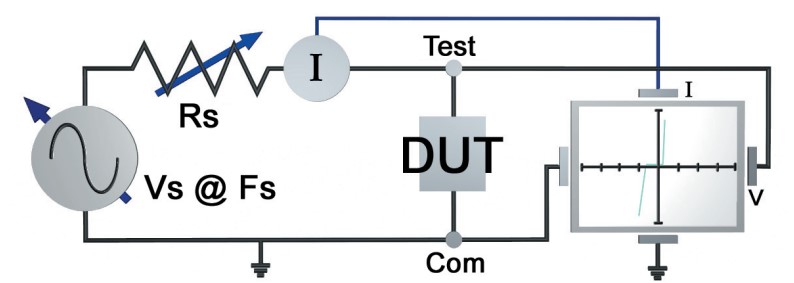

A current-limited AC signal is applied across two points of an electronic component or circuit. The resulting current/voltage waveform is presented on a display using vertical deflection for current and horizontal deflection for voltage providing a unique signature that represents the overall “health” of the DUT (device under test).

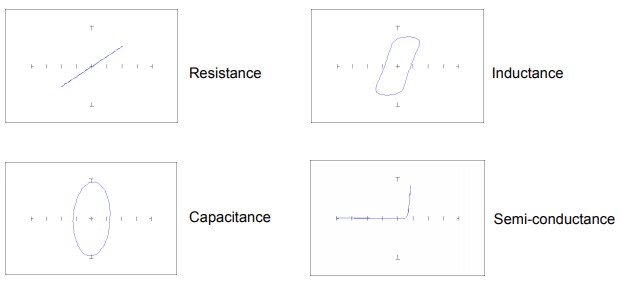

Tracker signatures can be categorized based on the four basic component types.

These signatures are resistive, capacitive, inductive and semiconductive signatures. All signatures will exhibit at least one of these characteristics but more often include combinations that are referred to as composite signatures.

By comparing Tracker signatures from a working circuit board to the signatures of a non-working board, good versus bad, you can troubleshoot down to the component level.

Additionally troubleshooting with Tracker signatures is possible even without the use of documentation or known good circuit boards.

This is accomplished by searching for patterns in the signatures that are displayed on like pins of a component or bus.

Huntron Trackers allow to quickly locate problems with digital IC protection circuitry by comparing similar pins and effectively search for component failures regardless of the overall board function.

The Benefits of Power Off Testing:

• Test Circuit Boards that cannot be powered on

• Comparison troubleshooting that makes schematics or documentation unnecessary

• Power-off Circuit Board Test can Reduce risk to the PCB from further damage if powered up

• Screen PCBs for catastrophic problems before adding power

To learn more about using a Huntron Tracker and analog signature analysis for circuit board testing, contact us to receive the “Fundamentals of Analog Signature Analysis” white paper!

More information on the Huntron Trackers can be found on our Huntron productpage.