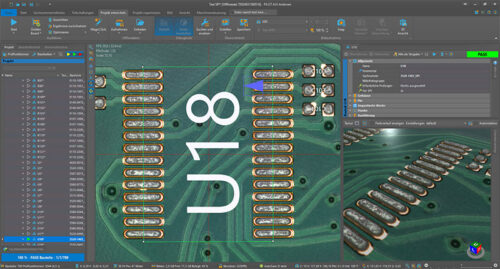

The inline inspection system for printed solder paste is characterized by a wide measuring range. Conventional solder pastes with a height of 80 μm to 150 μm can be measured just as well as sinter pastes with a height of only 20 μm. The system is available in various configurations.

The solder paste depots are inspected with 3D technology with measurements of shape, height, area, bridges, volume, x/y offset and coplanarity.

The sinter paste inspection also includes the detection of particles, notches, holes and frayings in the depot.

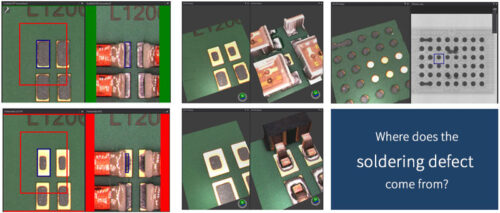

The SPI system is essential for prevention of soldering errors:

- Early fault prevention

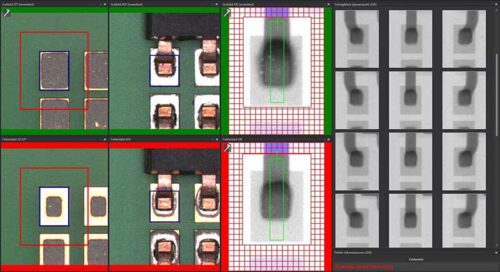

- detection of paste deposition defects

- assemblies with detected solder paste defects sorted out after paste printing

- Monitoring of stencil printing

- correct position of the solder paste depot

- measures the solder deposit volumes and solder volume distribution

- closed loop feedback to the screen printer