Define, provision, and deploy robust IoT device security with easy-to-use tools, and a flexible as-a-service model.

OEMs require robust hardware and software security for IoT devices to protect their brand and meet regulation, data privacy, and safety requirements.

The best design approach is to build hardware-based security into their products.

Interested? Request a datasheet here

Data I/O SentriX Removes Roadblocks to Deploying Security

The complexity of IoT hardware-based security creates roadblocks OEMs, Electronic Manufacturing Services (EMS), Contract Manufacturers (CM), Programming Centers, and Silicon vendors face deploying solutions:

Commercial Benefits

- Low upfront cost

- No minimum order quantities

- Per part as-a-Service model

- Offer a premium value-added and revenue-generating service

- Upgrade an existing PSV5000 or PSV7000 to SentriX

|

Ease of Use

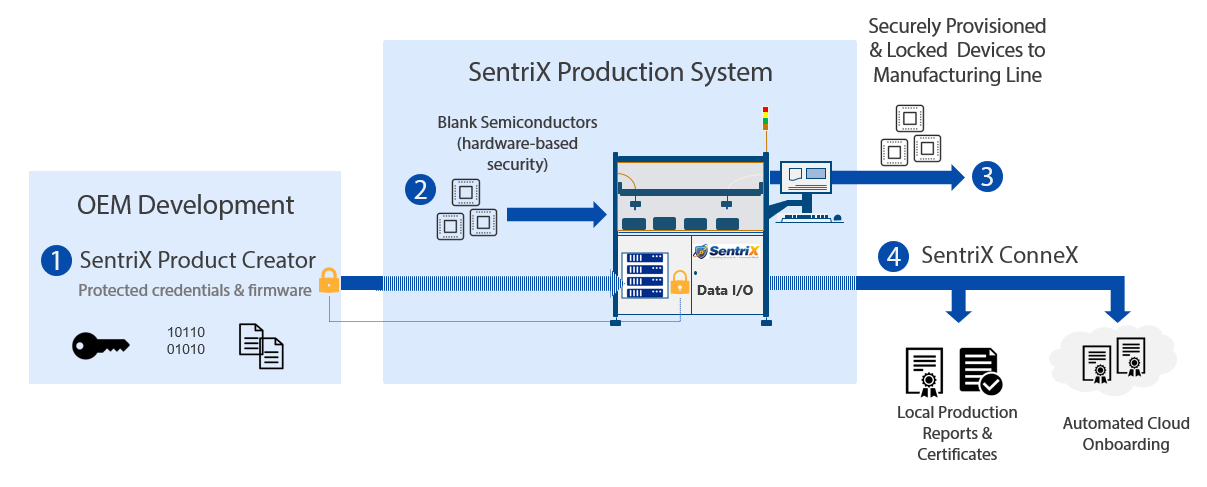

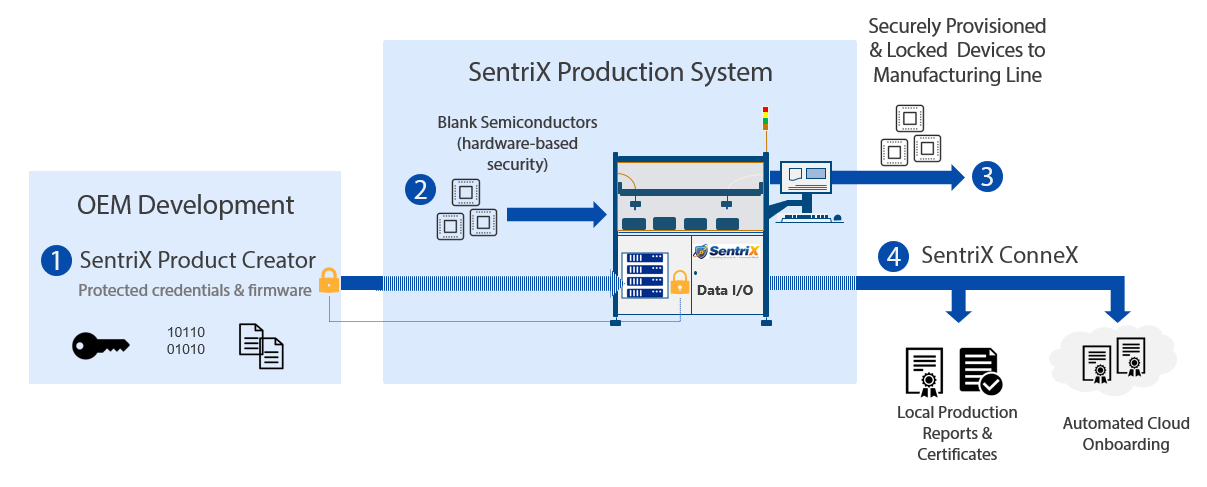

- Integrated software tools for design to production

- Intuitive collaboration tools

- Low or high-volume production

- Preconfigured security use cases

- Optional services, eg. Automated cloud onboarding

|

Robust Security

- Pre-manufacturing assembly security deployment

- Authenticates parts

- Cryptographic protection of secrets and firmware

- Supports silicon hardware Roots of Trust

- Production equipment with integrated FIPS 140-2 Level 3 compliant hardware security module (HSM)

|

How SentriX Simplifies IoT Security: