The Akrometrix modular approach allows the user to customise a system around his particular needs. The AXP is capable of accepting the complete range of functional modules, whereas other system types have limited options available to them. These options provide upgrades for surface strain and coefficient of thermal expansion assessment, warpage to -50°C, reflow solder process emulation and warpage where the product surface has significant step height changes.

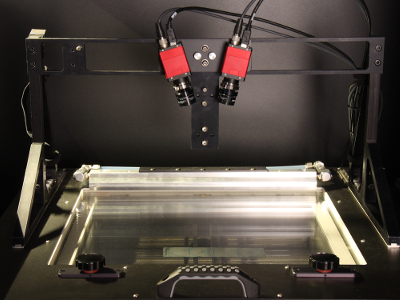

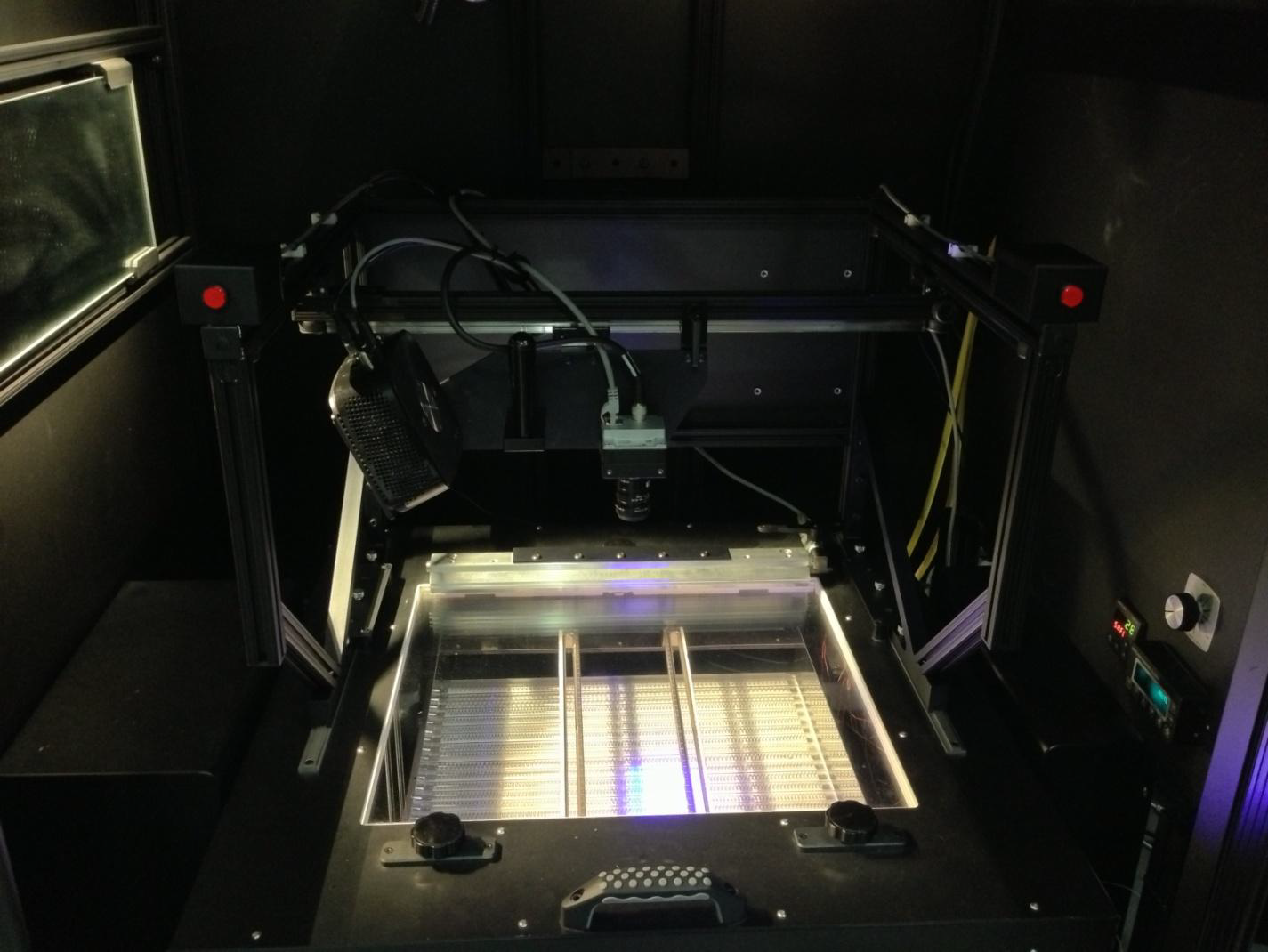

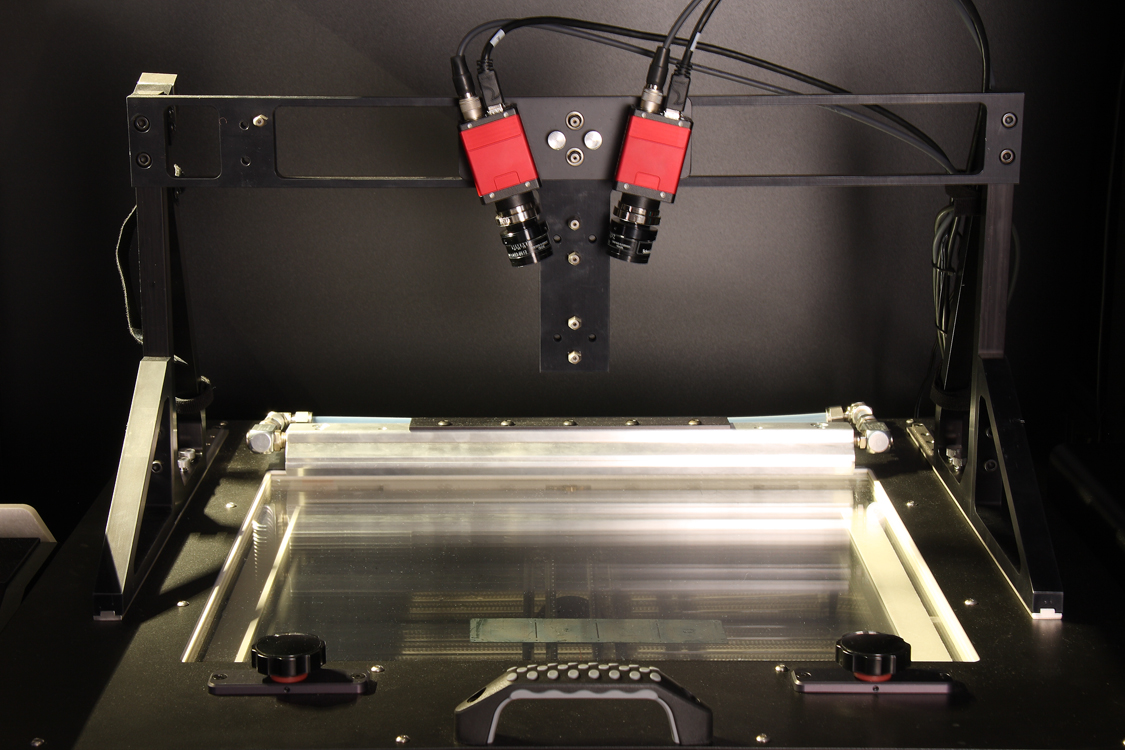

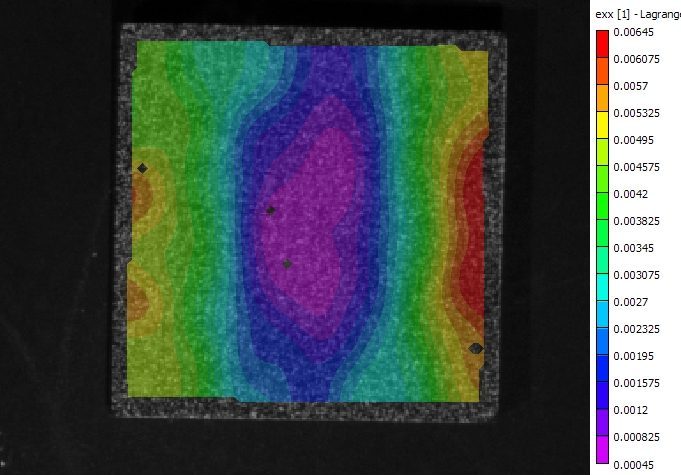

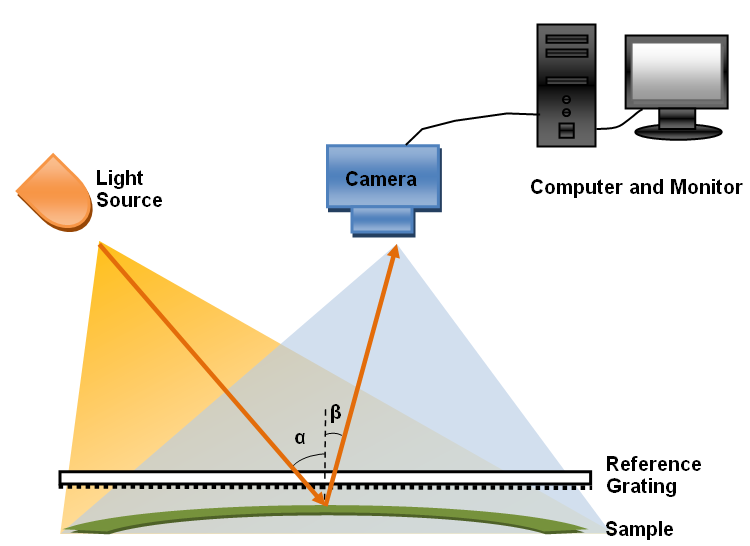

Digital Image Correlation (DIC) is a non-contact, full-field optical technique for measuring both in-plane and out-of-plane displacements of an object surface. A high contrast, random speckle pattern is applied to the surface of interest. Two cameras are mounted above the oven, viewing the sample from different angles. The DIC 2.0 upgrade increases camera resolution and improves strain resolution.

Two simultaneous images from both cameras are digitized. Software identifies the same point on the surface from both perspectives, using pattern recognition of the speckles within a small pixel window. Using the principle of stereo triangulation, the spatial position of the pixel window relative to the cameras is determined in 3D space.

The DIC 2.0 Module is designed to measure in-plane strain with respect to temperature, at a resolution of >150 microstrain, and to use strain data to calculate material CTE (Coefficient of Thermal Expansion).The DIC 2.0 Module is offered on the AXP and PS200S.

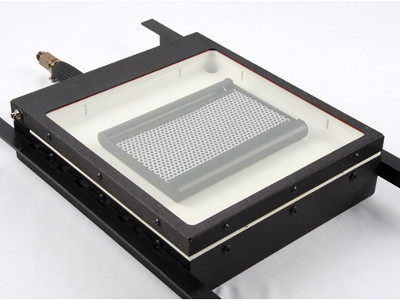

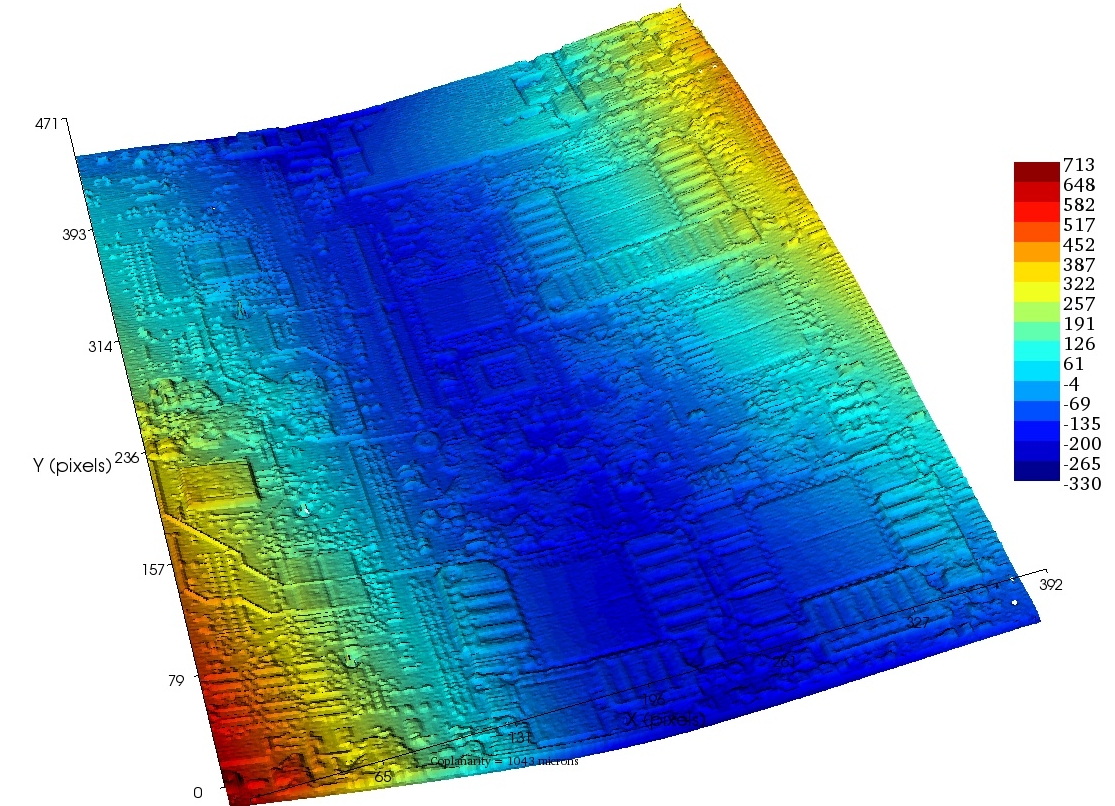

The DFP Module is an add-on for the AXP system. It uses the Digital Fringe Projection technique to measure a field of view of 64×48 mm with a measurement resolution of 5 microns. The DFP Module can be quickly installed on top of the AXP oven with the Shadow Moiré grating removed. The use of the module is fully integrated with the Akrometrix Studio Software.

The DFP Module compliments the Shadow Moiré technique by adding step height measurement capabilities at high data point density. This technique is particularly useful for measurement of connectors, sockets, assembled modules, and PCB local areas.

The DFP Module hardware consists of a 2MP camera, projector, and module hardware. The 64×48 mm field of view is movable around the 400×400 mm oven field of view via a sliding gantry.

The DFP Module is designed to measure out of plane warpage, specializing in discontinuous surfaces, providing high data density of 625 pixels per mm² and warpage resolution of 5 µm with a 64×48 mm field of view. The DFP Module is offered on the AXP.

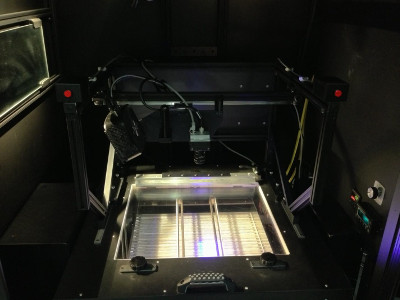

The CRE6 (Convection Reflow Emulation) Module is an add-on for the TherMoiré® AXP system powered by the Studio Software. The CRE6 Module addresses the semiconductor industry requirement for maximum resolution surface measurement and effective reflow emulation with optimized top/bottom temperature uniformity, while utilizing convection heating.

The CRE6 Module enhances Akrometrix’ industry-standard Shadow Moiré measurement technique and offers Z displacement measurement from 2.5 µm down to sub-micron resolution. The CRE6 Module is the fourth add-on module for the expandable TherMoiré® AXP platform.

The CRE6 Module is designed to accurately emulate production reflow conditions for semiconductor packages, at + 3.0 °C/sec heating rate with a sample temperature uniformity +/- 2 °C, and a 70 mm diameter circular field of view. The CRE6 Module is offered on the AXP.

The Convective Module (CM), sub-room temperature flatness measurement module, is used hand-in-hand with Akrometrix’ patented TherMoiré® technology. The module, when coupled with the TherMoiré® system, enables automated phase-stepping analysis and convective cooling down to -50°C and heating up to reflow temperatures. For example, the Convective Module can duplicate reliability testing as required for JEDEC temperature cycling initiative JESD22-A104-B.

The Convective Module comprises a heating/cooling chamber assembly that fits into an existing TherMoiré® oven chamber and a dual stage air cooler. The system accommodates evaluation of a viewing field as large as 200 mm x 200 mm (8 in. x 8 in.) and uses the fully integrated Surface Measurement operating software. The sample enclosure module comes with different sample support nozzle sizes to hold the samples under test. The free standing electronics enclosure houses the temperature controls, heating/cooling devices, over-temperature safety shut-off electronics, fusing and power distribution.

The Convective Module is designed to cool samples down to sub-room temperatures as low as -50°C, and uses convective heat transfer to attain reflow temperatures. It focuses is on reliability style testing as reflow simulation in terms of heating rates and temperature uniformity is not on par with CRE6. The Convective Module is offered on the AXP.