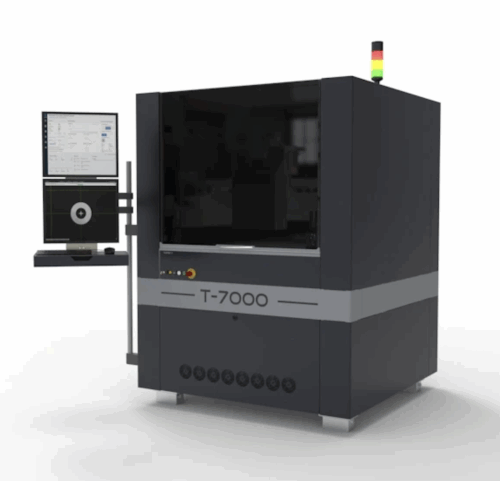

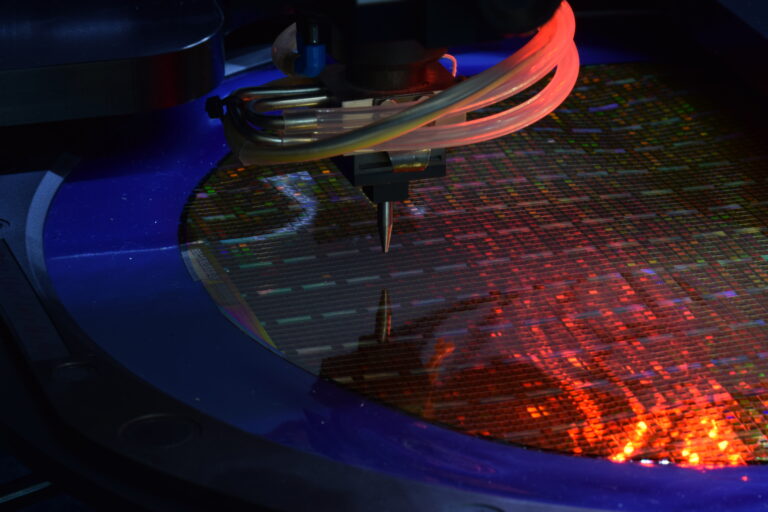

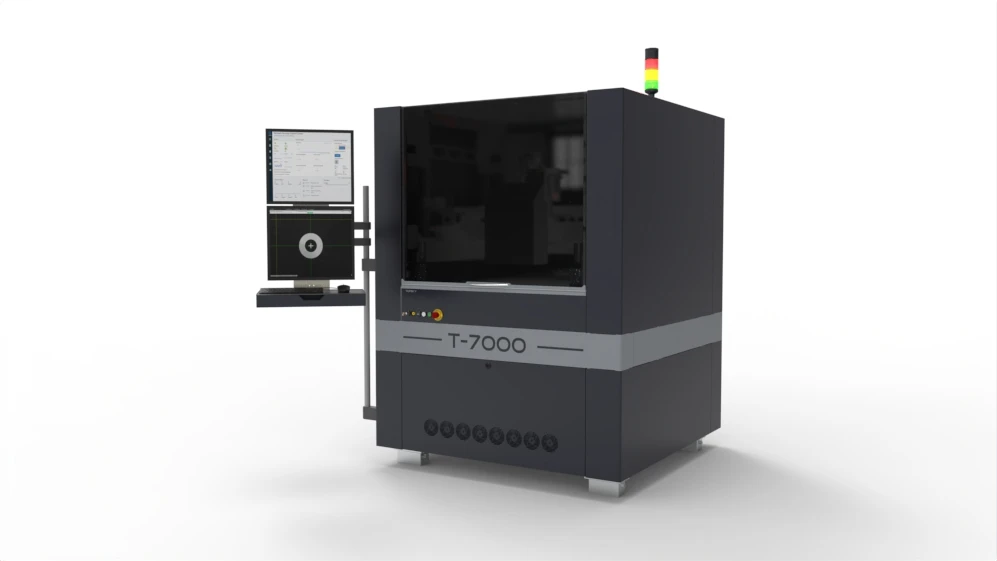

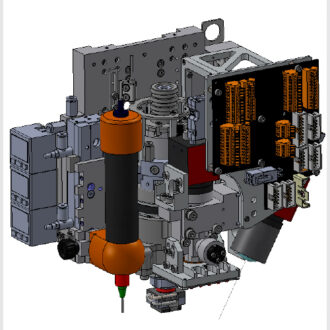

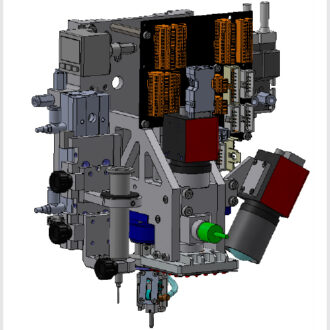

TRESKY T-7000 Photonics Bonder– High Precision Die Bonder for Nano & Opto Electronics

Leader in Micro-Assembly

Technological miniaturisation and functional integration in microelectronics and optoelectronics are essential for future-oriented product innovations. Micro-assembly and assembly and connection technology play a crucial role in the realization of these technological innovations in new and marketable products.

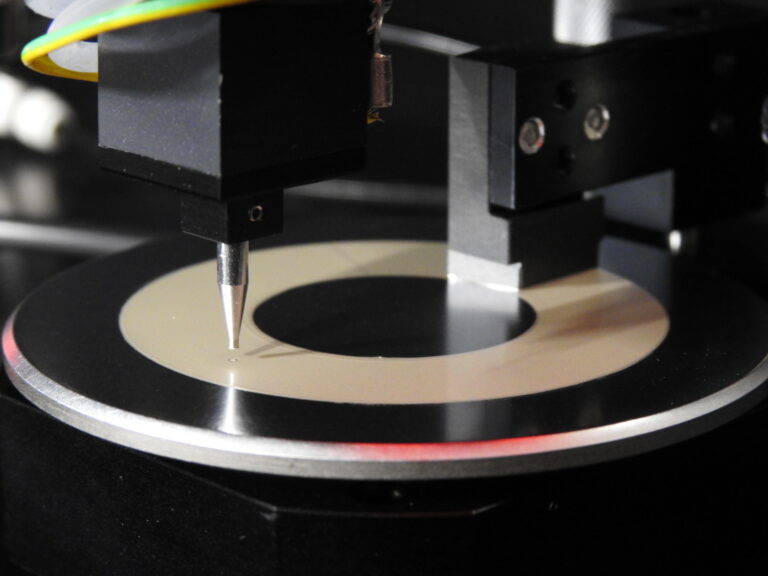

We have developed the T-7000 to successfully realize these requirements. The platform offers sub-micron placement accuracy, a travel range of 500 x 700 mm and a bonding head with minimum bonding forces of up to 0.01 N. On customer request, the bonding force range can be optionally increased to 100 N, 300 N or 500 N.

This model covers all common bonding technologies.

-

Modular design: Fully adaptable configuration for a wide range of applications.

-

High accuracy: < 1 µm placement precision at 3 Sigma.

-

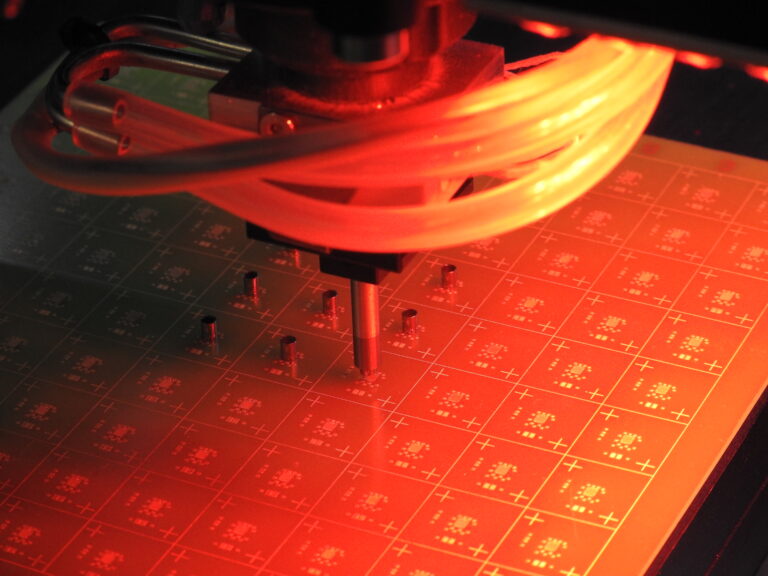

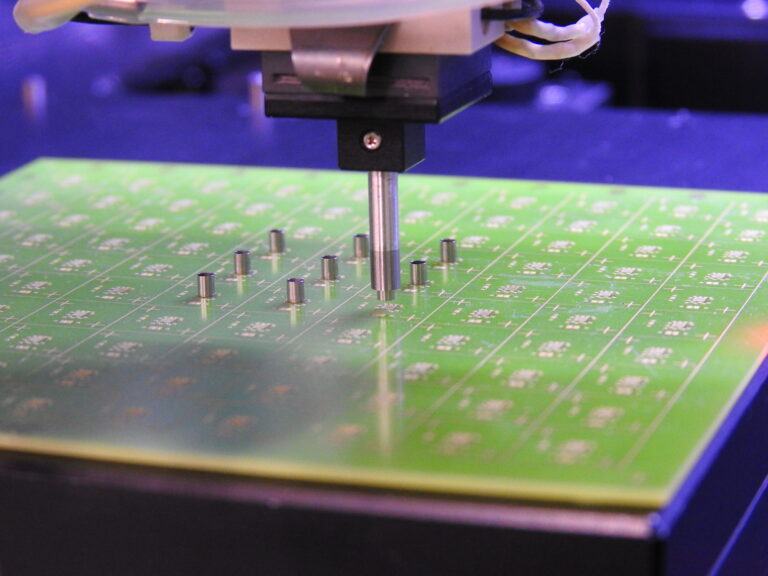

Large working area: Ideal for multi-die and high-complexity assemblies.

-

Up to 300 N bonding force: Optional higher forces available.

-

Flexible integration: Compatible with a wide variety of feeders, bond heads, and automation options.

-

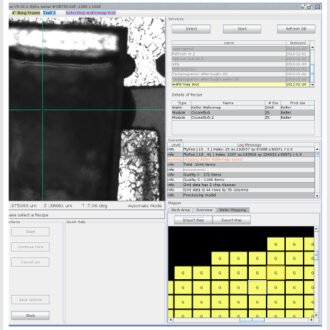

User-friendly software interface: Powerful GUI for programming, recipe management, and traceability.

-

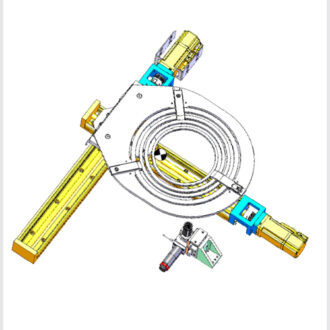

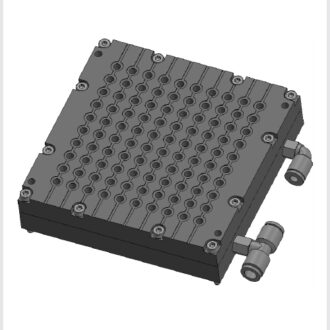

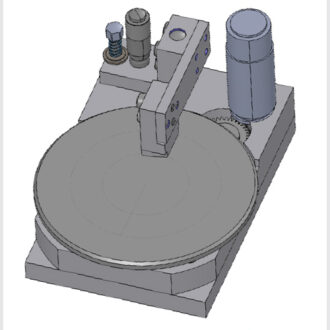

Bonding area: 500 x 700 mm with wafer table

-

Z-axis travel: 100 mm

-

Bond force range: 0.01 – 300 N (higher optional)

-

Placement accuracy: < 1 µm @ 3σ

-

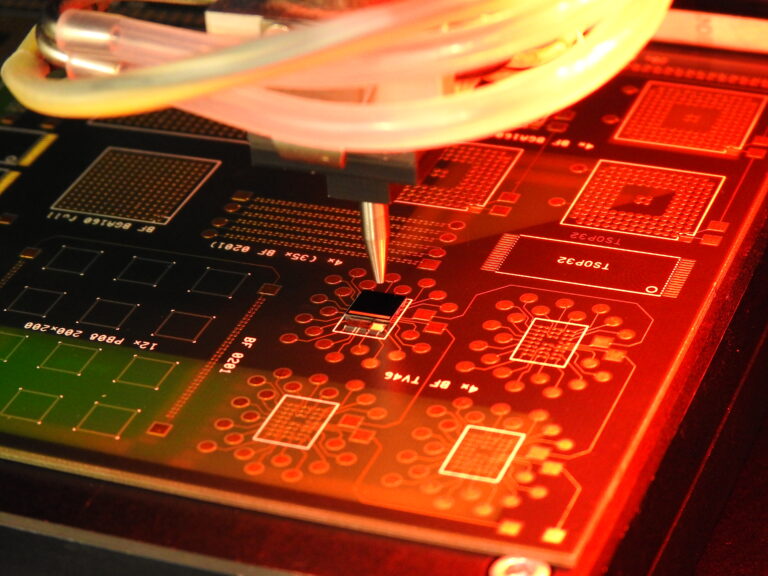

Chip size range: < 0.05 mm up to large format

-

Axes resolution: 0.001 µm (XYZ), 0.005° (theta)

-

Tool rotation: 360°

-

Max acceleration: 2.5 G

-

Photonics packaging

-

MEMS devices

-

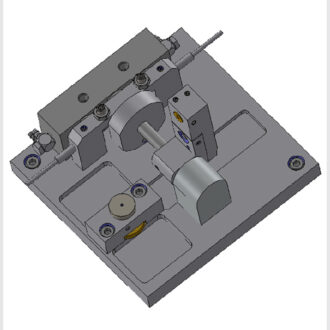

VCSEL & TO Header assembly

-

RFID and smart labels

-

3D integration and SiP modules

-

R&D and pilot production

-

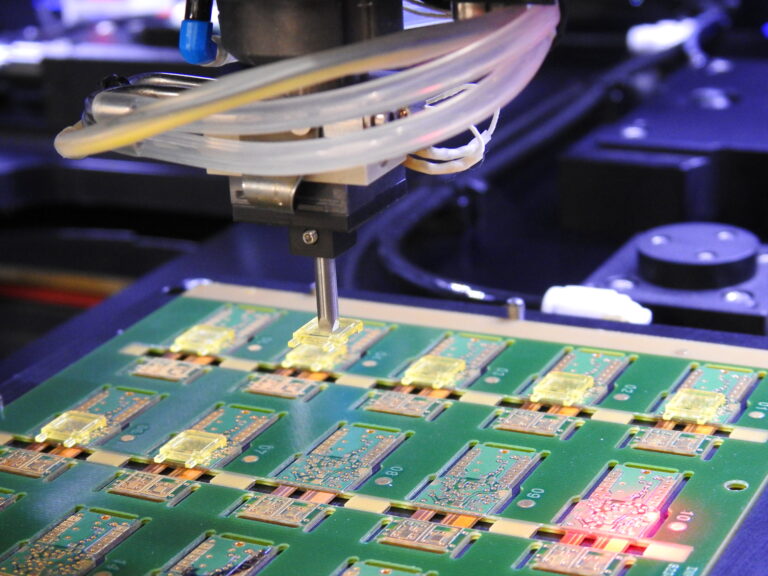

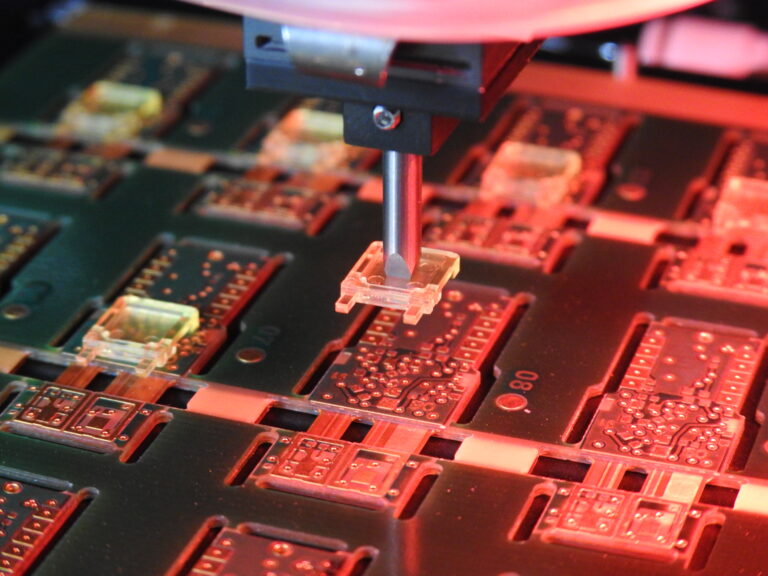

Flip-chip bonding

-

Epoxy & eutectic bonding

-

UV bonding

-

Thermocompression bonding

-

Photonics & glass bonding

-

MEMS & SiP assembly

-

Die sorting and multi-die placement

-

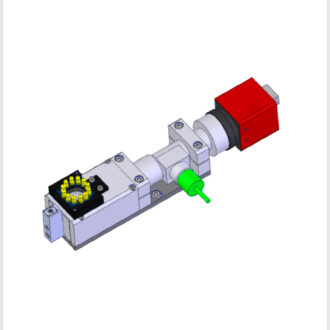

Advanced vision systems with WRGB ring light

-

Heated tools & bonding stages (up to 450°C)

-

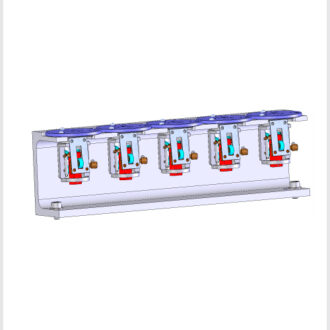

Scrubbing and stamping units

-

UV curing units

-

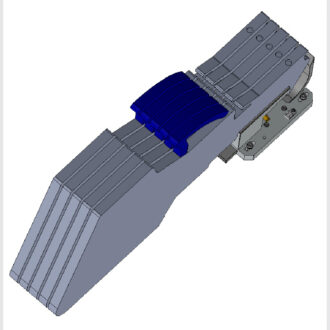

Automatic tool changers

-

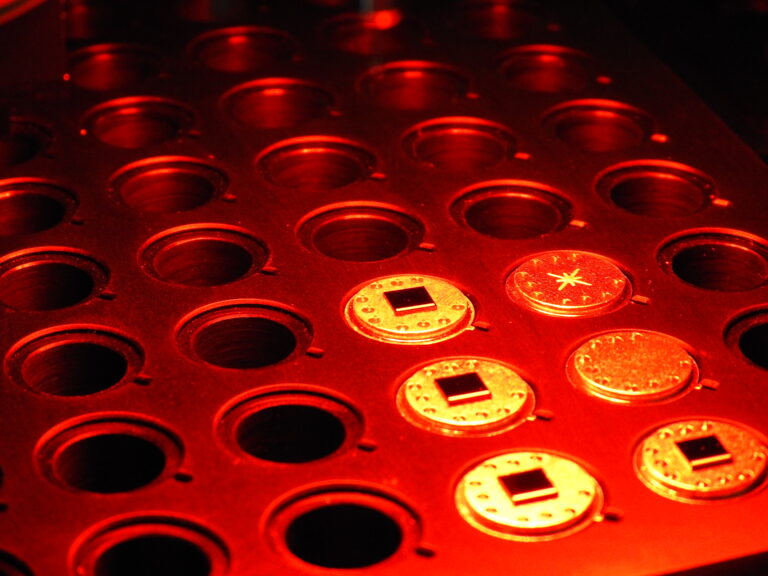

Wafer handling & ejector stages

-

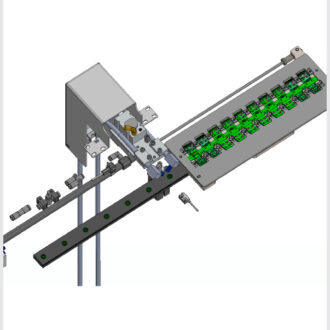

Component feeders (waffle pack, tape, tray, etc.)

-

ID scanning & traceability systems

-

MES integration & wafer mapping

-

Nitrogen or formic acid atmosphere for sensitive processes