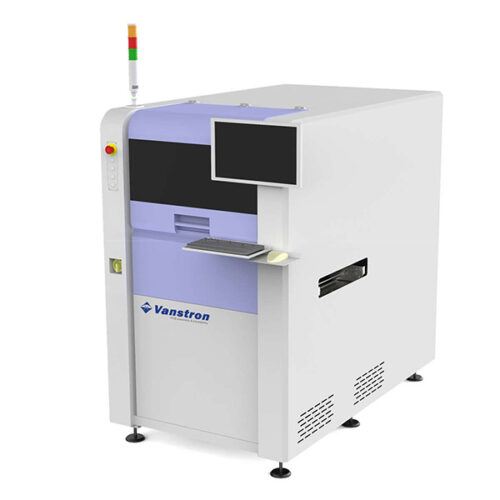

Inline Plasma Treatment for PCB PLS-450

The Vanstron Inline Plasma Treatment Machine is engineered for dry plasma cleaning using atmospheric plasma, ideal for pre-coating cleaning of PCB assemblies (PCBAs). This machine’s design features a plasma head mounted on a Z-axis, paired with an X/Y linear transport system, allowing flexible and precise surface cleaning across any area of the board. With automated control, operators can easily target specific cleaning spots, ensuring comprehensive and controlled plasma treatment.

It’s also adaptable for various materials like plastics, metals, glass, and composites, making it suitable for multiple applications within electronics manufacturing.

Quick Enquiry

If you want to know more about Inline Plasma Treatment for PCB

PLS-450

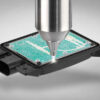

Inline Plasma treatment (cleaning) machine is used for direct dry cleaning with atmospheric plasma before the coating of the PCB.

The plasma head is mounted on the Z axis above the transport system on a linear X/Y axis. The PCB to be cleaning is taken over onto the transport system and transported into the cleaning position, and by advanced automation control technology, the operator is allowed to select the position of cleaning at the any corner on the surface of the board.

- Automated Process: Fully automated system enabling high-volume production.

- Air-Only Plasma Generation: Operates using compressed air alone, eliminating the need for carrier gases.

- Versatile Application: Can function as a standalone system or integrate inline with other production processes.

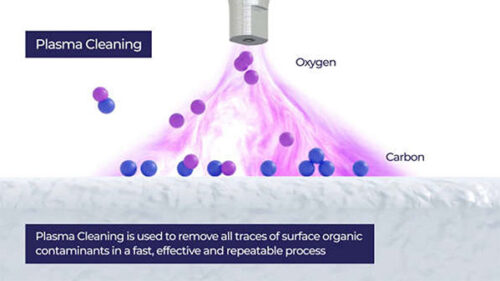

- Eco-Friendly: Uses no chemicals, producing no harmful byproducts.

- Effective Cleaning: Capable of removing dust, oils, greases, and both organic and microbial contaminants.

- Surface Activation: Enhances surface energy for better wetting and adhesion in subsequent processes.

- Standard Safety Features: Includes board presence sensors, UPS, and ESD grounding.

- Operational Alerts: Equipped with a light tower beacon to signal machine status.

- Optional Dual Nozzles: Allows simultaneous cleaning of both sides with dual plasma nozzles.

- Additional Automation Options: Supports add-ons like heavy-duty conveyors, CCD vision camera, and barcode/2D code scanner for enhanced automation.

- Model: PLS-450.

- Work Area: Effective area of 450 x 450 mm (17.72” x 17.72”).

- Clearance Height: Adjustable between 3 – 15 mm (0.12″ – 0.59″).

- RF Power & Frequency: Options of 500 W, 1000 W, and frequencies between 20 – 25 kHz.

- Conveyor System: Automatic width adjustment with pin chain; speed adjustable between 2 – 13 m/min.

- XYZ Axis Configuration: Driven by servo motors with ball screw actuators for precision movement.

- Nozzle Options: Single plasma nozzle, with an option for dual nozzles.

- Operating Speed: Variable speed settings; maximum speed of 800 mm/s and typical working speed of 50-100 mm/s.

- Footprint and Weight: Compact design measuring 900 x 1300 x 1627 mm, with a weight of 530 kg.

- Control System: PLC-controlled with a touchscreen interface, compatible with Vanstron UI and Windows OS.

PLS-450 Plasma Cleaning Systems Brochure: please contact us!