The 3D AOI Generation by Goepel electronics!

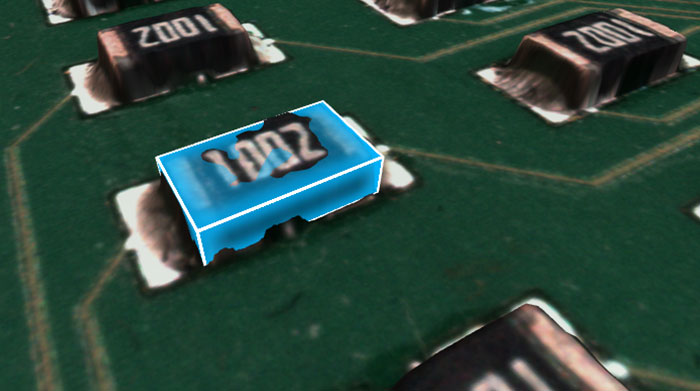

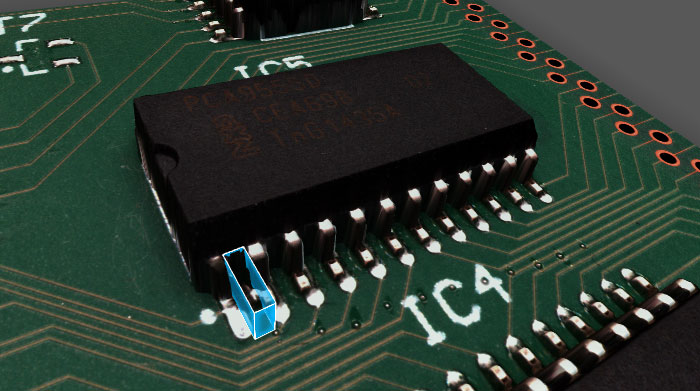

Optimized 3D camera module for increased error detection and reduced pseudo errors

- Maximum fault detection

- Variable 360° inspection in 1° steps at constant resolution and definition

- Unique multispectral and multidimensional illumination

- Combined 2D/3D technologies

Highest optical quality for projection and image acquisition

Dynamic adjustment of inspection parameters

Measurement of components up to 35 mm

Inspection of optically critical surfaces with large dynamic range

Optionally available: 3-segment belt module for reduced handling time by several seconds