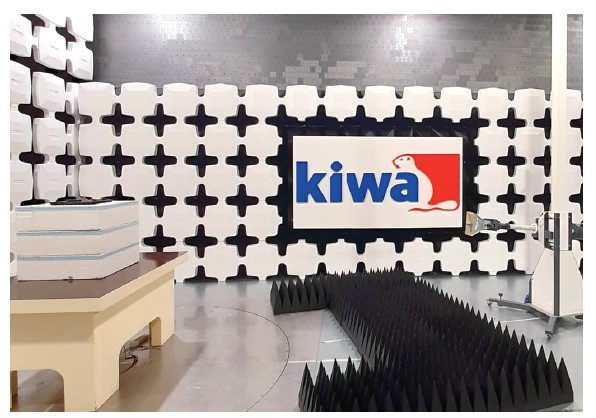

Kiwa and ETS-Lindgren announced the completion of a comprehensive, state-of-the-art EMC test facility in Apeldoorn to service a wide variety of products featuring IoT wireless communication capabilities.

With twelve individual EMC test chambers – all designed, manufactured, and installed by ETS-Lindgren – Kiwa is poised to move beyond its traditional market of testing electrical products in the HVAC and cooking industries, such as heat pumps and boilers. Today, Kiwa tests a very broad scope of products with the advances in IoT technology.

At Accelonix we are proud to have followed this exciting project from the start and on the front row. We were happy to support and facilitate our customer KIWA and our partner ETS-Lindgren along the implementation.

Kiwa selected ETS-Lindgren as their preferred supplier due to the company’s status as a leader in the EMC chamber industry as well as for its reputation for high-quality products. The EMC test chambers ETS-Lindgren provided offer full compliance Radiated Emissions (RE) and Radiated Immunity (RI) measurements, as well as Conducted Transients, Conducted Emissions, ESD, and Radio Testing. The primary chambers include a fully compliant 5-meter Semi-Anechoic Chamber (SAC) and a 3-meter Fully Anechoic Room (FAR) which includes supporting chambers for use as Operator Rooms, Auxiliary Equipment Rooms, and a shared Amplifier Room.

Kiwa’s largest chamber of the multi-chamber project is ETS-Lindgren’s FACT™5 (Free-space Anechoic Chamber Test-site), a full compliance 5-meter chamber with a 3-meter Quiet Zone (QZ). The chamber achieves broadband performance using a unique, optimized arrangement of hybrid and ferrite tile absorber material. Nominal internal shield-to-shield chamber dimensions are 11.7 m L x 6.7 m W x 5.5 m H (38 ft L x 22 ft W x 18 ft H) – prior to absorber installation. ETS-Lindgren also delivered a 3-meter FAR with nominal internal shield-to-shield chamber dimensions of 8.35 m L x 4.83 m W x 3.87 m H (27 ft L x 16 ft W x 13 ft H) – prior to absorber installation. The FACT 5 and FAR chambers provide the highest shielding effectiveness performance available on the market to 125 dB up to 40 GHz, for RE and RI testing in accordance with most international EMC standards.

ETS-Lindgren supplied ten support chambers for various types of EMC testing that ranged in size from a 2 m x 3 m x 2.6 m (6.5 ft x 10 ft x 8.5 ft) Auxiliary Room to a 6 m x 3 m x 2.6 m (20 ft x 10 ft x 8.5 ft) Operator Room.

“Our customers appreciate our knowledge, experience, and the flexibility in our operation,” said Rick Wesselink, Radio Sales Representative with Kiwa Telefication. “They also know from a chamber point of view that we are special since we can test running (gas) appliances. This requires combustion gas exhaust and leak detection equipment. While we will continue this unique test capability, we are very proud of the total setup of our new EMC laboratory. With our multiple high-quality chambers, we now offer a complete service range which fits the latest requirements from the market, including products with wireless communication capabilities.”

“It was a pleasure working with the Kiwa team on this expansive and exciting project,” added Mark Reeve, ETS-Lindgren’s EMEA Regional Sales Manager responsible for the Netherlands. “One of our first tasks was to present a 3D model of the multiple chambers using Building Information Modeling (BIM). Not only did this allow Kiwa to visualize what the new lab layout would look like in the target space, but it also helped the manufacturing team, construction crew, general contractor, architect, and customer understand how the chamber would fit into the building, ahead of the remodeling that was required.”

According to Reeve, the 3D representations showed the mechanical, electrical, and plumbing interfaces, as well as the architecture. “BIM also allowed us to find a solution to the challenge presented by the support steel columns of the parent building which restricted the size of the space available. This meant the 5-meter chamber required a custom design to accommodate the steel columns whilst maximizing the chamber size. With the mechanical design complete, extended RF modeling of the chamber performance confirmed the design met the RF performance required. It was a challenge at the start, but our veteran team of experts ensured a successful project outcome. We are thrilled to see Kiwa’s growth in EMC test capabilities.”

Did you know ETS-Lindgren is the only true turnkey EMC systems supplier, manufacturing 90% of the components of an EMC test facility? These components include RF shielded enclosures, doors, penetrations, electromagnetic absorbers, power line filters, CCTV monitoring systems, turntables, antenna towers, emission measurement and field generation immunity antennas, field probes, power amplifiers, instrumentation, and measurement software. ETS-Lindgren’s vertical integration capabilities, supported by six manufacturing factories and more than 700 employees worldwide, nearly eliminates reliance on third parties and subcontractors. In addition, ETS-Lindgren chambers are designed, engineered, manufactured, installed, integrated, and serviced by in-house professional teams.

For more information on the new Kiwa EMC Test Facility, view the case study here. Click here to take a virtual facility tour.

Contact us for more information on the ETS-Lindgren line of chambers, shielded chambers, semi-anechoic chambers, full anechoic chambers, reverberation chambers and more.