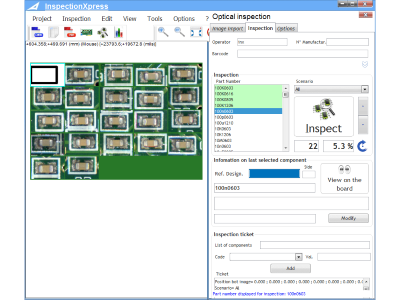

Inspection Xpress is a powerful solution for the inspection of the first off board from a new manufacturing set up. Additional use includes the visual inspection of prototypes, small-series production, sampling and Final Inspection.

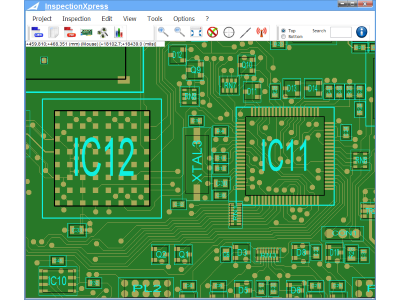

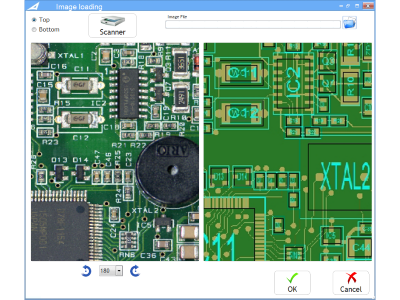

Based on a captured image of the PCBA (scanned image, photograph,…), combined with a unique and innovative way of representing the component images, Inspection Xpress assures a 100% visual inspection of all components in an extremely fast way.

The software optimizes and manages the human, visual inspection for prototype and low volume production.

Most important,Inspection Xpress improves quality assurance and at the same time limits the downtime of the production line, awaiting approval of the first article.