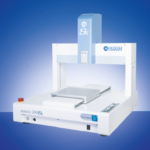

The TRAK series plasma system delivers superior plasma treatment quality and automation in one very configurable platform, resulting in high-throughput plasma processing and plasma cleaning for semiconductor and electronics packaging. The plasma chamber is capable of processes such as dielectric etch, photoresist descum/ash, oxide removal, organic contamination clean and surface activation, depending upon chamber kit and electrode configuration.

TRAK systems support manual and automated operations (with inline or built-in handler), SMEMA and SECS/GEM communications protocol, and remote user interface. The versatile, exceptionally uniform, and compact chamber design allows for interchangeable processing configurations and plasma modes – direct, RIE, downstream, and IFP (ion-free plasma) plasma treatment options.

A three-axis symmetrical plasma chamber ensures that all positions of the product are treated uniformly while tight controls over all process parameters ensure repeatable results from product to product.

- The TRAK’s small plasma chamber volume and proprietary plasma process control enable unmatched short cycle times, while its slim structure minimizes floor space requirements.

- The TRAK’s universal architecture handles a wide variety of product form factors, including boats, carriers, Jedec/Auer® boats, strips, laminates, and wafers.

- Depending on throughput and product form requirements, the system can be configured for magazine-to-magazine processing of single and multiple strips or lead frames, wafer processing, and standalone for island-based production environments.

- The TRAK’s SMART® Tune management system provides closed-loop plasma control that optimizes the RF system and minimizes tuning time. The system automatically recycles to a plasma-ready state, compensating for changes in vacuum pressure, temperature and varied lot sizes. Maximum power to the chamber is achieved in seconds with a proprietary algorithm that constantly measures forward and reflective power inside the chamber.