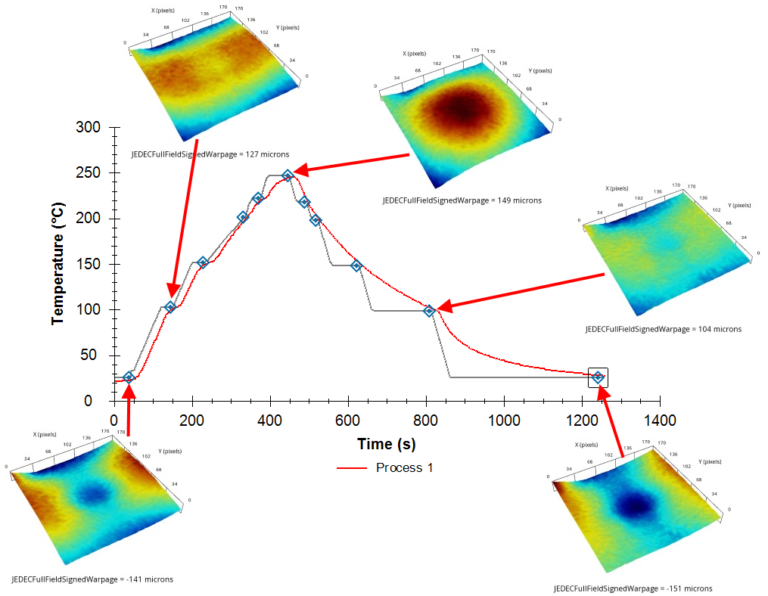

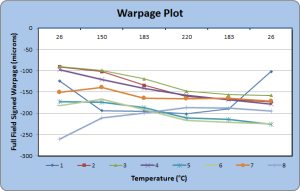

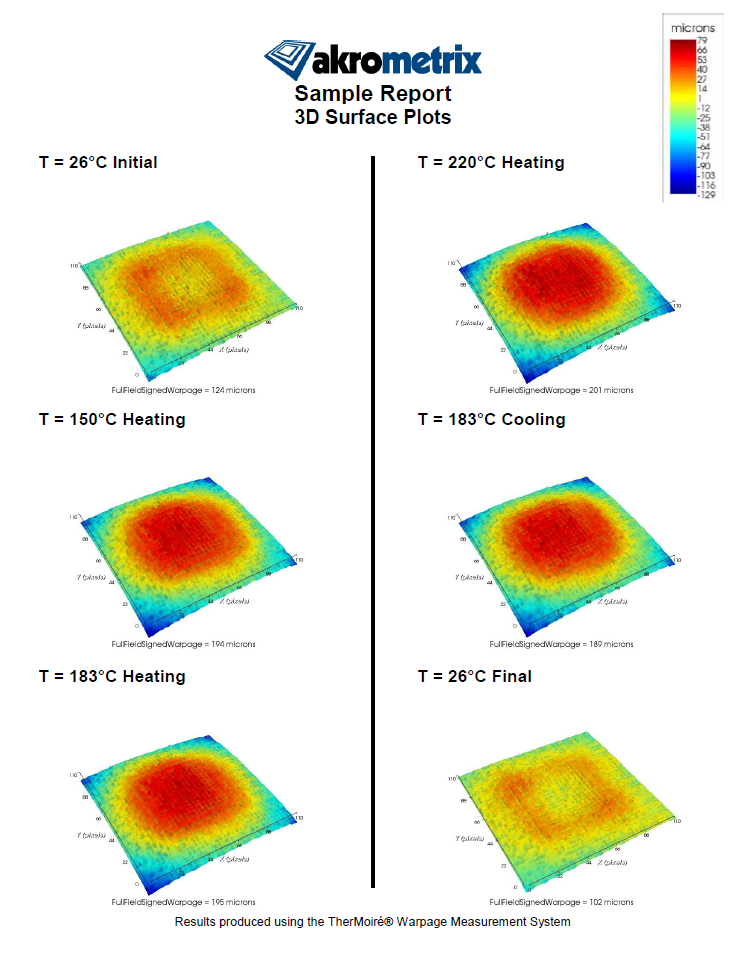

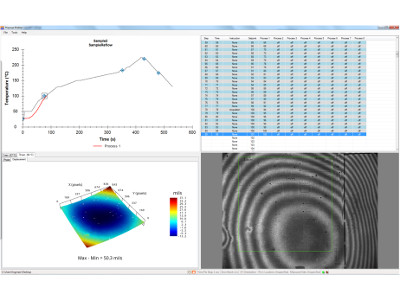

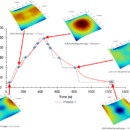

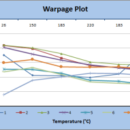

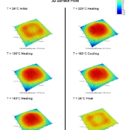

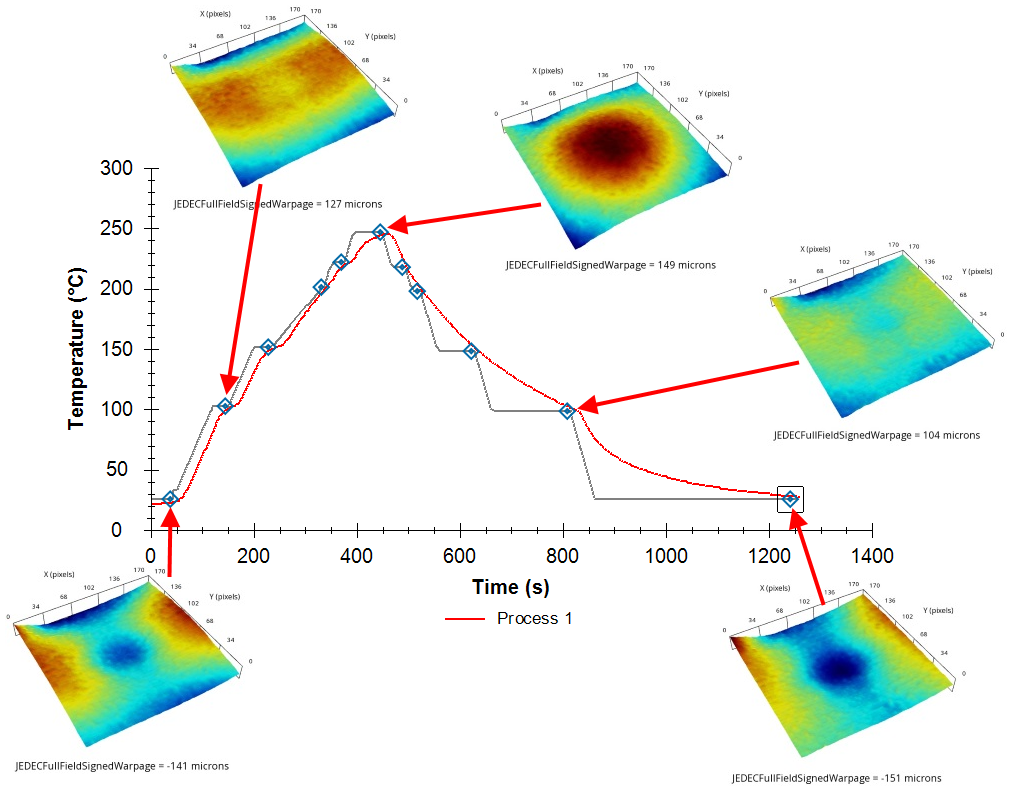

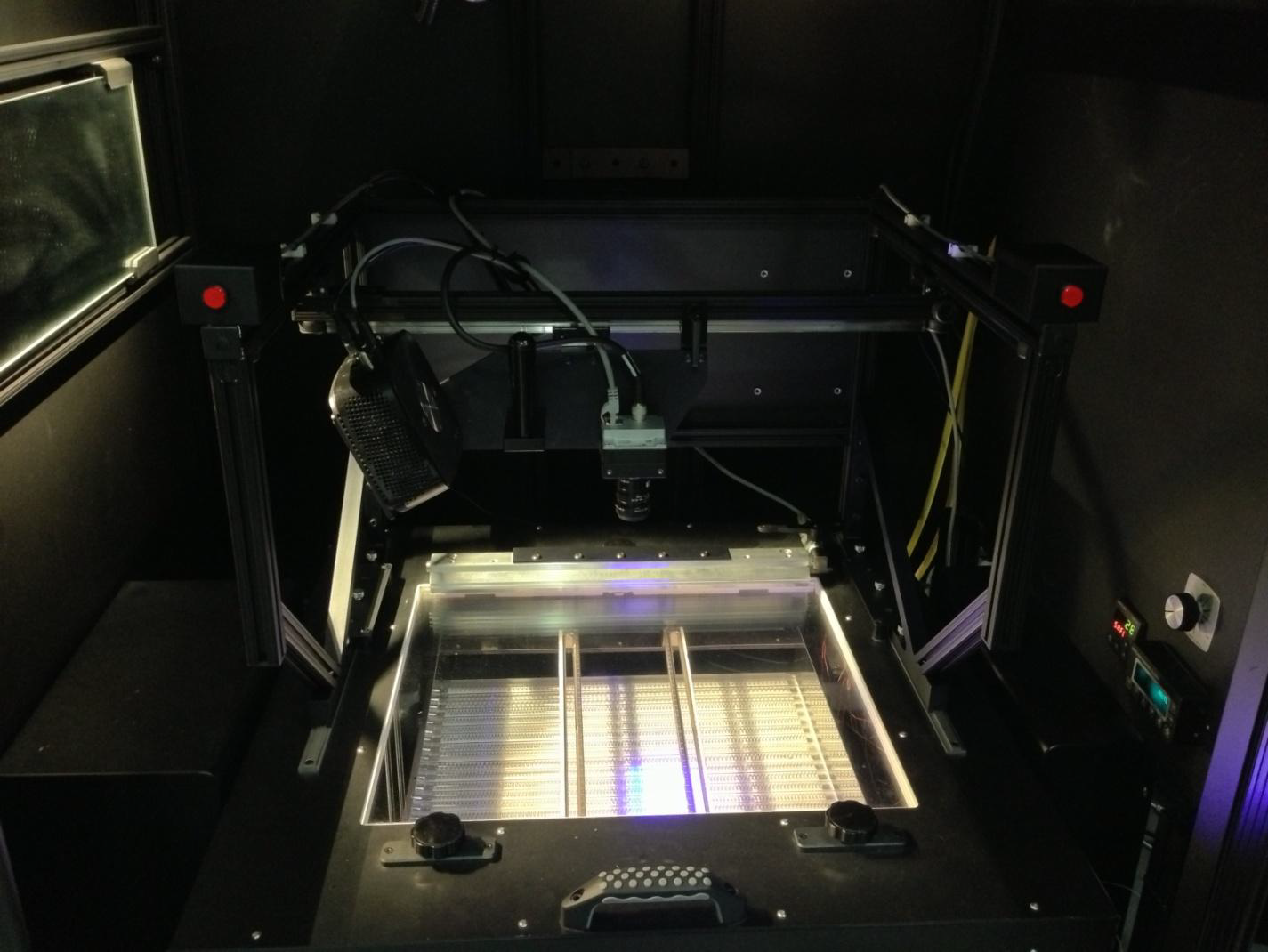

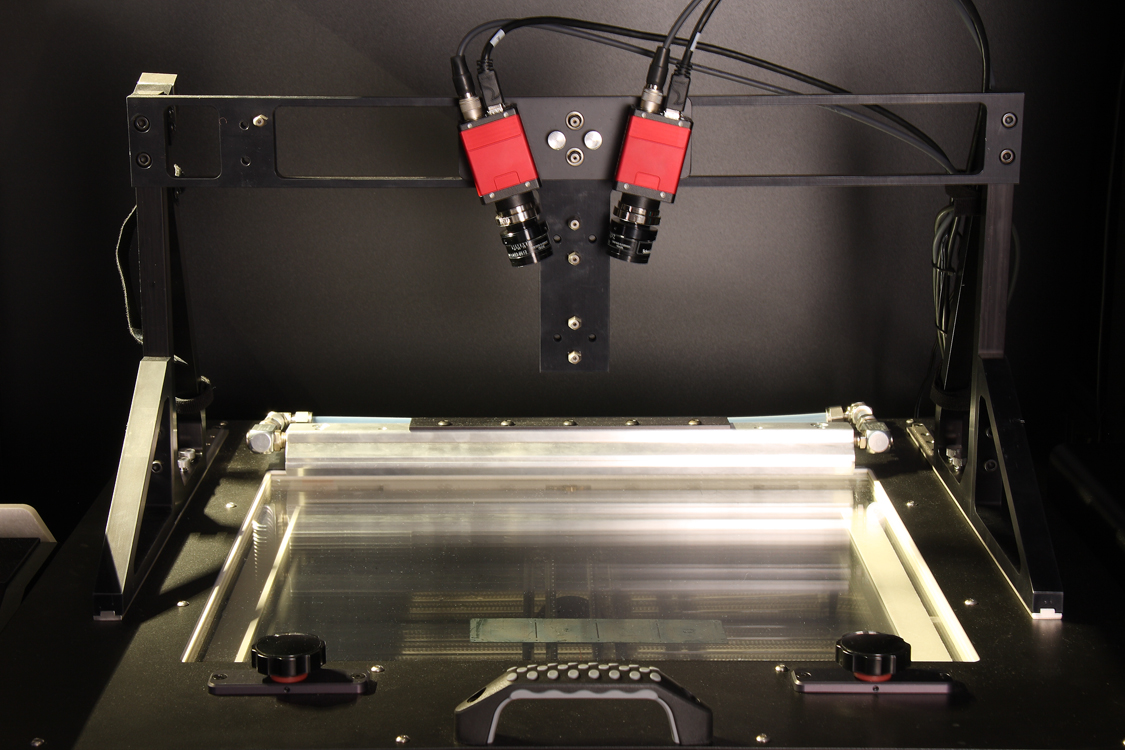

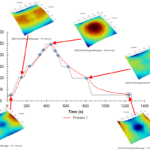

Akrometrix’ flatness characterization and analysis solutions provide sub 2-second data acquisition during dynamic temperature profiling. Profiles can be customized to match heating rates found in production ovens. Standard pricing includes 6 discreet measurement points along a profile of your choice.

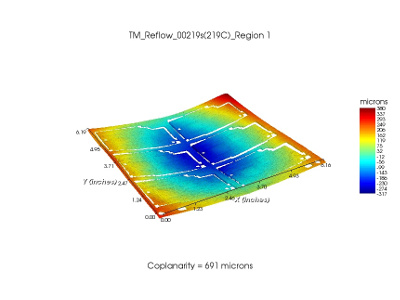

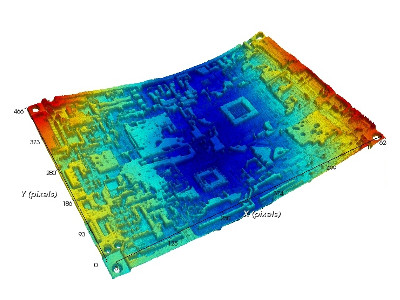

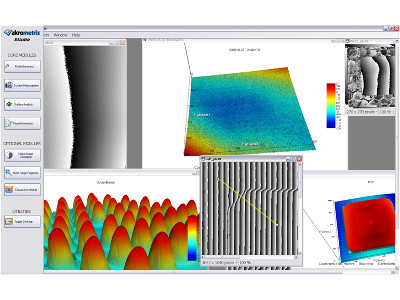

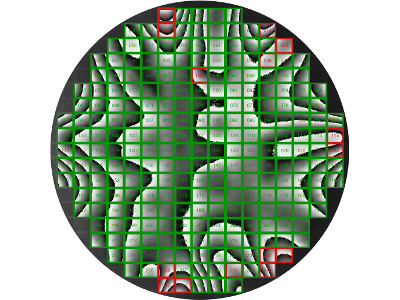

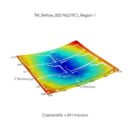

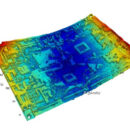

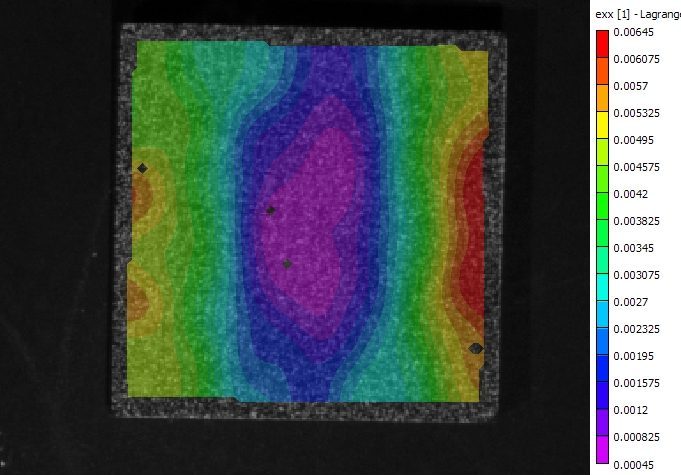

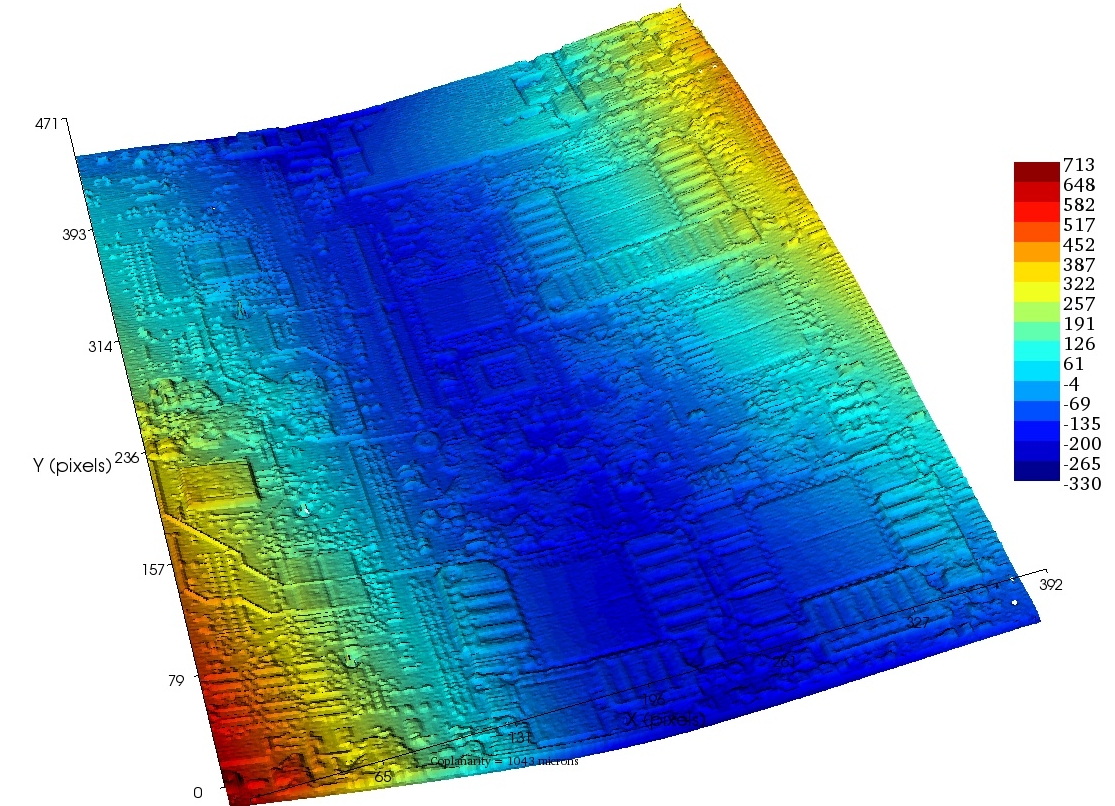

Akrometrix encourages its clients and prospects to visit its Atlanta, Georgia testing facility to participate in the testing process and review the results in a customized data format consisting of 3D surface plots, 2D contour mapping, 2D diagonal plots, coplanarity tables, and displacement matrices to enable better understanding of the data. Our application engineers are always available for data interpretation.

Sample Flatness Testing Applications:

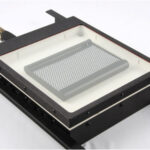

- PCB/substrate characterization at temperature

- Pb-Free processing implementation

- Validation of Finite Element Modeling (FEM)

- Supplier performance and conformity monitoring

- Evaluation of different materials and constructions

- Failure/defect analysis

- Machined component flatness checks

- Check out our Testing Applications Document for a more complete look at the kinds of samples that can be tested with our measurement techniques.

Services are available on a per part or project basis. Turnaround time ranges from 2 days to 10 days, depending on volume of testing required