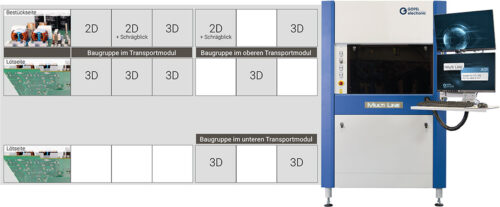

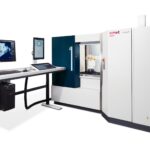

The Multi Line AOI is an AOI system for the inspection of components and solder joints in a single system, without flipping the PCBA.

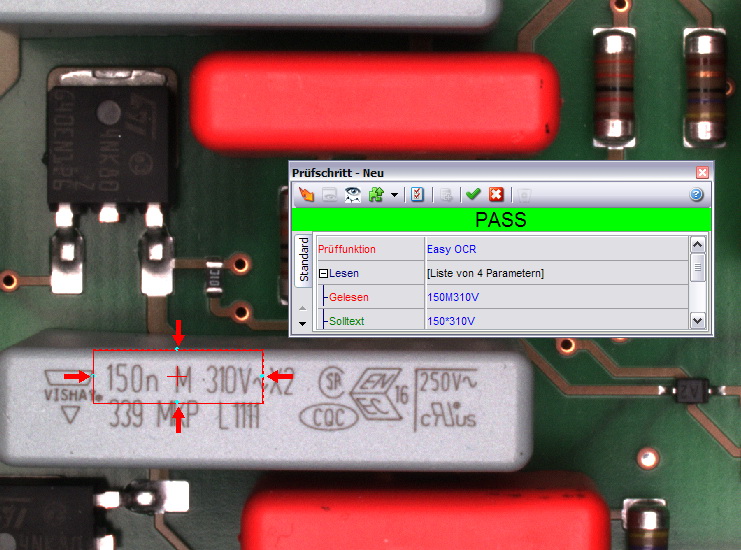

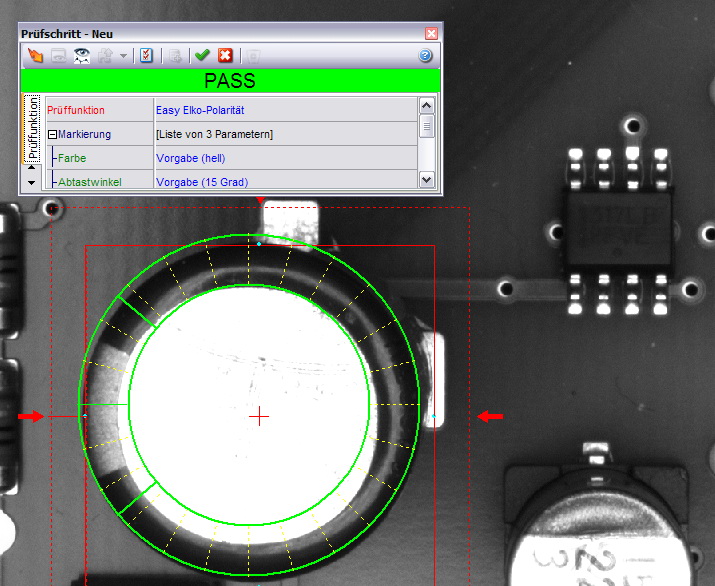

With up to 8 angled view cameras, concealed components and lateral markings can also be inspected. The inline system inspects THT and/or SMD components from the top.

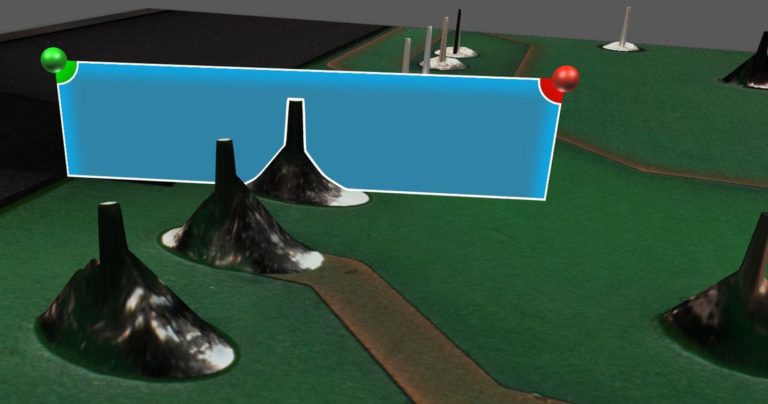

A 3D camera module below the conveyor belt simultaneously and independently performs a 3D inspection of the bottom components, solder joints and THT pins.

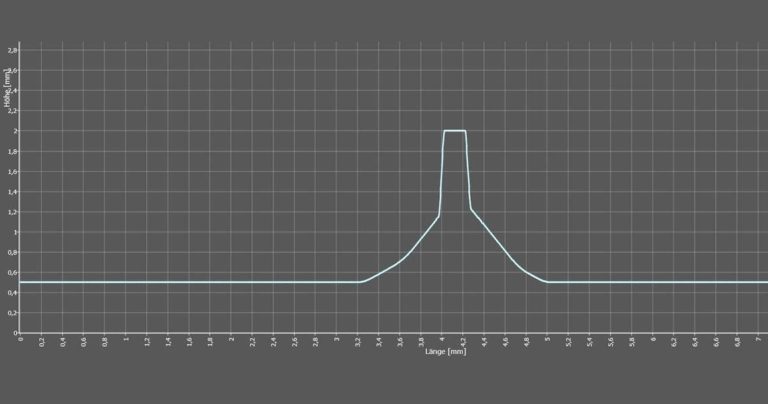

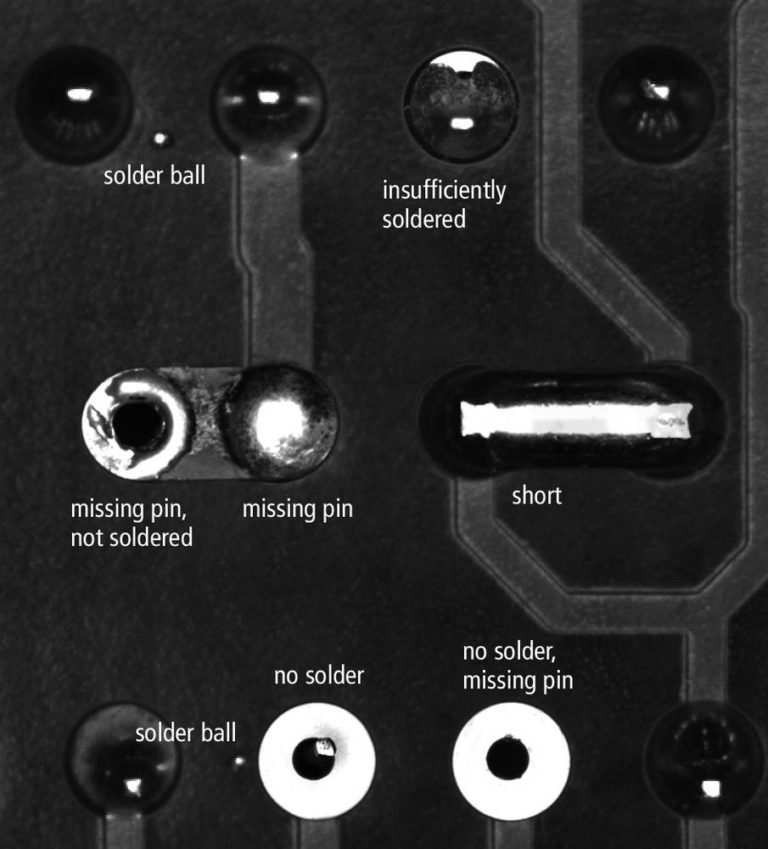

Components, solder volume, solder flow and pin height are precisely measured and defects reliably detected.

The automatic or manual feeding of assemblies can also handle workpiece carriers. Thanks to a height-adjustable camera module, the Multi Line AOI allows a component clearance of up to 110 mm in 3D configuration.

The AOI system features Goepel PILOT AOI user software and integrates to Goepel PILOT CONNECT for integration with MES and database systems to centralize all inspection and machine data.