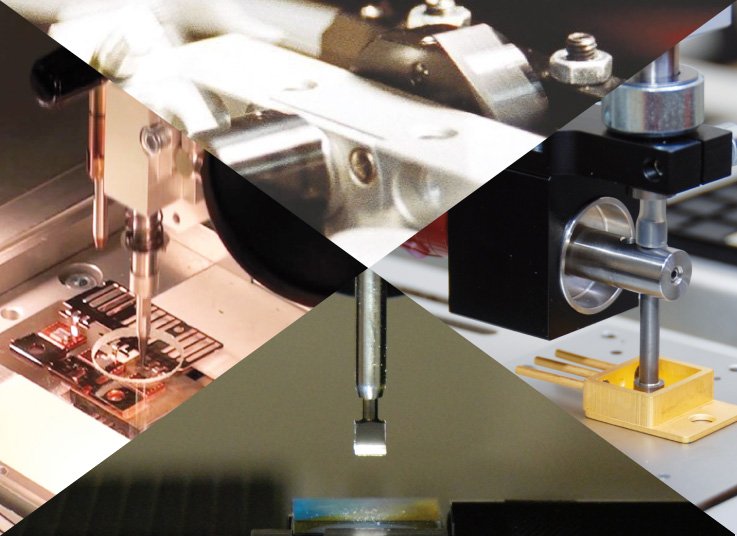

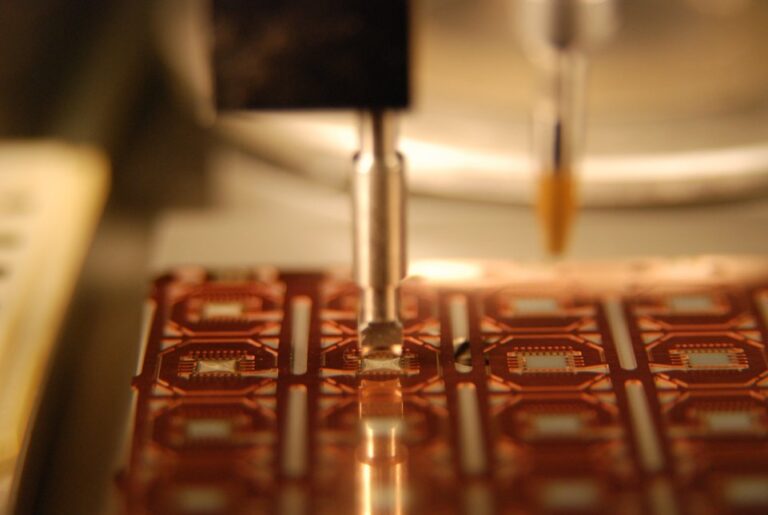

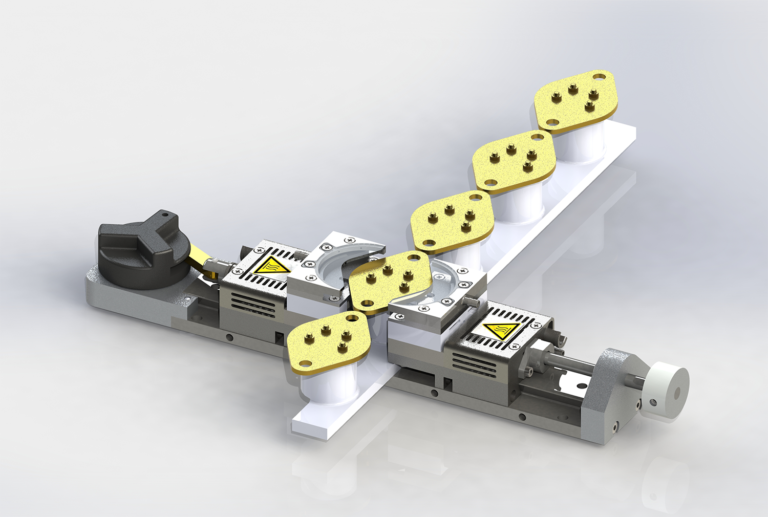

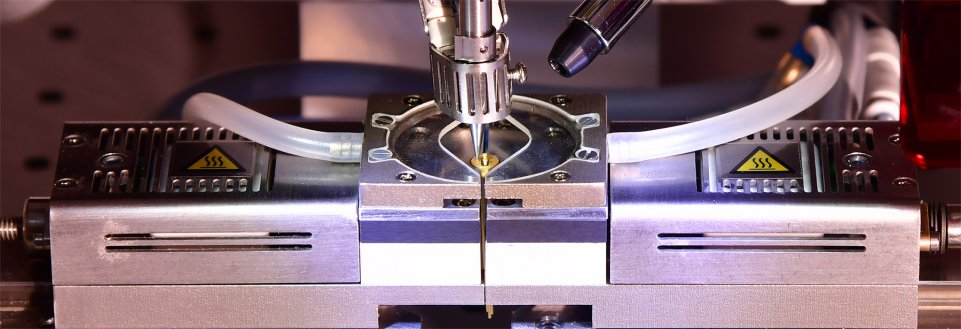

Stamping and fluxing unit

Suitable for stamping of adhesive or for dipping of picked-up Flip-Chip (or any other component) into Flux before placement.

Both processes use the same motorised adhesive/flux container. The motorised container is maintaining a defined and constant layer of flux or adhesive. For stamping of adhesives application, is the stamping tool, attached to the dispenser arm by means of an adapter.

All Tresky Die Bonder can be equipped with a stamping and flux station.

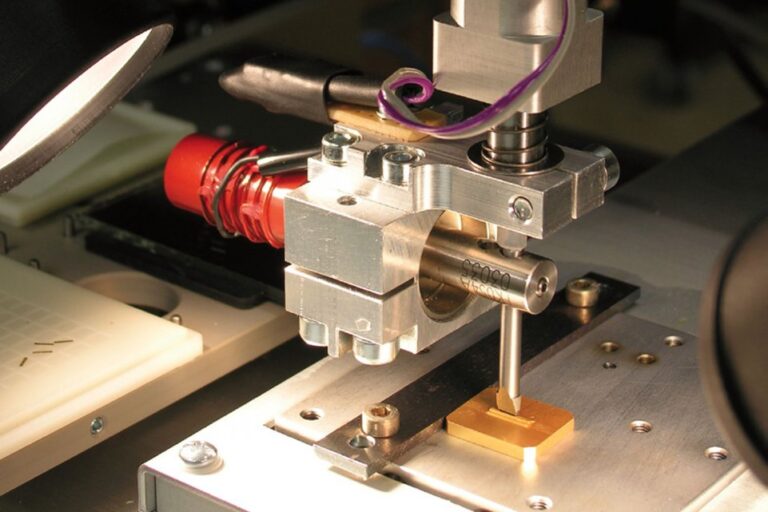

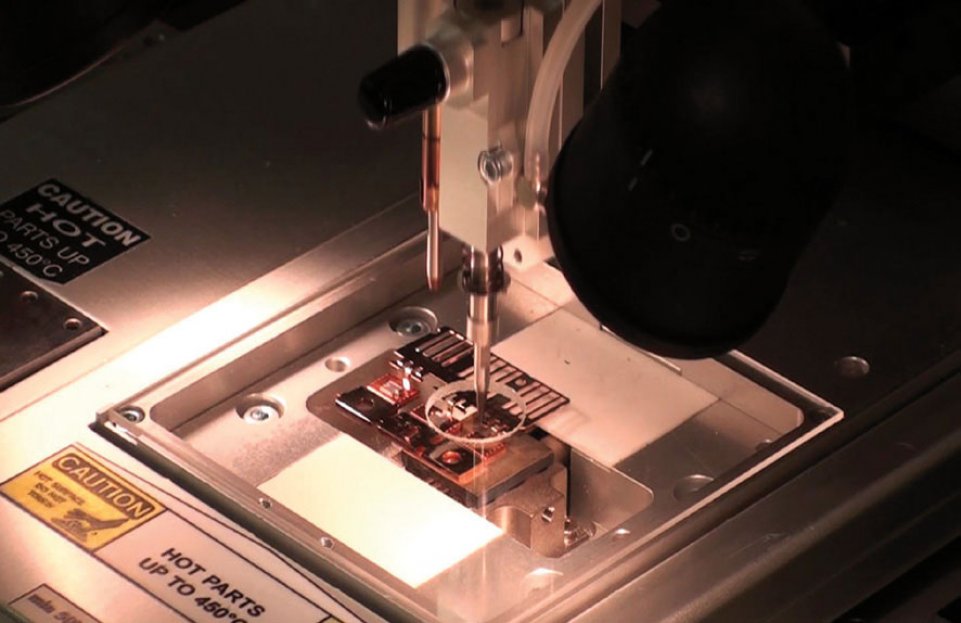

Ultrasonic head

The ultrasonic unit extends the range of application of Dr. Tresky AG Chip Bonders to include thermal and ultrasonic applications. The digital generators have an adjustable power up to 40W or for higher demands up to 100W at a frequency of 90kHz. The ultrasonic transducer is mounted on the rotating spindle with a few hand movements, which guarantees a flexible use.

All Dr. Tresky machines can be equipped with an ultrasonic unit.

UV Curing

The UV curing unit is designed for fast UV adhesive curing during the bonding process on the Chip Bonder machine. A high-end light source and the automatic cover of the dispensing needle are included with this option. The field of application is wide and includes both micro-component and optical component connections such as glass fibres, VCSELs and photodiodes.

All Tresky machines can be equipped with a UV curing unit.

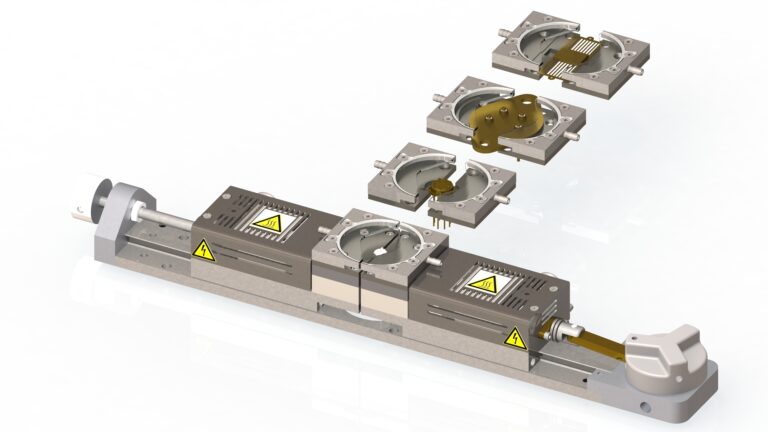

Eutectic

Many bonding processes in microelectronics require the supply of heat. That is why Dr. Tresky AG has developed a wide range of static and dynamic heaters and a powerful software package.

All Tresky Die Bonder can be equipped with the following options:

- Heating plates for static heating

- Heating plates for temperature profiles with cooling

- Tool heating for temperature profiles with cooling

- Software for graphical programming with real time display

- Inert gas chamber available for all heating plates

- 2nd spindle for pre-form handling

- Scrub or Ultrasonic

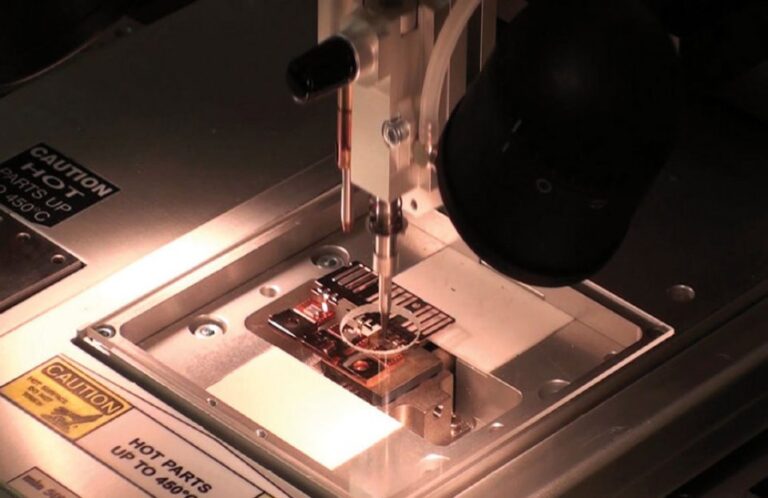

Dynamic TO-Heating Unit

Seeing increased demands on the market Tresky offers now the second generation of the dynamic TO-Heating Unit with excellent qualities.

- For TO sizes up to D30mm / pin lengths 24mm

- Heating ramp up to 40K/s

- Max. temperature 450°C

- Gas chamber and gasflow controller

- TO Indexer optionally available

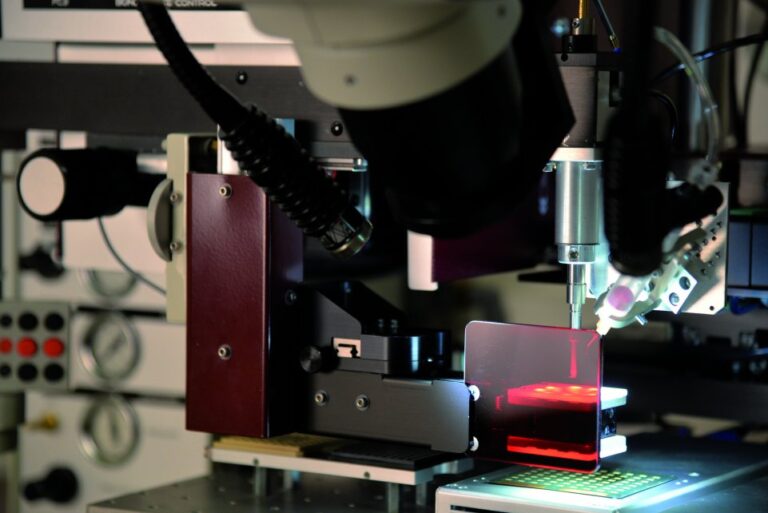

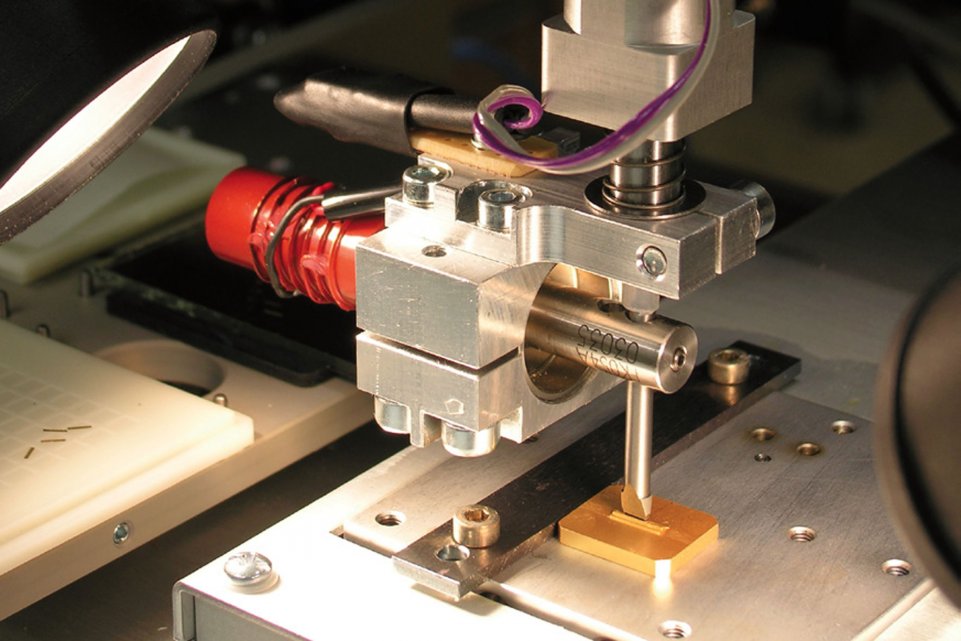

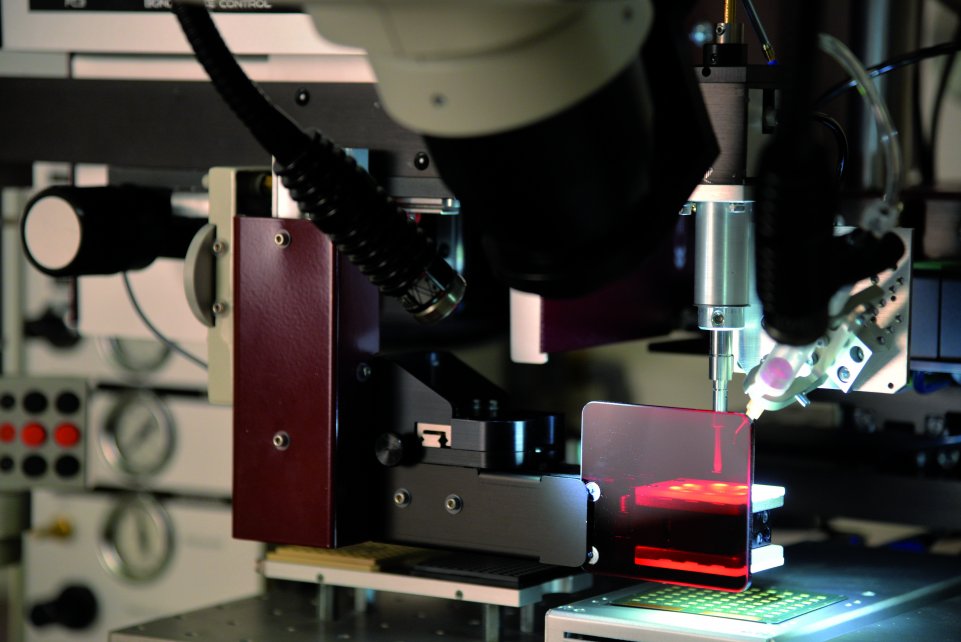

Flip-Chip Ultra camera

Tresky’s Flip-Chip Ultra module is a beam splitter optics, which allows the simultaneous viewing of two objects by an optical overlay (superposition) on the monitor.

The Flip-Chip optics has a built-in Ultra HD camera with digital magnification as well as integrated LED lights for optimal illumination of various substrates and components. In combination with the high magnification and the fine adjustment of the XY-Table Micro an accuracy of +- 1µm can be reached.

All Tresky Die Bonder can be equipped with a Flip-Chip Ultra option.

Technical Specification:

- 400x digital zoom Ultra HD camera

- Field of view 0.9mm x 1,2mm – 6,5mm x 4.8mm

- LED illumination (up, down and coax)

- Multipoint Alignment 30mm x 10mm

- XL Version with Multi Point Alignment up to 85mm x 50mm

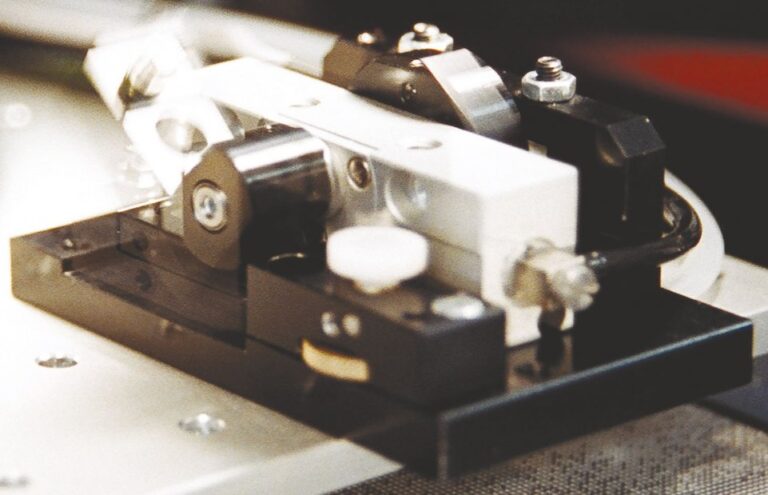

Flip station for Dies

The Tresky Die Flip-Station is designed to minimize the mechanical stress on the Chip to avoid any damage. The soft flipping of the Die upside down is gentle controlled and can be activated manual or automatic. An exchangeable tip and support plate allows to handle a wide range of Die sizes. The adjustable speed and height gives you the most possible flexibility to flip a Die.

It’s possible to flip any devices. Tool change is very simple.

All Tresky Die Bonder can be equipped with a Flip-Station.