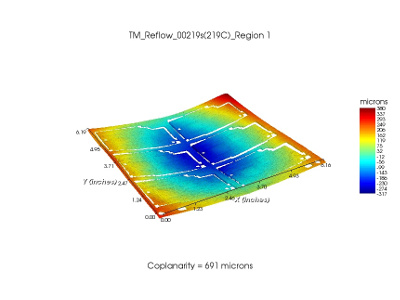

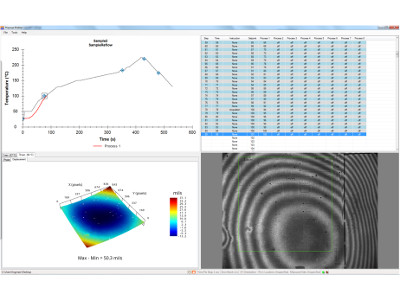

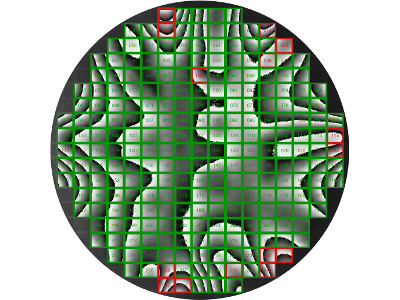

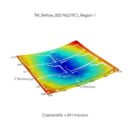

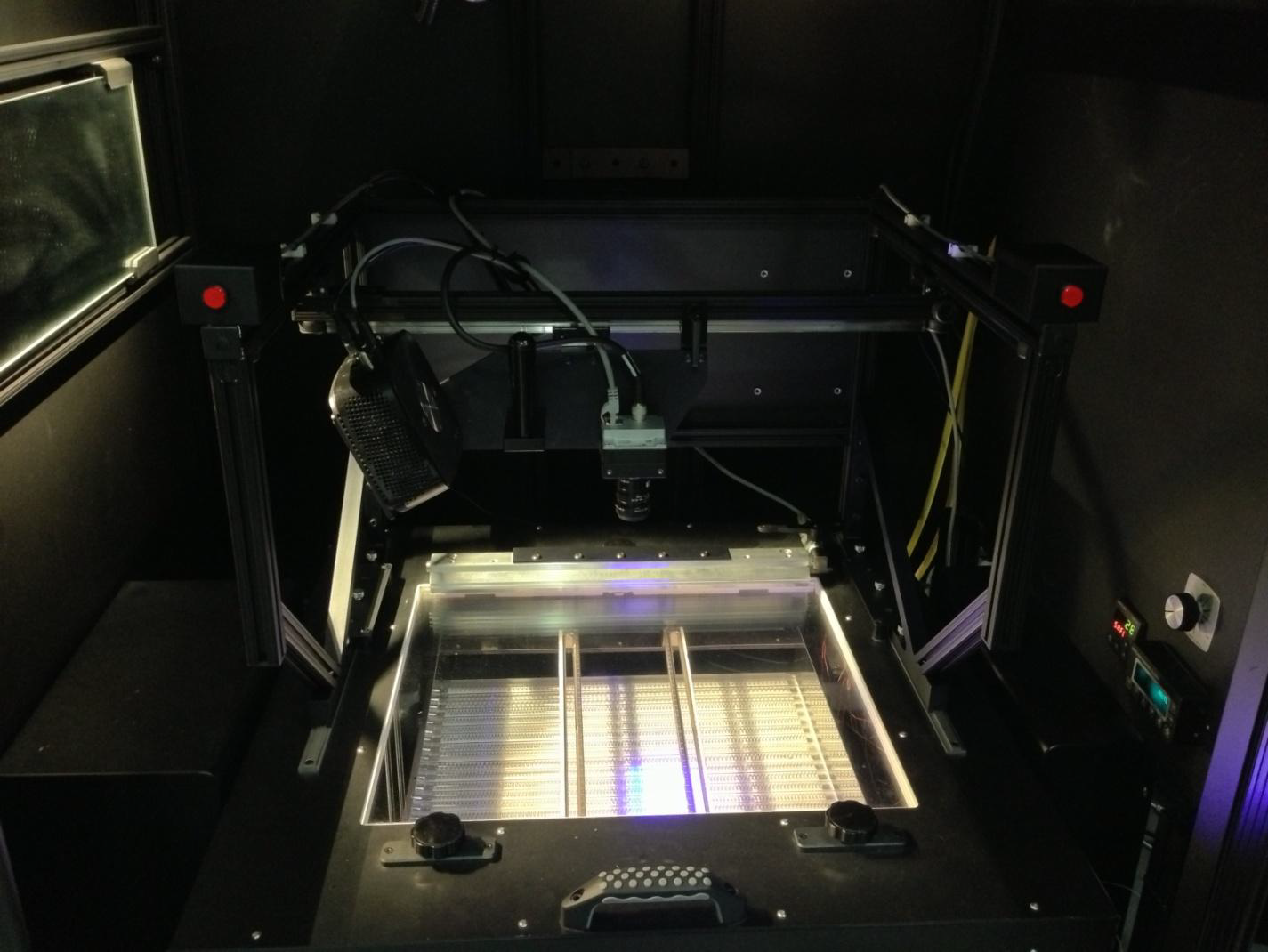

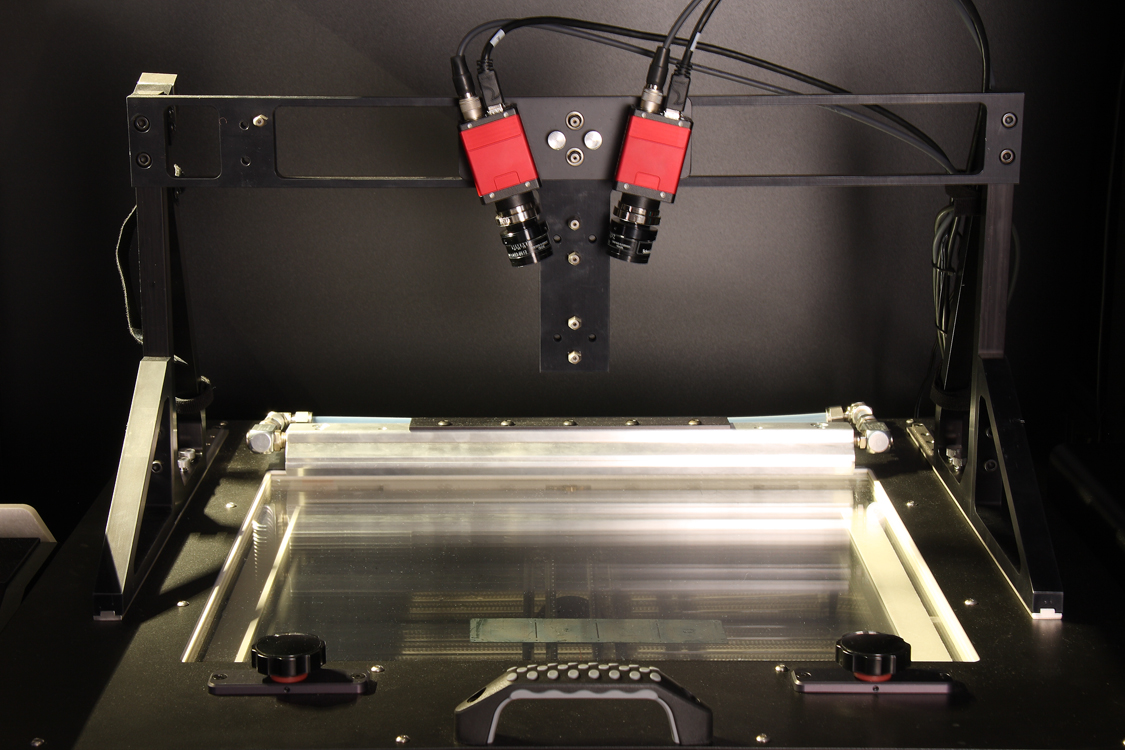

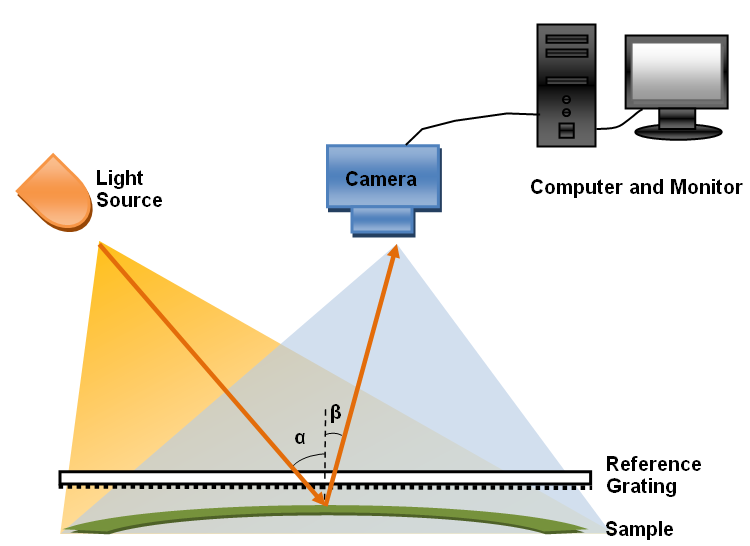

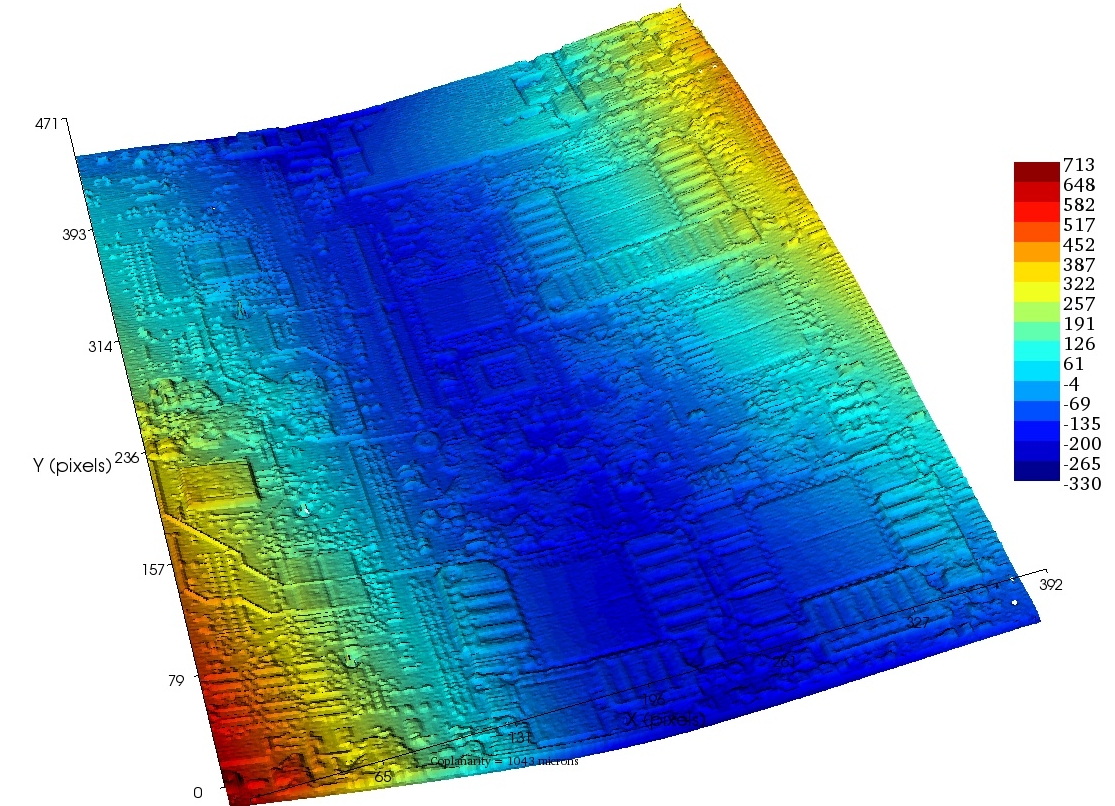

The TherMoiré® PS200S is a metrology solution that utilizes the Shadow Moiré measurement technique combined with automated phase-stepping to characterize out-of-plane displacement for samples up to 150 mm x 200 mm. With time-temperature profiling capability, the TherMoiré® PS200S captures a complete history of a sample’s behaviour during a user-defined thermal excursion.

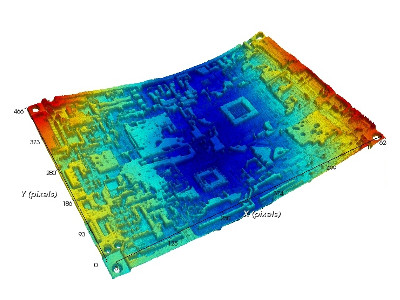

The combination of the Shadow Moiré technique and dynamic temperature profiling is the foundation of the patented TherMoiré® platform. Dynamic profiling is the most effective approach to analyse mechanical behaviour induced by real-world processes and operating environments. Using the TherMoiré® PS200S, engineers will gain a better understanding of the interactions of materials, packages, substrates and complete assemblies, allowing for a thorough analysis of the system and improving its reliability and first pass yield performance. The PS200S is critical to helping meet the ever increasing interconnect and reliability requirements on both the device and substrate levels.

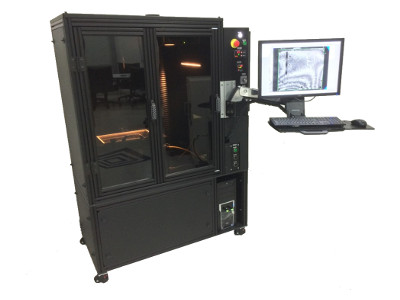

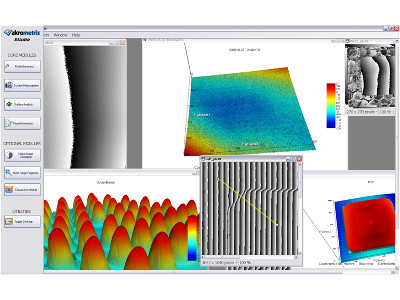

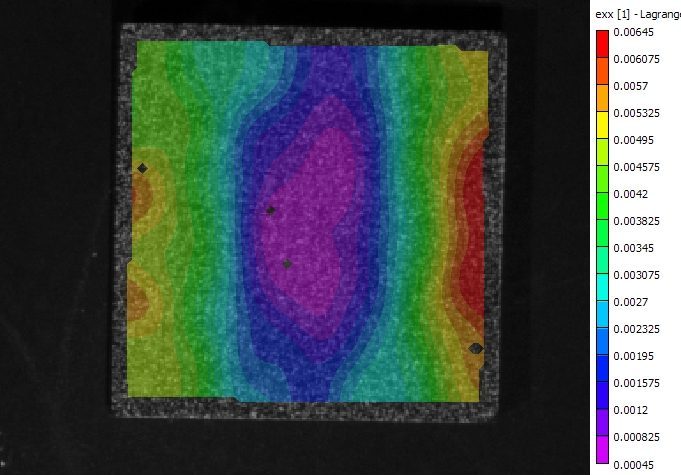

The PS200S is a laboratory solution designed for use in R&D, production and failure analysis/reliability applications, and accepts the Digital Image Correlation module for Strain and coefficient of thermal expansion assessment.