Lithium-ion batteries (LIB) have become an indispensable part of modern life. The intensive testing of batteries is not only important for ensuring their quality and function but even more for safety aspects. CT can show you all details.

Lithium-ion batteries (LIB) have become an indispensable part of modern life. They are available for numerous applications such as smartphones, tablets, and notebooks, but their importance is rapidly increasing with regards to e-mobility and in the aerospace sector.

The intensive testing of batteries is not only important for ensuring their quality and function but even more for safety aspects. Declared as dangerous goods under the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR), for example, short circuits and even fires can occur due to faulty assembly or leaking housing.

The most effective inspection method for batteries is the non-destructive X-ray technology. It’s the only method that makes the inner structures visible through the housing, and even batteries already installed in devices can be examined safely and accurately without being removed or opened.

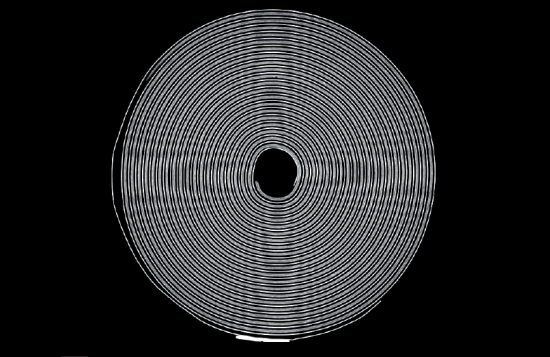

Many battery cell manufacturers and researchers have adopted industrial computed tomography (CT) to perform non-destructive testing (NDT) on the part to ensure quality throughout the R&D and production processes. A CT scan produces a 3D volumetric density map. The 3D-volume is generated by the reconstruction of a high number of 2D X-ray images. Many 2D projection images can be combined by powerful software to produce a 3D volume of practically any part, object, or product. With latest developments and complex designs of lithium-ion batteries, this is the only way to accurately get a non-destructive view of the inside of these parts.

While CT technology has taken its rightful place as a viable NDT tool, many engineers may not realize what an important role it can play in the discovery phase of research and development. Utilizing CT in R&D can avoid many issues later in the production process by identifying key information about part design, raw materials and how well it matches the intended geometry, all of which are vital to the success of the product. Once engineers discover the power that CT delivers as an informational tool rather than just a quality tool, they will never look at CT the same way again.

With this white paper, Comet Yxlon want to share the current capabilities of CT hardware and software for industrial applications. As with all good things, the information retrieved at the very beginning can help the engineers to be more agile and avoid costly downtime later in the design or production stages.