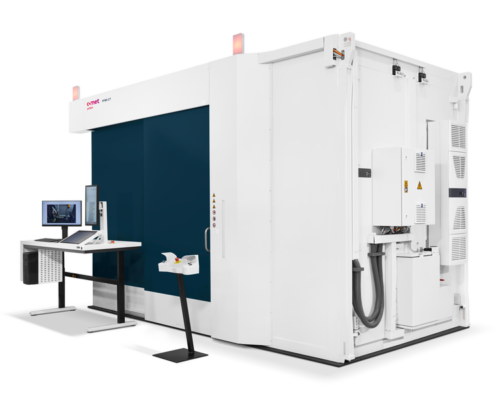

The FF85 CT with its dual-tube configuration, high energy and high resolution achieves extremely precise inspection results for a wide variety of material types and part sizes, such as:

- Aluminum, steel, and super alloy components

- Additively manufactured parts

- Battery cells, modules, and systems

- Fiber-reinforced composites

- Plastic injection molded parts

- Cultural assets, historical art, and archeological objects

- Geological, paleontological and biological samples

- Mechatronic modules

Small parts or large parts, the optional combination of two X-ray tubes with a spacious flat-panel detector (DDA – digital detector array) and a linear detector array (LDA) caters to the broadest application range. While the mini-focus tube, with its high energy of up to 600 kV, is the right solution for large and dense parts, the directional micro-focus tube (up to 300 kV) provides detailed insights into the inner structures of small components. Seamless switches between 2D radioscopy, 3D cone-beam, and fan-beam CT provide outstanding flexibility and the creation of individual inspection processes.

Comet Yxlon developed the CTScan 3 line detector array (LDA) for customers’ special requirements and challenging applications. With its unprecedented signal-to-noise ratio, its dynamic range, and a pixel pitch of 254 μm, it is the no-alternative solution for the crystal-clear inspection of large and/or dense components. It is designed for up to 600 kV operation reducing unwanted scatter radiation and providing low-noise electronics and highly efficient scintillators.

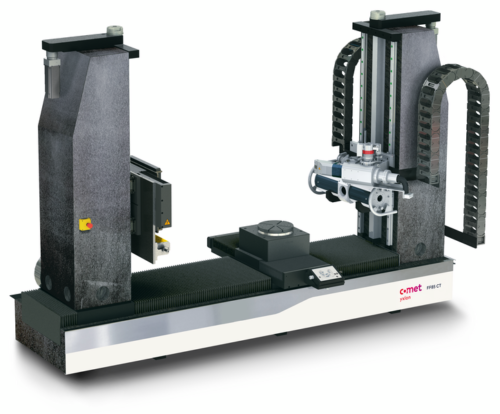

Another building block that contributes to the premium performance of FF85 CT is the rock-solid granite-based manipulator. It makes the system extremely precise and durable by providing warp resistance and temperature stability.

Graphic symbols and a wide range of automated functions, displayed on the intuitive user interface Geminy make operation easy – regardless of the operator’s skill level. At the same time, it offers a great number of features for flexibility regarding part sizes and inspection tasks, like CT trajectories such as HeliExtend (helical CT scan and reconstruction method), horizontal and vertical field-of-view extensions, a virtual rotation axis, and standard quick/quality scans. Image enhancement tools like ScatterFix 2.0, beam hardening reduction (BHC), or metal artifact reduction (MAR) reduce or eliminate scattered radiation or artifacts in the image.

A system health monitor gives you information on various parameters. Results are consolidated and displayed in a ‘traffic light’ representation. Additionally, you can access this health-state of the system and the progress of the CT (and reconstruction) from your office through our remote monitoring software.