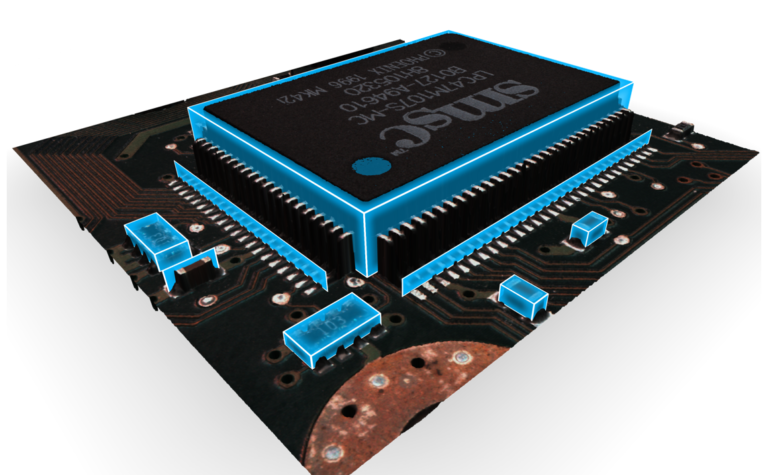

Stand-alone AOI System for manual Loading and flexible Adaptation of different Assemblies.

The BasicLine can be utilized as a production AOI system or as separate repair station and is characterized by a comfortable fault classification via keyboard.

A multitude of variants and settings in illumination and camera make the system a highly precise and fast inspection device. Customized configurations and technical upgrades are also possible.

Stand-alone AOI System for manual Loading and flexible Adaptation of different Assemblies.

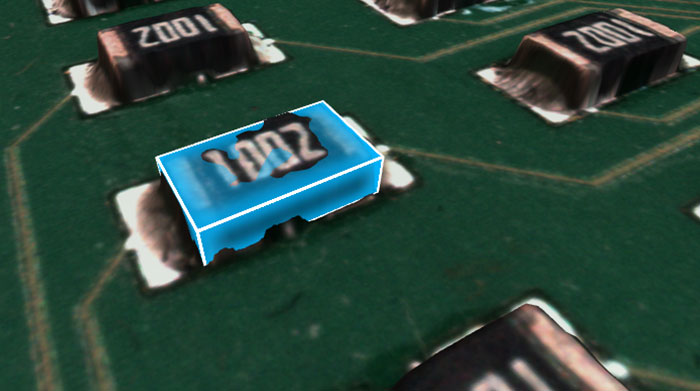

- Pixel adapted camera module for all system variants

- Telecentric lens for parallax-free image capturing

- Multi-directional image capturing by means of 360° angled-view module rotation

The AOI system features Goepel MagicClick for fast automated programming and integrates to Goepel PILOT CONNECT for integration with MES and database systems to centralize all inspection and machine data..