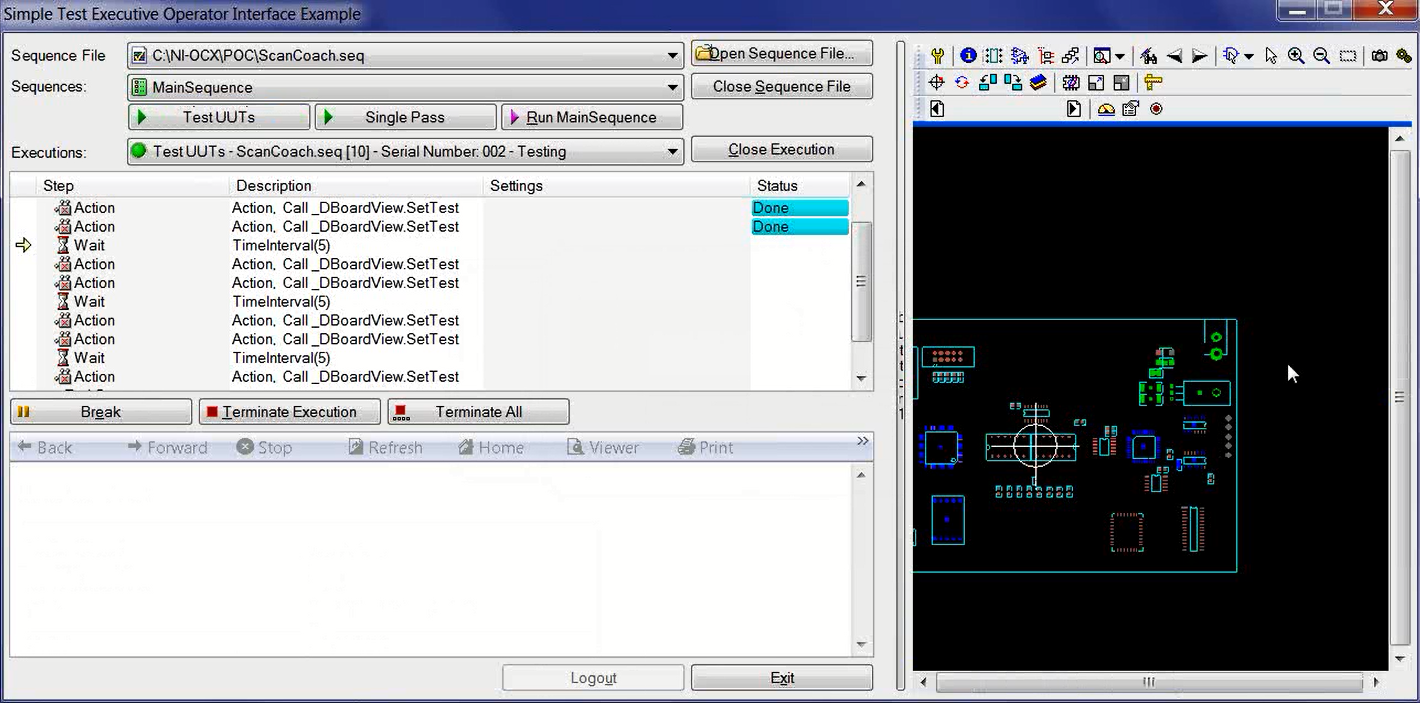

twSystem can be used in the design environment to assist DfT and test coverage analysis at the schematic capture stage as well as during prototype troubleshooting. Within the manufacturing environment, it becomes an integral part of the repair cycle, assisting in the locating of faults and significantly reducing repair time.

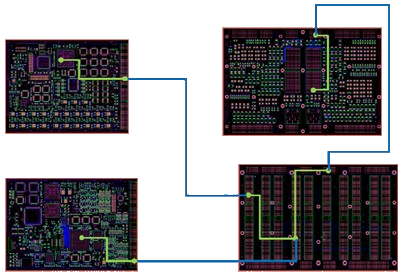

twSystem is designed to import native CAD data for each board comprising the system. In addition, a formal description of the backplane or cables is used to describe the interconnection of the boards.

Product performance is a critical issue in order to speed-up loading, viewing, searching and navigation, even when the system includes more than 10 boards with 3000 components on each.

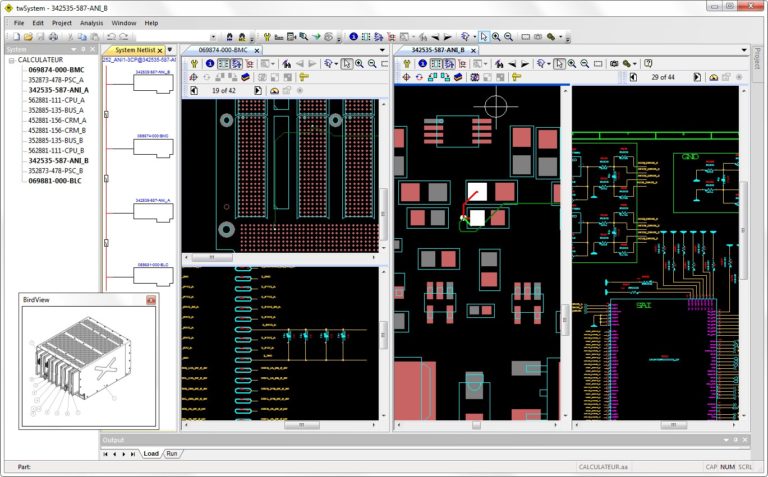

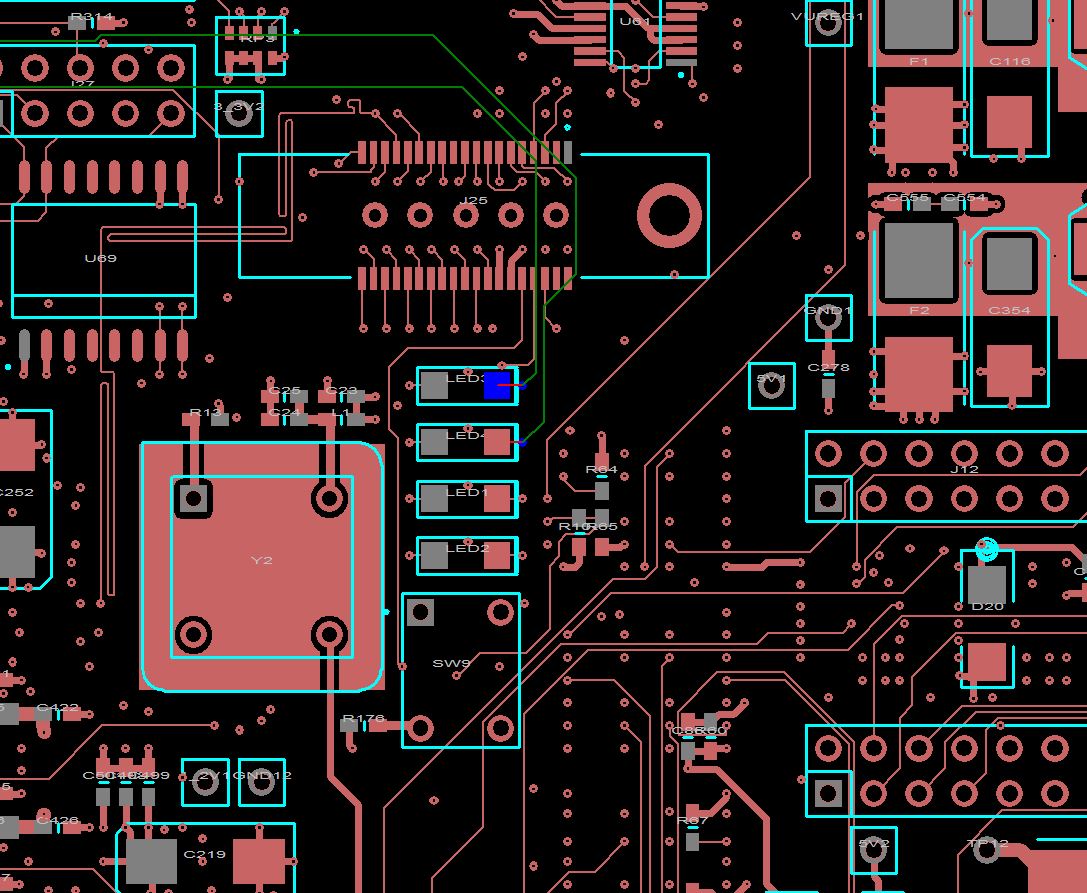

When the CAD data of the system is loaded, twSystem delivers various representations of the system.

List of the boards, backplanes and cables comprising the system. When a board is part of an interconnection, the corresponding connection is highlighted.

Flat netlist view of the full system, which is the foundation for navigation between interconnecting boards within a system.

Mechanical 3D interactive view of the box, including the boards.

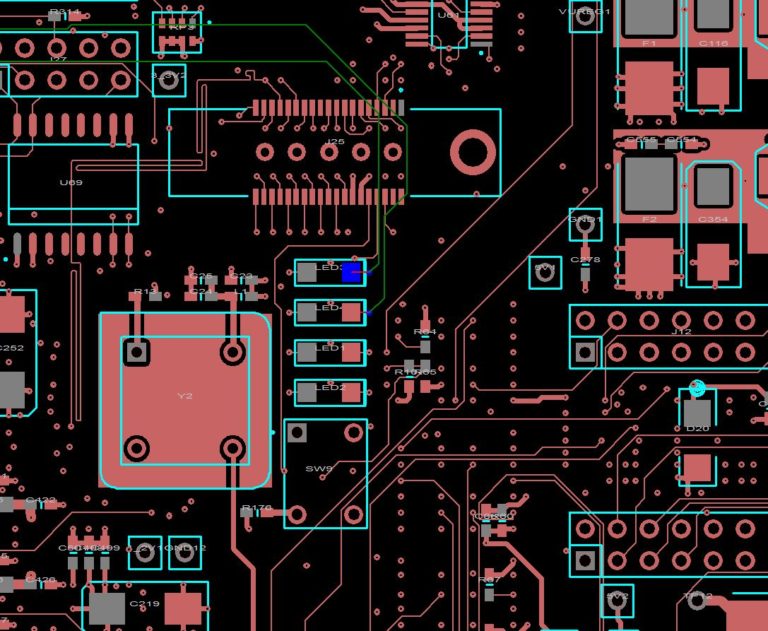

One window for each active board. Each combining the BOM, schematic diagram and CAD layout.