A New Bonder for manual or automatic bonding

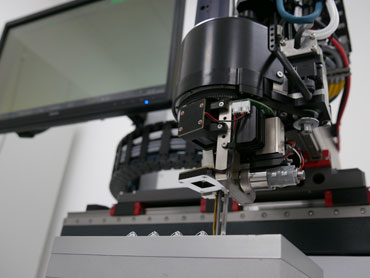

The Bondjet BJ653, with its changeable bond heads, serves the wire bonding processes of wedge-wedge as well as ball-wedge and can handle fine wire, heavy wire and ribbon.

The operating methods from manual to automatic bonding is particularly appropriate for the use in laboratories, in the development and for suppliers for validating their product quality. BJ653 is ideal for product samples, pre-production prototypes or small volume production runs in proven and reliable Hesse quality.

The Bondjet BJ653 is part of the new bonder generation and offers the same handling regarding operation and look & feel as the the fully automatic machines of Hesse.

It is characterized by an open workspace, which achieves the same process result as in a fully automated production wire bonder.

The Bondjet BJ653 has a lower throughput than the other Bondjets but is the avenue to fully automatic wire bonding.

The available bondheads for the BJ653 are identical to the bondheads for the Hesse production machines. This enables a targeted preparation of the production process on the Bondjet BJ653.

|

|

Features:

- Bondheads for all common wire materials

- Wear-free components with piezo technology

- Maintenance-free flexure hinges

- Intelligent bondhead connecting system with integrated memory storing all calibration data: bondheads are interchangeable within a few minutes

- Optimized pattern recognition

- Use of all common wire spools

Specifications:

- Open working area BJ653: X: 100 mm (3.9″); Y: 90 mm (3.5″); Z: 50 mm (2.0″)

- Bond head rotation: 440°

- Digital ultrasonic generator with PLL (Phase Locked Loop), internal frequency resolution <1 Hz; programmable ultrasonic power output

- Windows® Embedded operating system

- Height of operator desk: 730 mm (29″)

- Footprint: 1070 mm x 1020 mm x 1560 mm (42″ x 40″ x 61″) (W x D x H) incl. monitor

- Weight: approx. 325 kg, depending on configuration