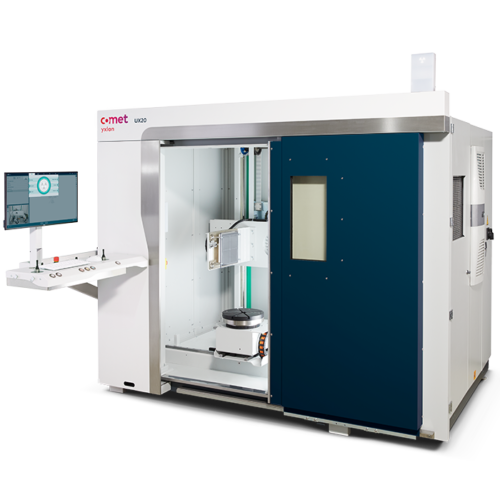

Effortless X-ray and CT inspection of cast parts

Due to the transformation to electric mobility, foundries are increasingly producing larger and more complex components.

With its exceptional inspection envelope and the smart Geminy software, the UX20 facilitates fast and precise inspections of cast parts and helps increase overall production efficiency.

Which parts can be inspected with the UX20?

- Automotive and aerospace castings

- Welded structures

- Multi-material components

- Additive manufactured parts

- Special alloys

- Plastics and fiber-reinforced composites

- Ceramics

Which applications is it designed for?

- Quality assurance and material analyses

- Failure analyses e.g., flaws, porosities, cracks, inclusions

- Assembly checking

- Measurements of inner structures

- First inspections

- Small series inspections

- Spot-check inspections

- Process control